Fall Biped 2016- Design Document

By: Hector Martinez

Approved By: Ijya Karki (Project Manager)

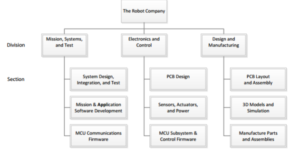

Table of Contents

Introduction

Requirement

The Biped design correlates to all level 1 and level 2 requirements because the body will house all components.

This design document reviews the design process for Biped starting at week 9 of the semester. Up until week 9, the manufacturing engineer for Biped was Ijya Karki and I was co-engineer for manufacturing of Prosthetic Arm. Having done my research on prosthetics and robotic arms, I had zero knowledge of biped robotics. With two weeks until CDR, I had a steep learning curve. In order to be an effective addition to Biped, I had to understand the current design, model it on SolidWorks, and build a prototype. There was no time for me to research biped technology or come up with a new design so we had to move forward with the group’s current design.

Version 1

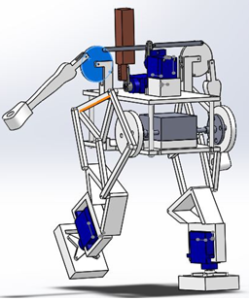

The Biped design at week 9 featured a weight shifting body, dual dc motor gearbox, shaft encoders, and servos. Weight shifting would be controlled by the servos, one servo would shift weight left and right to aid in walking while the other servo would shift weight front and back to assist with incline walking. Shaft encoders would help track the position of each foot which would aid in coding. Everything would be housed in a multi layered body. This current design was under review by the current group and there were changes they wanted to make, I was asked to review the design and make changes necessary to ensure walking. I was also tasked with developing a turning mechanism because the current design did not have a way to turn.

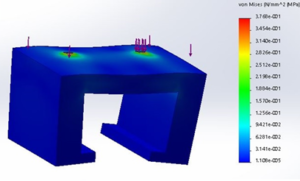

Fig. 1 – Design of the Biped at week 9 of the semester.

While simulating on SolidWorks, I discovered the walking mechanism was unstable and a more robust system was necessary. Based on the above design, the group wanted two motors that powered the legs connected at the front and the back of the legs, opposed to one at the front, we believed this would solve the stability issues while walking. I came up with the idea of adding servos at the bottom of the feet to assist with turning. Adding servos to the bottom of the feet would create ankles, we would then attach new feet to the servo to complete a turn.

Version 2

Fig. 2 – Preliminary drawing of how arms could be used to balance Biped.

Before I start modeling on SolidWorks I always put ideas on paper, by doing this, I can start to think about what aspects of my ideas are feasible. For example, figure 2 is a drawing of an initial idea I had for arms that could be rotated forward or backwards with servos to help when walking on inclines. Seeing it on paper, I realized that this design would not help with level waking because there wasn’t a way to extend the arms out to the side to shift center of mass left or right. By putting my ideas on paper first, I was able to quickly realize that this idea was not useful for Biped. Had I decided to simulate on SolidWorks only, I would have spent considerable time designing before coming to the same conclusion.

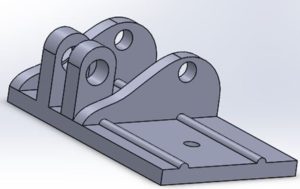

Fig. 3 – Ver. 2 of Biped design, featuring a servo at the ankle that will assist with turning.

The group believed that instead of having a body capable of shifting weight, a simpler approach was to have weighted arms capable of rotating 180 degrees on the horizontal plane. This would accomplish level walking as well as walking at an incline. Figure 3 features the servo housed in the leg with a foot attached with a servo gear. While the Biped is mid step, it has to balance on one foot, if the servo is turned in this position the whole Biped can turn and complete the step in a new direction.

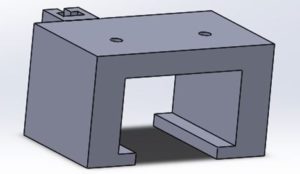

Fig. 4 – Ver. 2 of Biped, featuring two motors to power the legs and the servos inside the body to power each of the arms.

By rotating the arms forward or back, the Biped would be able to shift its weight forward or back while walking on inclines. While taking a step on level ground, one of the arms would extend out while the other arm is rotated forward. This will shift the center of mass of the biped to one of the feet so the free leg can take a step. Figure 4 features the two servos inside the body which would control each arm. Below the body are the two motors that will be used to control the legs. One motor is connected at the front link of the leg while the other motor is connected to the rear link. The legs would have to be 180 degrees out of phase with each other to produce walking.

