By:

Carolina Barrera (Mission Objective, Creativity, WBS, Budget)

Luis Martinez ( Requirements, WBS, PBS)

Fabian Suske (Electronic and Control System)

Forrest Pino (Mechanical Design)

Hector Martinez(Mechanical Design).

MISSION OBJECTIVE (by Carolina Barrera, Project Manager)

Amputees are part of the aftermath in any warfare. When soldiers return from their mission with disabilities or missing one of their extremities, it is challenging for them to adapt to a new lifestyle. Technology has advanced far enough as to offer them an opportunity to get back to some of their previously regular activities using a prosthetic limb. In our specific case we have a soldier with a missing arm, and our mission – in conjunction with the Prosthetic Hand group in the other class, is to design and engineer a device that will help him/her perform an independent task as to eat a Quarter Pounder with Cheese meal by himself/herself.

To provide a better understanding to the reader and to avoid any confusion, a couple of definitions need to be provided at the beginning of this document. Hence, The Prosthetic Arm is defined as the device going from mid-bicep and continues down the arm until the point of integration with the Prosthetic Hand. The prosthetic Hand will be addressed as the device from the point of integration with the Prosthetic Arm down the metacarpals and including the fingertips. Finally, we will refer to the Upper-limb prosthetic system to the conjunction of the two projects, The Prosthetic Arm and The Prosthetic Hand.

CREATIVITY

All brainstorming and brainwriting ideas were done to come up with potential solutions for inconsistencies and possibly complications with the design. You can read on our approach and previous and future concerns in the following link:

https://drive.google.com/drive/u/0/folders/0B7_Bk0we7jCYS3R6SjBYOUYwVn

REQUIREMENTS:

LEVEL 1 PROGRAM/PROJECT REQUIREMENTS (by Carolina Barrera and Luis Martinez, Project Manager and Systems Engineer)

To satisfy the expectations of our customer, a team of engineers came up with a set of requirements from our end describing components and processes that are needed in order to excel in customer satisfaction at the delivery of our finalized product:

- The Prosthetic Arm shall operate together with the Prosthetic Hand to complete the mission, as components of the Upper-limb Prosthetic System.

- The Prosthetic Arm should have a range of motion localized at the elbow of (at least) + 60 degrees and – 90 degrees in the vertical axis, allowing the user to pick up individual food components of a meal, for consumption.(http://www.webmd.com/first-aid/bones-of-the-arm) and https://www.umc.edu/uploadedFiles/UMCedu/Content/Education/Schools/Medicine/Clinical_Science/Orthopedic_Surgery__Rehabilitation/Sports_Medicine/BiomechanicsoftheElbow.pdf

- The Prosthetic Arm shall have the capacity to operate for 20 minutes, based on the American average time per day spent statistics for “eating and drinking”. (http://www.bls.gov/news.release/atus.t02.htm Based on medium sized burger, fries, and drink components.)

- The Prosthetic Arm shall be able to lift the weight of the Prosthetic Hand and the weight of each individual McDonald’s Quarter Pounder with Cheese food item, in addition to its own weight. (http://calorielab.com/restaurants/mcdonalds/1 Estimated dividing by three meals per day, and rounding.)

- The Prosthetic Arm must be controlled by the soldier independently.

- The total cost of the Prosthetic Arm project shall be below $500.

- The project shall be completed by the end of Fall 2016- end of academic semester for the California State University, Long Beach.(https://web.csulb.edu/divisions/aa/calendars/documents/2016-2017AcademicCalendar.pdf)

- The Project shall fit in one of Professor’s Hill room cabinets, hence its maximum dimensions should be determined by the dimension of the cabinet.

LEVEL 2 SYSTEM/SUBSYSTEM REQUIREMENTS (by Luis Martinez, Systems Engineer)

L2-1 (Duration) The duration of the meal time permitted by the Prosthetic Arm shall begin upon the Prosthetic Arm first making contact with the selected food item from the McDonald’s Quarter Pounder with Cheese meal.

