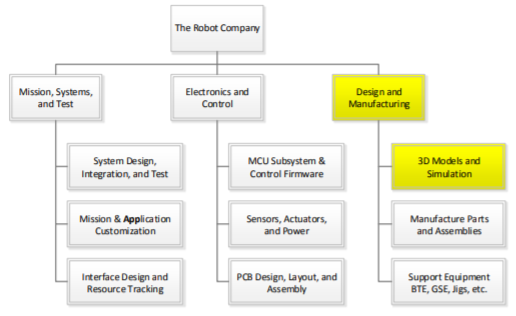

Design and Manufacturing Resources

Design and Manufacturing Resources Overview

3D Models and Simulation

Task Summary:

- Use CAD/CAE software to design the robot

- Use CAD/CAE software to design the mechanical parts

- Run static and dynamic simulations

The successful candidate(s) will use a solid modeling computer-aided design (CAD) and computer-aided engineering (CAE) software program, typically SolidWorks, to design the mechanical parts, subassemblies, and even the robot itself. The overall design must take into consideration all parts manufactured and purchased. The most commonly forgotten parts are the connectors and cabling.

Working with the systems engineer, determine the acceptability of the design by running simulations. These may be in the form of system-level animations (e.g., for bipedal robots the walking motion while tracking center of mass), system level load and shear analysis (e.g., for spiders a stress analysis across the body-servo-leg interfaces), and others as seen appropriate.

Qualifications

Work experience with a 3D modeling program or a desire to learn is a plus. Preferred modeling program is Solidworks; however, a working knowledge of Blender, AutoCAD, SketchUp or any other CAD/CAE program will be taken into consideration.

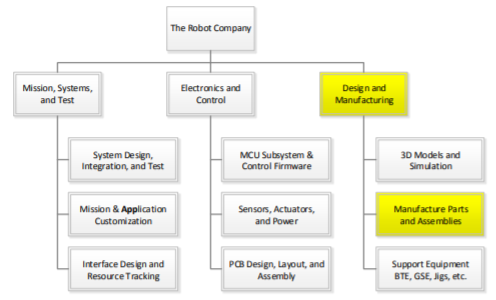

Manufacture Parts and Assemblies

Task Summary:

- Manufacture mechanical parts

- Become familiar with 3D printing process, operate 3D printer

- Learn to use the laser cutter

- Aid in physical PCB design

- Specify, source and order off-the-shelf parts

Parts may be fabricated using additive (3D printers), subtractive (CNC, laser cutter, lathe …), or other (vac-u-form, molds …) manufacturing techniques. It is important to work with the manufacturing Division Manager to find the manufacturing technology required for the project.

Off-the-Shelf Parts

Specify and order miscellaneous parts including:

a) Fasteners – nuts, bolts, screws, washers…

b) Adhesives and Sealants – tape, velcro, zip-ties, O-rings, weather stripping, silicone tube…

c) Powertrain Components – belts, gears, bearings…

d) Hardware – grommets, brackets…

The customer has a large number of fasteners, powertrain components, and other hardware. Otherwise, purchase such parts from Home Depot and McMaster-Carr among others

Case Study

The manufacturing engineer of a robot has a friend with a 3D printer. He asks his friend if she will print the parts for their robot. The friend agrees, assuming that the STL files will be provided within a few weeks.

Case 1: Near the end of the semester, the friend receives the STL files and realizes that they simply do not have time to print the parts. What should the manufacturing engineer have done to avoid this problem?

Case 2: The STL files are provided within a few weeks. However, the friend says her 3D printer is broken and she simply does not have time to fix it. Because the engineer now has time to recover from this disaster, instead of running around asking everyone if they have a 3D printer or purchasing time on a 3D printer, he contacts the Division Manager for help. The Division Manager bring up the problem at the next division meeting and another 3D printer is located. This is the strength of the matrix organization!

3D Printer

In the process of creating rapid prototyping designs and learning design constraints, the operation of a 3D printer is required. Learning the process of generating STL files, loading/managing a 3D printer and finishing 3D print surfaces is the task of the manufacturing division.

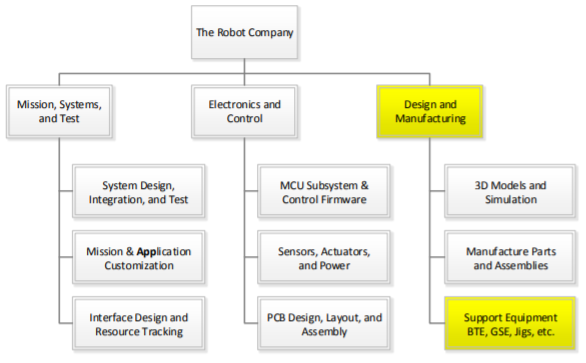

Support Equipment

Task Summary:

- Provide equipment support to project members

- Generate test equipment and locate necessary parts

During the design and development phase, E&C engineers will need to test electronics. The manufacturing engineer shall provide support in the design and fabrication of any Bench Test Equipment (BTE), Ground Support Equipment (GSE), and Test Jigs on an as needed basis.