Blogpost PCB requirement (L1-11)

Written by: Forrest Pino

Edited and Approved by: Carolina Barrera

Table of Contents

Intro:

In order to fulfill the L1-11 system requirement “Custom PCB” an analysis has been carried out. This test followed the Verification and Validation Test Plan. This requirement was one that applied to all the groups in EE 400D. It requires that groups develop a custom PCB that help the network and controller communication in the electronic system of the project.

Test Objective:

The test criteria that needs to be tested are provided by Prof. Hill in this class document[1]:

Prof. Hill provided multiple criteria which the Custom PCB should follow, and set a grade scale accordingly. For this project an “A”-Grade was desired.

Therefore this criteria apply:

“All components (resistors, capacitors, LEDs, IC chips) are surface mount. Some exceptions are header pins and large electrolytic capacitors, and components not available in surface mount. All PCB traces were manually routed. Used only one surface mount IC component for the PCB design. All other non-IC components were surface mount (resistors, capacitors. LEDs, IC chips). All PCB traces were manually routed.”[2]

Equipment

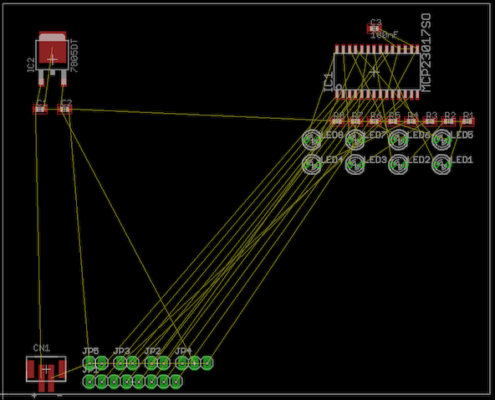

- Eagle Schematic and Layout

- Soldered Custom PCB

The PCB schematic and layout were designed using Eagle. Most of the ICs were ordered through Digi-Key. They are all surface mount components. Upon arrival of the PCB and the ICs, the components were tested to make sure there were no shorts or burnt components. Manufacturing solder the board by hand the first version of our PCB, but voltage outputs from the buck converter were not right. Chances are the board got burnt or one of the pins of the IC3 was not solder properly.

As a solution, Electronics and Control purchased a stencil, and the second version of the PCB worked perfectly. However, there was one feature that could not be implemented; the kill-switch. The incident is explained fully in the corresponding blog post, but the safety feature was removed from the system.

Conclusion:

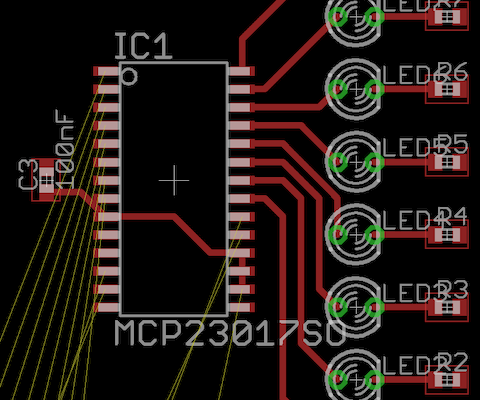

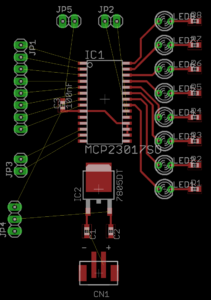

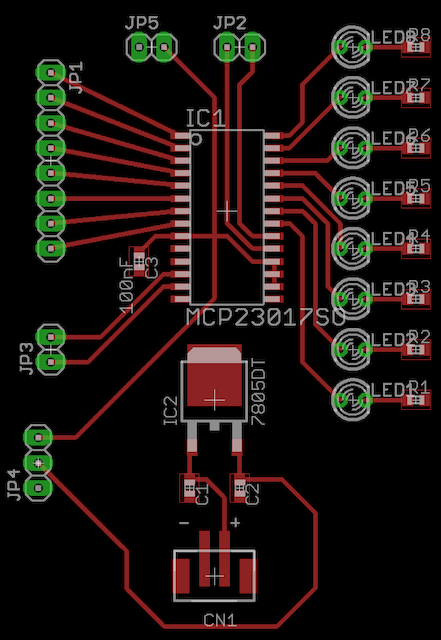

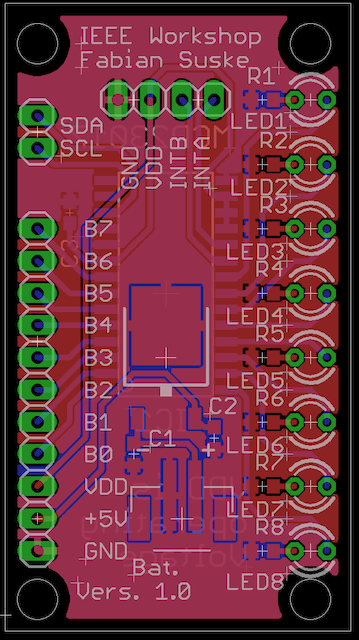

(Custom PCB) Showing all SMD components

On the Custom PCB are 2 Surface mount IC’s the Linear Technelogie LT3971-5 Buck Converter

(Showing the package of the Buck Converter)

as well as the Allegro A4988 stepper motor driver. The Buck is a DFN-10 Package. The motor driver is a QFN-28 package.