Explanation: To allow an amputee using the Prosthetic Arm 20 minutes of time to engage in consumption of a McDonald’s Quarter Pounder with Cheese meal, there must be a quantifiable start point for taking time, which is thus defined at the moment contact through the prosthetic is made with the respective meal component of choice.

L2-2 (Power Capacity) The battery system for the Prosthetic Arm shall have a minimum capacity of 1500 mAh.

Explanation: Based off an estimated current draw of 4.5A from the Prosthetic Hand and Prosthetic Arm power systems combined, a meal duration of 20 mins. yields a preliminary calculation for a 1500 mAh capacity requirement (http://www.powerstream.com/battery-capacity-calculations.htm)

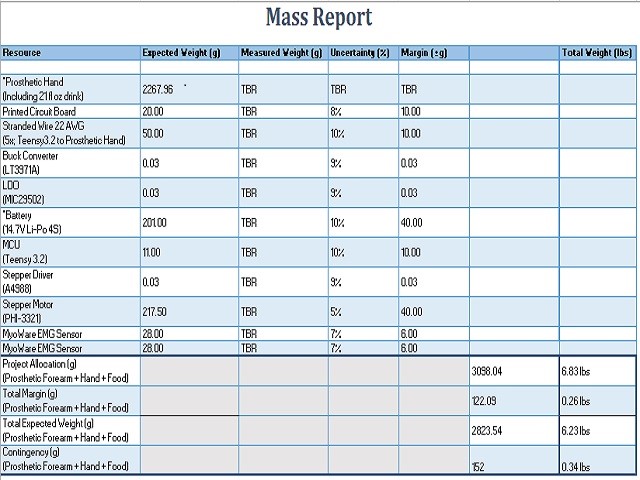

L2-3 (Weight Capacity): The Prosthetic Arm shall have the capacity to lift 5.49 lbs. ± 1.34 lbs.

Explanation: The Prosthetic Arm will be responsible for lifting the weight of the Prosthetic Hand, the weight of each individual food item from the McDonald’s Quarter Pounder with Cheese meal respectively, and its own forearm weight. Based on an average soldier’s combined forearm and hand weight of 3.8912 lbs. (men and women combined), calculated from average soldier weights and corresponding total body weight percentages for forearm and hand respectively, and the weight of the heaviest individual food item from the McDonald’s Quarter Pounder with Cheese meal (1.52917 lbs. for 21 fl oz Coca-Cola soft drink).

Drink Weight (21 fl oz): 1.5917 lbs. for Coca-Cola (1.3692 if water), derived from respective densities

Burger Weight (7 oz): 0.4375 lbs.

Fries Weight (4 oz.): 0.25 lbs.

Average Soldier Weight, Forearm + Hand (1.765 kg ± 0.61 kg): 3.8912 lbs. ± 1.34 lbs.

Weight Capacity = Heaviest Food Item (1.5917 lbs.) + Average Soldier Weight, Forearm + Hand (3.8912 lbs.) = 5.49 lbs. ± 1.34 lbs.

http://chemistry.elmhurst.edu/vchembook/121Adensitycoke.html

http://calorielab.com/restaurants/mcdonalds/1

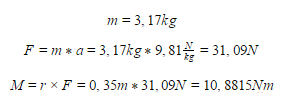

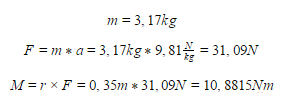

L2-4 (Torque) The motor for the Prosthetic Arm shall be rated for a minimum torque output of 10.634 Nm.

Explanation: Following a weight capacity requirement for 5.49 lbs. ± 1.34 lbs. (2.49 kg ± 0.6078 kg), and assuming an arm length of 14 in (35 cm), the torque requirement is estimated as follows:

L2-5 (Control) The Prosthetic Arm shall acquire input from sensors that detect bicep movement in the vertical plane.