One week before CDR, the customer was asked to review the progress of the current design and to our surprise he was not pleased with any part of it. The customer had concerns that the feet were too far apart and weight shifting would not be accomplished. He liked the idea of having arms to shift weight, but did not like that the arms were extended out at all times. Apparently there was some miscommunication as to the number of motors the customer wanted to use for walking, he wanted the Biped to accomplish walking using only one motor. The only thing the customer liked about version 2 was the servos at the ankle to accomplish turning.

Version 3

With a clearer vision of what the customer wanted, I needed a crash course on robotic walking. I sought the help of Aaron Choi the manufacturing engineer for Velociraptor and he pointed me in the direction of the Theo Jansen Biped (TJB) toy. The TJB featured a single crank shaft to produce walking and ball bearings which acted as weights to shift weight while walking.

Fig. 5 – Theo Jansen Biped toy that would become the inspiration for the final Biped design.

By incorporating a single shaft to produce walking, we would be able to use a single motor. The customer insisted on using arms to control weight shifting, therefore, we did not look into incorporating ball bearings as a mechanism in version 3 of our design. At this point, I was extremely overwhelmed and I was seriously questioning my new found abilities on SolidWorks. Luckily, Aaron had 8 weeks of research on Theo Jansen walking technology and helped me, a lot. With his help, I was able to produce version 3 of Biped.

Fig. 6 – Preliminary sketch/design of Ver. 3 of Biped, featuring Theo Jansen linkages and a single motor.

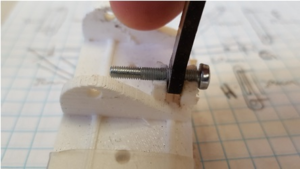

For version 3 of Biped I decided to get really creative in the way I would incorporate the servo into the Theo Jansen linkages. As can be seen above, I decided to house the servo in between the bottom triangle of the Theo Jansen mechanism. I believed that adding a servo to the bottom of the triangle would cause Biped to be too tall and possibly unstable. Brandon Perez, our mission systems and test (MST) engineer, provided me with a motor that featured a single shaft which extruded from both sides of the motor. I could use this motor to attach the legs to the shaft at 180 degrees out of phase to produce walking. Additionally, the width of the motor and single shaft gave the Biped a total width of 5cm, versus 9cm from previous versions.

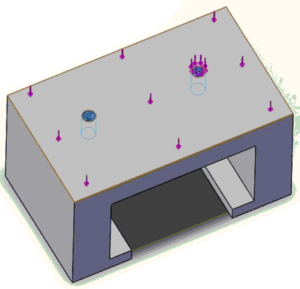

Fig. 7 – Ver. 3 of Biped. Additional features include servo controlled arms that hang to the side, TJB legs, servo controlled weight at the top to control incline walking.

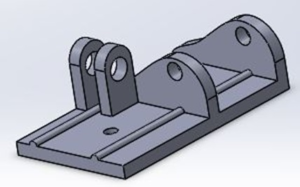

I continued designing taking into consideration our requirements. One requirement was to have color sensors that would be able to sense color pads on the floor. The figure above doesn’t show the sensor housing, but the reason for the boxy feet is because the sensors would be housed under the feet. We concluded that the best place for the color sensor would be as close to the floor since that’s where the color pads would be located. The figure below shows how these feet were designed as well as how the servos would attach to the feet.

Fig. 8 – Design sketches of color sensor housing as well as servo/foot mate.

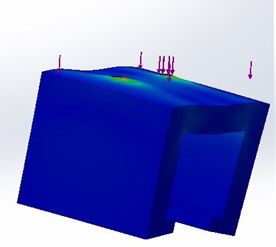

For CDR, we featured a Biped which we expected to look much like the final product. I added weights to the arms and top rear servo to simulate weight shifting for level walking and walking on inclines. The motor, servos, PCB, and 3Dot were all at their final locations. The faint outline of a body can be seen in the figure below. We were very pleased with this latest design and were confident the customer would be as well.

Fig. 9 – Design presented at CDR featuring attached weights, PCB, and simulated walking.

Unexpectedly, we were received a lot of criticism for our design. Once again, the customer complained about the width of the feet. The customer raised concerns that the Biped was too wide and would like the legs to be much closer together. The customer did like how the arms could move, but did not like how the design was implemented. The customer also liked the body design but did not like the body length, he thought the body was too long and would prefer something shorter. The criticism only grew when we presented our prototype because the prototype only validated the concerns of the customer.

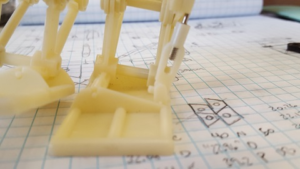

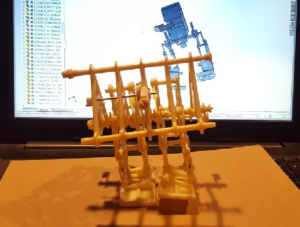

Fig. 10 – First prototype presented at CDR, the goal was to demonstrate static walking only.