Both packages are a challenge to solder due to their small size.

The resistors and capacitors are all 0603. The Diode (DO-214AC) and the Inductor (1812) are bigger due to their availability.

Even the LDO is a Surface Mount Device. But this component is no challenge due to it’s big size (TO-263).

The connectors were implemented as PTH (Through hole) components.

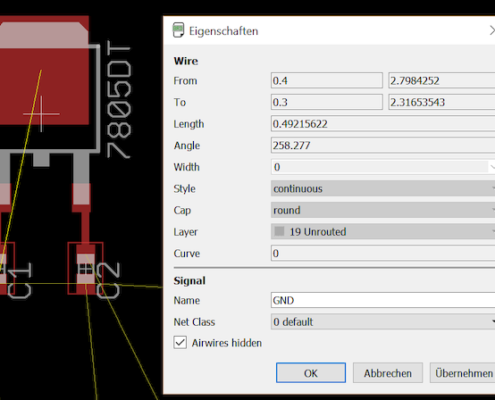

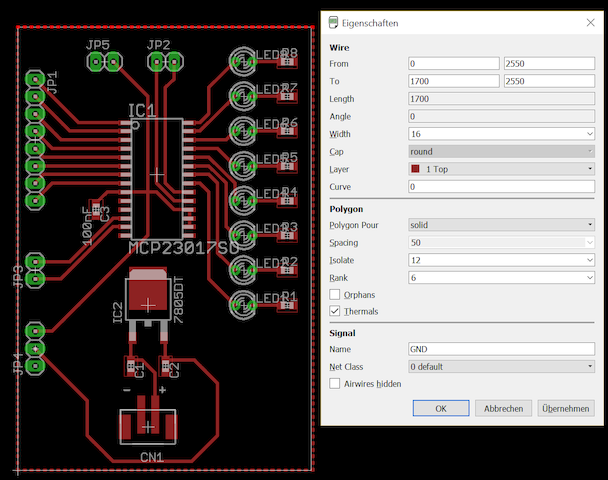

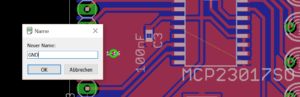

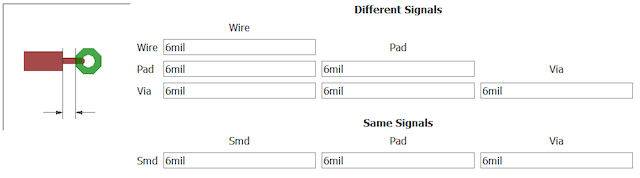

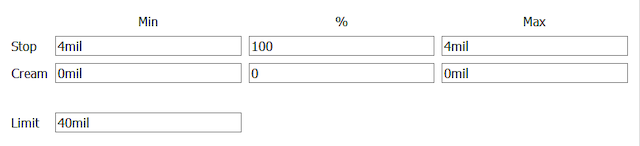

The traces were all manually routed following this instructions[3]

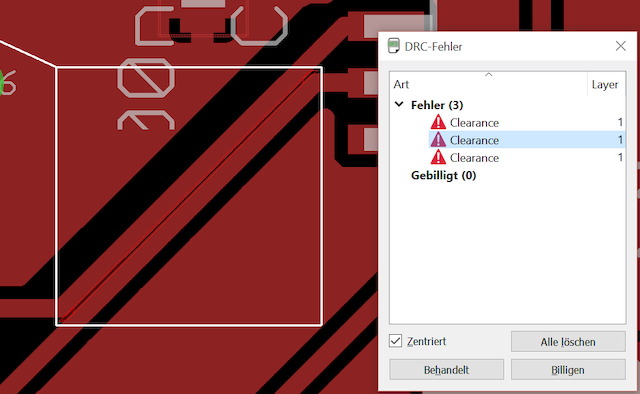

Afterwards the PCB was checked using a whole suit of DRC including OSH, Sparkfun and LeanPCB. The PCB passes every single one. Therefore the PCB passes this Analysis.

References

[1]http://web.csulb.edu/~hill/ee400d/Lectures/Week%2009%20Design%20Verification%20and%20Validation/a_Meeting%209%20Agenda%20F’16.pdf

[2]http://web.csulb.edu/~hill/ee400d/Lectures/Week%2009%20Design%20Verification%20and%20Validation/a_Meeting%209%20Agenda%20F’16.pdf

[3] http://arxterra.com/printed-circuit-board-pcb-how-to-layout/