Explanation: In order to achieve the mission objective of allowing an amputee with a prosthetic arm to eat a McDonald’s Quarter Pounder with Cheese meal, the arm must have the degree of freedom in the vertical plane (assuming the Earth’s surface as a reference X-Y plane). Following a L1 requirement for the arm to be controlled through biological signals, it is imperative that movement in the bicep be detected as this muscle allows movement in the defined vertical plane of interest.

BREAKDOWN STRUCTURE:

WORK BREAKDOWN STRUCTURE (by Carolina Barrera and Luis Martinez, Project Manager and Systems Engineer)

By the end of the Fall semester we should have completed a functional and somewhat polished prototype of a prosthetic arm. In order to meet our goal, we need to work and accomplish simpler tasks from smaller components, so that later in the semester these small parts can be integrated into the bigger, and more complex project. In other words, we need to break down the work into manageable sections so the subsystems can be working in parallel as much as possible. Figure 1 is the Work Breakdown Structure developed by Systems Engineer, Luis Martinez and Project Manager, Carolina Barrera.

Figure 2- Work Breakdown Structure Diagram

PRODUCT BREAKDOWN STRUCTURE (by Luis Martinez, Systems Engineer)

Similar to the WBS, there is the Product Breakdown Structure. The PBS breaks down the bigger components of the system into smaller pieces that can be built and tested in an initial phase of the project, and later integrated to other subsystems to come up with the overall system as a result. The Product Breakdown Structure is:

Figure 3 – Product Breakdown Structure

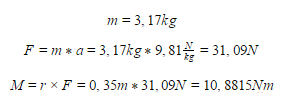

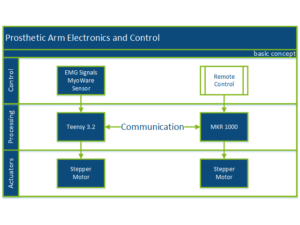

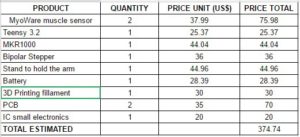

BUDGET

The estimated budget is presented below. We have omitted Ground Shipping and taxes because we are waiting on getting our material approved so we can buy them. For now, it would be wise to round up our number and we agreed on a margin of $100 in case of an accident and also in case we have to pay for 3D printing. This is how we came up with the budget of no more than $500 for the Robotic Arm project.

Table 1 – Estimated Budget (First Iteration)

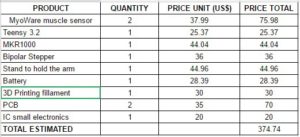

ELECTRONICS AND CONTROL SYSTEM (by Fabian Suske, Electronics and Control Engineer )

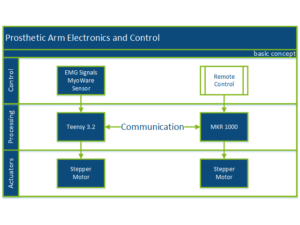

BASIC CONCEPT

A brief brainstorming about the prosthetic arm came to the conclusion that biomedical signals (bio signals) shall be used to control the arm. The two kinds of bio signals are EMG (Electromyography) and EEG (Electroencephalogram). The following research showed that both methods would be possible to implement. There are projects available which utilize each signals. But the hassle to get good EEG signals is much bigger then to get good EMG Signals.

Another aspect that came up in the brainstorming was the high precision needed to reach the target of feeding the soldier. Since servos were restricted to use. The focus led to stepper motors. Stepper motors are due to their mechanical construction very precise.

This ideas led to the following basic concept (figure 3):

Figure 3 – Basic Concept (Electronics)

EMG Signals are acquired by the MyoWare Sensor Shield. The signals are then send to the Teensy 3.2 MCU. There the signals are processed. The Teensy drives then the designated stepper motors. The motor for the “lifting” action is located above the elbow and is directly connected to the Teensy. The second motor used for radial movement is located below the elbow and is driven by the MKR 1000 MCU. This MCU has Wifi Capability onboard. This allows the system to be remote controlled (as a plan B). The MKR 1000 is also in charge of the power distribution (not included in this graphic). The two MCUs will communicate between each other.