The customer was not at all happy with our first prototype and gave us another week to present a second prototype. During the initial tests of this first prototype, we realized that the customer concerns were in fact right, the width of the Biped was too wide to be able to shift weight. We decided to scrap this design and work on something narrower. Figure 4 features the TJB toy with very narrow legs, the linkage design also incorporates weight shifting. Once again, I was under the gun to produce a new design in less than a week. Luckily we had in our possession, a TJB toy, and I was able to make all the measurements to create a design.

Version 4

Fig. 11 – Initial drawings of TJB crankshaft, lobe design, and spacing.

Fig. 12 – Leg design for Version 4/prototype 2 based on TJB toy.

Fig. 13 – Incomplete prototype 2 with TJB toy inspired legs.

For version 4 I decided to copy the TJB toy, literally. I measured all the linkages, created them on SolidWorks, and laser cut them on acrylic. Laser cutting turned out to be considerably faster than 3D printing and was ideal for prototyping. Although prototype 2 was still somewhat wide it was a start in the right direction because the Biped actually demonstrated balancing and something that resembled walking. To fix the width issue, we needed to source a shorter motor shaft. The current shaft was 6cm and we were able to find one that was 3cm. This new shorter shaft would allow the Biped legs to be closer together. We also had issues with the gear that was provided with the motor, because Theo Jansen linkages are specific dimensions, we needed to scale our linkages to match the size of that motor gear. We realized after the prototype was built and during prototype 2 demonstration the motor would stall because the gear would hit the leg linkages. Additionally, the servo in the ankle had to be scraped because the TJB toy has a very specific foot linkages that help shift weight, the servo between these linkages obstructed the motion necessary to shift weight.

Version 5

With the issues of version 4 resolved, I was able to move onto the body design. After doing extensive work with laser cutting, I figured it would be much faster to laser cut a body rather than 3D print. By laser cutting joints into the body pieces, I would be able to fit these together with little effort.

Fig. 14 – Sketches of what the body could look like. Featured are notches for easy assembly.

Based on CDR feedback, we knew the customer liked the body design which was inspired by the Star Wars ATST walker. We were not able to design arms that extended from the side of the Biped, the need for a narrow body restricted the amount of space available for additional servos. Instead I decided to house our external battery on a tray being held out by “arms”. These arms are laser cut on acrylic and the battery tray is screwed on to them.

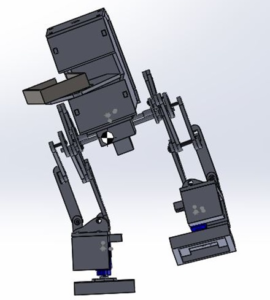

Fig. 15 – Final SolidWorks design of Biped featuring TJB legs, servo at the ankles, ATST body, and arms holding a battery tray.

Manufacturing went right up to the day of the final. Along with Alan Valles from E&C, we worked through the night to produce a walking Biped. While Alan uploaded and tested code, I routed, soldered, and managed wires. During the final presentation we played in Save the Human game in which Velociraptor Bipeds from other groups were to attack our human biped. Unfortunately, our Biped did not perform as expected. We did not have enough time to test the walking code with the balance code to produce stable walking.

Fig. 16 – Final Biped project as presented on the day of the final.

We were able to test the turning code which did produce turning. I believe if we had managed our time better we would have definitely produced a walking Biped.

Fig. 17 – Final design balancing on one foot to produce turning.

Conclusion

The design of this project was a long and grueling endeavor. Looking back, there are some things I would do differently. First, I would make sure to have clear expectations from the customer. When the customer is unsure of what he wants, the manufacturing engineer is expected to come up with a design that will wow the customer. This is a lose-lose situation because if such a design is reached then you are now on the hook for delivering every aspect of that design, and designs that wow are usually very intricate and complex. If such a design is not reached, then the customer is able to reject all designs, wasting value time in the process. This is even more important in a case like mine, where I had 8 weeks to do 16 weeks’ worth of work. Secondly, don’t allow others to influence your design unless you want them to. By allowing other people to influence your design you lose track of the wants of the customer. This doesn’t mean you shouldn’t seek for help, by getting someone else’s input you are able to attack a challenge in a different way. Although this was a tough project, it was very rewarding. Our leg design was by far the most complicated design out of all biped projects. The legs actually moved in a motion very similar to the TJB toy and when placed on a surface to walk, the Biped was able to walk with some human help for balance. If this group was together from the beginning of the semester, Biped would have walked and turned successfully on the day of the final.

Resources

[1] Solidworks