Spring 2017 Prosthetic Hand: Solidworks Fingers Design

The Robot Company | CEO Professor Gary Hill

Blog Post Created by Project Manager | Bianca Esquivel

Project Designs Created by Manufacturing and Design Engineer | David Mendoza

Table of Contents

Introduction

To make this project look more humanoid and match the customer’s finger size, the fingers, which were acquired from Inmoov, needed to be adjusted. The finger lengths and diameters had to be scaled, so that they can approximately be similar to the customers other hand.

This process is performed in response to requirement:

L1-9 Appearance: The prosthetic hand shall be approximately the same size as the customer’s other hand.

Index Length: 9 cm

Middle Length: 10 cm

Ring Length: 9 cm

Pinky Length: 7 cm

Thumb Length: 10 cm

L2-7 Appearance | System

The prosthetic hand should have a humanoid design such that most integrated parts will not be visible, corresponding to the customer’s measurements: Index Length: 9 cm, Middle Length: 10 cm, Ring Length: 8 cm, Pinky Length: 7 cm, Thumb Length: 10 cm, and Palm Length: 11 cm

Process

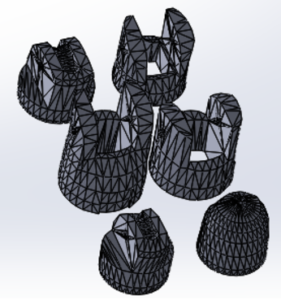

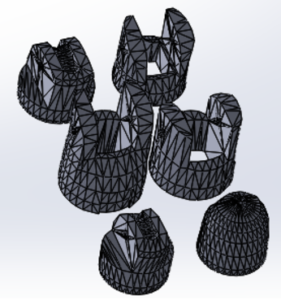

The fingers used for the Hand are scaled fingers that were used in the Inmoov [1], by Langevin, the link to his fingers were given in a CAD file on thingiverse [2]. The file that were give were STL files, which cannot be modified, but since these fingers were the type of fingers that we wanted use. We just need to scale them so that they match the same finger length of your customer Ernesto, as shown in figure 1.

The sizes of Ernesto’s fingers are:

Index: 9 cm long 2 cm diameter.

Middle: 10 cm long 2 cm diameter

Ring: 9 cm long 1.75 cm diameter

Pinky: 7 cm long 1.6 cm diameter

I was able to put the STL into Solidwork, with the help of Gill on grab CAD showing me how to do this [3]. After looking at the files for the fingers, I found out that I could not change the way the fingers looked, but after looking at Rafi tutorial [4] found that I can scale them. Since the model fingers, that we were going to use, had the shape of regular fingers, I only needed to scale the length of each finger. While trying to scale each finger, I did make a mistake on using the index finger and my prime model for scaling each finger. What I found out was that the scaling can have a huge effect to the holes if they are scaled too much. Even though the index, middle and ring finger were not affected by the scaling, the pinky finger did not come out so well. The second time I scaled the fingers I did them from the original files that I got from Langevin,

The original sizes of Langevin Inmoov Fingers:

Index3: 9.51 cm long 1.77 cm diameter

Majeure3: 10.2 cm long 1.9 cm diameter

Ringfinger3: 9.07 cm long 1.6 cm diameter

Auriculaire3: 8.17 cm long 1.4 cm diameter

To get the scaling factors that were needed to get the Inmoov fingers to get the same length as Ernesto’s.

Scaling Factor=Ernistos finger size/Inmoov finger size=9 cm/9.51 cm=0.94637224

I was able to do this for the four fingers, as seen in figure 2, the thumb was a little harder to calculate. This was because I did not know where I should measure the thumb from on Ernesto’s hand. The thumb in the first measurement was about 10 cm, but this was to include the part that connected it to the servo. Since I hand to redesign the part that will connect the thumb to the servo, I took that length out and resized the thumb to be 7 cm in length. After resizing the thumb I designed the part that will connect the thumb to the servo that is shown in figure 3, I modeled it similar to the Thumb-Hinge from the act hand [5].

Results

When the fingers were assembled, they were approximately the sizes that were needed for the project. The string that was used to pull the fingers went through the holes in the fingers then glued and screwed together. Once the palm was finished and printed, the fingers would be glued on. Once they were on the palm it was seen that they were not able to grasp anything and were not positioned correctly on the palm so that they can reach far enough to grasp something with the thumb.

Conclusion

Looking at how the fingers were designed in the previous generation and comparing it to how these fingers came out. It can be seen that the previous generation fingers used a lever in the middle of the fingers so that they did not have to use too much of their string to pull the finger. The fingers from the previous generation, had a better position to move close enough to be able to grasp a cup. The fingers from the Inmoov fingers would have worked better if the palm was able to have two parts and be able to bend with the fingers.

Link to Solidworkds Finger Files:

References

Langevin, G. (n.d.). Hand and Forarm. Retrieved April 30, 2017, from http://inmoov.fr/hand-and-forarm/

Langevin, G. (2012, February 18). Hand robot InMoov by Gael_Langevin. Retrieved May 04, 2017, from http://www.thingiverse.com/thing:17773

Gill, S. (2012, June 1). How do I convert STL graphics to a solid model? Retrieved May 04, 2017, from https://grabcad.com/tutorials/how-do-i-convert-stl-graphics-to-a-solid-model

Rafi, F. (2014, January 1). Tutorial: How to scale stl in solidworks? Retrieved May 04, 2017, from https://grabcad.com/tutorials/tutorial-how-to-scale-stl-in-solidworks

S, P. (2016, May 12). Tact: Low-cost, Advanced Prosthetic Hand. Retrieved April 30, 2017, from http://www.instructables.com/id/Tact-Low-cost-Advanced-Prosthetic-Hand/