References:

The project requirements state that a Quarter Pounder with Cheese meal shall be consumed. Based on this information we can measure the weight that has to be lifted.

Burger: 196 g.

Soda: 1.369 lbs.

Fries: 142 g.

The heaviest item is the soda with 1.369 lbs. The Hand subsystem stated that their subsystem shall not be heavier than 3 lbs. The weight of the arm itself shall not exceed ¾ lbs. With an allocated weight of 1 lbs. to the electronics the part of the system is around 6lbs. Since estimations were made a margin of 1 lbs is added. So the total adds up to 7lbs (3,17kg).

With an estimated length of the arm of 35cm (14 in) the motor has to deliver a torque of more then 10,8815 N

Therefore a motor with at least 10,888Nm is required.

Most stepper motors (in our budget) output a torque of 1.5-3NM. So a gear must be used to achieve the needed torque.

Since stepper motors operate at 12V and the MCUs run at less than 5Vs it is not possible to operate them directly of the MCU. Hence a stepper motor driver (stepper driver) must be used.

The stepper driver should be a Surface Mounted Device (SMD, SMT (Technology)). Also the motor should be controlled used with Step and Direction. This type is easy and simple and is sufficient. Therefore the Allegro A4988 stepper driver has been chosen. This driver operates on 3-5.5V and drives motors at 12 VTo limit the thermal output the driver will be operated at under 1 A Load Current.

Therefore the Phidget PHI-3321 stepper motor has been chosen. It operates at 12V and draws a maximum current of 670 mA

Figure 4 – Stepper Motor for the Elbow

The smaller motor used to rotate the wrist or elbow must still be TBD, but should require less current than the PHI 3321 since less torque is required.

Reference:

POWERTRAIN:

Since the Upper-limb Prosthetic System should work together as a system a common powertrain will be used. Since the space in the hand is limited the powertrain will be implemented in the prosthetic arm.

Based on the given requirements the powertrain can be dimensioned. The Hand needs up to 2.5A on 12V as well as up to 1A on 5V The MCUs operate at 3.3V but can be powered with 5V.

So the prosthetic System needs two Voltage Levels to power the System.

On the 12V level 700mA (peak) each for the steppers and 2.5A (peak) for the Hand sum to a total of 3,9A. On the 5V side the Hand requires 1A and the MCUs in the Arm need an estimated current of 200mA.

To provide 5V without a second power source a 12-5V buck converter will be used. This will add around 500mA to the 12V rail. So the 12V rail must provide 4,4A (peak).

Given this specification the Microchip MIC29502 LDO Voltage regulator has been chosen. This LDO has an enable pin so the 12V can be completely shut off. This provides some interesting efficiency features.

The fact that this LDO can be sampled for free is a plus.

To provide 5V 1A a buck converter will be used due to high efficiency compared to a LDO or fixed Voltage regulator. This also minimizes the head that will be dissipated.

The Linear Technologies LT3971A Buck Converter provides 1.3A continuous Current (up to 2A peak)

This Chip could also be sampled for free.

To power the 12V LDO 14,7V Li-Po Batteries will be used. Li-Pos are wildly available since they’re common in the RC market. 14.7V is the next higher available Voltage above 12V. A higher voltage is required by the LDO.

The size of the batteries has to be more than 1500mAh since the prosthetic system will drain around 4.5A and the time has to be 20 mins minimum. The size of the battery is TBD by the weight and volume that can be allocated to it.

References:

SENSOR:

The MyoWare EMG has been chosen to rapid prototype because it’s widely used.

The sensor operates between 2.9 and 5,7V and connects to an analog pin on the MCU. The input voltage will be outputted to the analog pin so if you supply it with 5V and connect it to an MCU that operates at 3.3V it will cause damage to it.

To achieve better results in distinguishing the different movements two or more sensors will be used.

Figure 5 – MyoWare Test with Arduino MKR1000

References:-

Figure 6 – System Block Diagram

Given this components the complete System Block diagram is shown in “Figure 3 System Block Diagram”.

The two MCUs are used to reduce the cable tree between the upper arm and the forearm. Since only Power and the I2C Interface must run between (instead of individual cables for the Sensors and Motors).

The Teensy MCU will be located in the upper arm since it is the smaller board. (In the upper arm is less space available.

The MKR 1000 with the Wi-Fi capability will be located in the forearm.

The I2C Interface will connect the two MCUs to allow communication.

References:

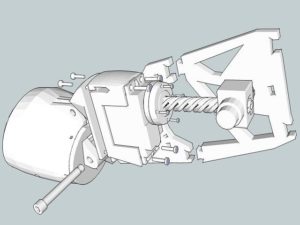

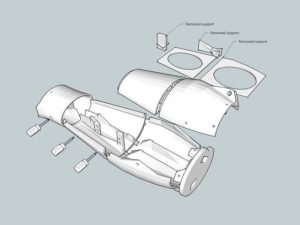

MECHANICAL DESIGN (by Forrest Pino, Manufacturing Engineer)

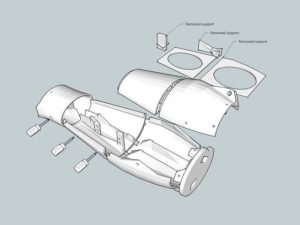

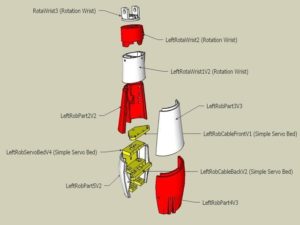

The prosthetic arm project will stem from multiple design ideas and will incorporate the key components that will make this project a success. The prosthetic arm project will utilize modified .stl files from the open source robotics project, InMoov, in order to satisfy the requirements. The provided forearm files will be edited in order to accommodate the robotic hand that will be attached to the prosthetic arm. The .stl files for the forearm will experience most of the modification and will mostly be a guide for the prosthetic arm. Fig. 7 was provided by the InMoov project site and shows the out layering of the forearm. The forearm coverings may be removed completely or modified in a way that shows the internal structure of the arm.

Figure 7 – Basic Design for the Prosthetic Arm

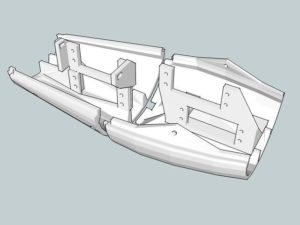

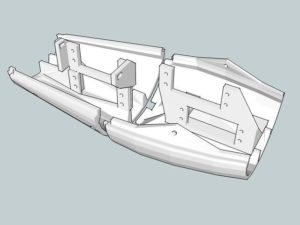

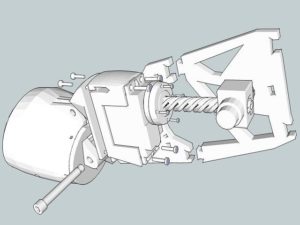

Figure 8 – Inside the Forearm Structure

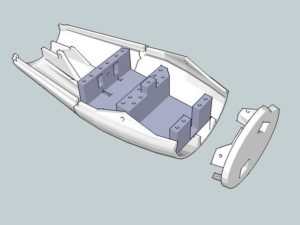

Figure 9 – Forearm and Elbow Assembly

Fig. 8 and Fig. 9 are internal housing designs provide by the InMoov open source project. The InMoov project made use of servos in the forearm while the prosthetic arm group will not be doing the same. The component housing structure for the InMoov design will most likely be removed.

The robotic hand project will not be utilizing the hand designs from the InMoov so integration between the two will be a custom design. The length of our forearm will also be determined by the specifications of the robotic hand. In order to counteract the weight of the arm, the forearm will be shortened as to not overload the DC motor with excessive leverage. One method of reducing weight will be editing .stl files so that less surface area will be printed and structural integrity will remain intact.

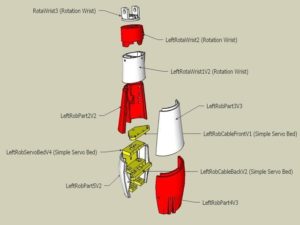

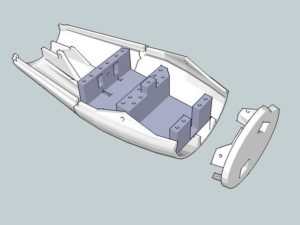

Figure 10 – InMoov design for Forearm

The InMoov site provided Fig. 10. The image shows and labels each part that was utilized in the InMoov design for the forearm. Since the forearm length may be reduced greatly, the only components that may be utilized will be the ones closest to the elbow. The Prosthetic Hand project will be in charge of creating the wrist so the components associated with the wrist in the InMoov design will be removed.

The methods of power and control for the prosthetic arm will differ greatly from the InMoov project. The degree of alteration means that the housing of the internal components will need to be custom. Depending on the size of the forearm, most of the components may need to be housed in the bicep of the prosthetic arm. The mechanism in the bicep that relates to extensions and contractions may not be suitable for our design and can be supplemented for system that utilizes a pulley. Utilizing a pulley could produce less friction than the InMoov design and would provide space for the PCB and other components. If a pulley were to be used, a mounting bracket would be needed for the motor. During research, an .stl file was acquired that would provide insight as to how mounting of the motor would be applied to the bicep.

Since an amputee will not be able to assist, a stand will be developed for testing and demoing. The current design will utilize PVC pipe and a hinge mechanism that will simulate shoulder movements. The stand will allow the prosthetic arm to hang in an orientation that would be similar to an amputee with a prosthetic arm. For demoing purposes, a member of the group will be able to guide the shoulder movements of the prosthetic arm while the other members demonstrate the effectiveness of the artificial limb.

Figure 11- Interconnection of the forearm and bicep

Figure 11 displays the interconnection of the forearm and bicep. The servos used in the InMoov design exceed the capabilities of the DC motor that will be utilized. This may lead to an alternate design that would provide movement to the forearm through a pulley system.

Refences:

SPECIAL ASSIGNMENTS AND DUE DATES: (by Hector Martinez, Manufacturing Engineer)

Design and Unique Task

- Meet with Prosthetic Hand to ensure proper mating of hand and arm(9/20/16)

- Analyze InMoov prosthetic arm design and look to modify and simplify for our mission objective (9/21/16-9/28/16)

- i.e. no need to house strings and motors in forearm based on preliminary Prosthetic Hand design(Instructables: TACT Low-cost, Advanced Prosthetic Hand).

- Modify InMoov heavy duty bicep design to fit our mission efficiently.

- Look into design modifications to lighten system weight (9/21/16 – 9/28/16)

- Trade-off study in materials (weight vs cost)

- Search for design techniques to reduce weight. i.e. cutting a pattern into the shell

- Study, analyze, and take apart existing prosthetic arm in ET-111 Lab (9/21/16-9/28/16)

- Look into cost effective design for a stand to hold prosthetic arm, as well as provide limited movement. (9/21/16-9/28/16)

- Study gearing, gear ratios, and gear options (9/21/16-9/28/16)

- Trade-off study between off the shelf gears and 3D printed

NOTE:

Our 2×2 picture was taken from:

http://inhabitat.com/inmoov-is-an-open-source-3d-printed-humanoid-robot/inmoov-3d-printed-printer-robot-open-source-gael-langevin-face/

Since our project structure is going to be based on the InMoov arm.