By: Brandon Perez (Missions, Systems, and Test Engineer)

Approved by: Ijya Karki (Project Manager)

Requirements 1st Draft

September 4th, 2016

Level 1

1.Shall be finished by the 9th of December, 2016 as designed in the CSULB calendar to correspond with the duration of the EE 400D class.

http://web.csulb.edu/~hill/ee400d/F’16%20Syllabus.pdf

2.Shall use a 3Dot board embedded system.

http://web.csulb.edu/~hill/ee400d/F’16%20Project%20Objectives%20and%20Mission%20Profile.pdf

3.Shall use one custom SMD I2C shield.

http://web.csulb.edu/~hill/ee400d/F’16%20Project%20Objectives%20and%20Mission%20Profile.pdf

4.The BiPed shall participate in an end of semester (December 9th, 2016) game where the BiPed’s goal is to outrun Velociraptor out of the arena with Goliath serving as its “eyes.”

http://web.csulb.edu/~hill/ee400d/F’16%20Project%20Objectives%20and%20Mission%20Profile.pdf

5.The BiPed shall use two DC motors to control walking movement of two legs. The choice of the DC motor will be compatible with the 3DOT board.

6.The BiPed shall walk statically and should demonstrate dynamic walking over flat, inclined, and declined surfaces for the entire duration of the game without falling over.

7.“Control of the walking robots will use the Arxterra Android or iPhone application operating in RC mode”

http://web.csulb.edu/~hill/ee400d/F’16%20Project%20Objectives%20and%20Mission%20Profile.pdf

8.The BiPed should be able to turn left and right at a maximum of 90 degrees at a time.

9.The BiPed should be able to maneuver around the arena and should avoid collisions with surrounding objects.

Level 2

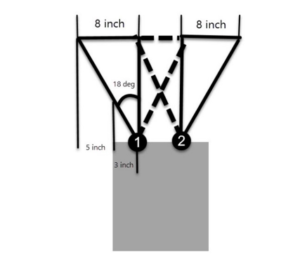

1.Should use four ultrasonic sensors to support the BiPed in preventing numerous collisions into surrounding objects. Refer to requirement 9, level

2.BiPed will have a Bluetooth v 4 .0 BLE Transceiver integrated circuit that will be able to communicate with the class website of Arxterra. Refer to requirement 7, level 1

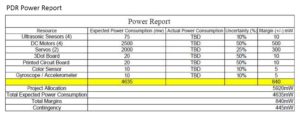

3.The 3Dot board shall be powered by a single CR123A 3.7V 650mA rechargeable Li-ion battery. A 9V battery will be used to amplify the 3Dot board’s signals. Refer to requirement 2 and 4, level 1.

4.The motors will receive their required voltage under operating conditions, as specified above, from the CR123A battery and the 9V battery.

5.The BiPed will use 2 DC motor to control its main walking motion. Refer to requirement 5, level 1.

6.The BiPed should use one wheel attached to one motor on each foot to execute the left and right turns. Refers to requirement 8, level

7.The I2C shield will utilize 4-pin connectors as well as a four-pin cable assembly to connect the four ultrasonic sensors via the I2C interface. Refer to requirement 3, level 1.

8.Biped should use a gyroscope as a sensor to determine its position with respect to the ground and shift center of mass in front of it or behind it when walking on inclined or declined surfaces respectively. The MPU-6050 (Gyroscope + accelerometer) should be used since it was implemented by previous BiPed projects and test software is readily available. Refer to requirement 6, level 1.

Requirements 2nd Draft

Oct. 10, 2016

Level 1 Requirements

1. Will be finished by the 9th of December, 2016 as designed in the CSULB calendar to correspond with the duration of the EE 400D class.

http://web.csulb.edu/~hill/ee400d/F’16%20Syllabus.pdf (Program Requirement)

Comment: Requirement left unchanged because it emphasizes a time-frame for our project.

2. Shall use 3Dot Board embedded system.

http://web.csulb.edu/~hill/ee400d/F’16%20Project%20Objectives%20and%20Mission%20Profile.pdf (Project Requirement)

Comment: Replaced word “one” to “a”. The previous requirement was forced to be quantitative.

3. Shall create a shield for the 3Dot board that utilize the I2C interference

http://web.csulb.edu/~hill/ee400d/F’16%20Project%20Objectives%20and%20Mission%20Profile.pdf (Project Requirement)

Comment: The new requirement is reworded for clarity.

4. Shall participate in an end of semester game where the Biped’s goal is to avoid contact with the Velociraptor. The Goliath team will be providing real-time video of the arena to the Biped group.

http://web.csulb.edu/~hill/ee400d/F’16%20Project%20Objectives%20and%20Mission%20Profile.pdf (Project Requirement)

Comment: Updated requirement provides a clearer description of the Mission Profile to the reader. Mission Profile needed to be restated in our requirements since it directly affects our overall system design.

5. Shall use a DC motor(s) to control its walking motion. (Project Requirement)

Comment: Removal of unnecessary information in the second sentence. The updated requirement emphasizes that each leg contains its own DC motor.

6. Shall be able to walk on flat, inclined, and declined surfaces of ± 6.5° angle measurement. (Level 2 Requirement)

Comment: Since the arena is described to be an environment with varying surface angles of ± 6.5° this requirement will now be serving as a Level 2 system requirement as a direct result of Level 1, Requirement 4.

7. “Control of the walking robots will use the Arxterra Android or Iphone application operating in RC mode”

http://web.csulb.edu/~hill/ee400d/F’16%20Project%20Objectives%20and%20Mission%20Profile.pdf (Project Requirement)

Comment: Requirement left unchanged since it is a project requirement from the customer for the teams to utilize the Arxterra Application for telemetry via Bluetooth to the 3Dot board.

8. The BiPed shall be able to turn left and right. (Level 2 Requirement)

Comment: The previous requirement stated a measurement of turning without any evaluation of why it had to be a maximum of 90° turns. This comment will now be utilized as a Level 2 system Requirement as a direct result of Level 1, Requirement 4.

9. This requirement will no longer be used. (Removed Requirement)

Comment: Removal of requirement because it is not a customer expectation or constraint.

10. Shall use a portable energy sources which should be capable of supplying power of a minimum duration of an hour. (Level 2 Requirement)

Comment: This requirement will be kept as a Level 1 Requirement since it emphasizes how long our system should be able to operate as a requested by the customer.

Level 2 Requirements

1. All sensors and actuators in our system shall be interfaced through the 3Dot board. Level 1, Req. 2

2. The 3Dot board only provides 2 DC motor drivers, and 2 servo drivers for direct component connection, therefore any sensors or additional actuators shall be controlled via an expandable 12C device addresser. Level 1, Req. 3

3. The Biped shall be walk, turn, detect pads on the floor, and operate for a minimum time frame of an hour in order to successfully compete in game designed by the game committee. The Goliath team shall require a proximity range from the Biped to provide video content for the Biped controller. The Arena in which the game will take place shall contain varying surface angles, therefore our Biped shall be able to walk on inclined and declined surfaces of ± 6.5°. Level 1, Req. 4

4. A DC Motor shall be allocated to control each leg to reduce the amount of torque applied if just one motor was being used. Level 1, Req. 5

5. Our Biped’s 3Dot board shall receive telemetry via Bluetooth communication with the Arxterra Application running on a group member’s Android device. Level 1, Req. 7

Requirements 3rd Draft

Oct. 16, 2016

Level 1 Requirements

The Biped Shall Statement:

1.Shall use a 3Dot Board embedded system.

2.Shall have a shield for the 3DOT board that will utilize the I2C interface.

3.Shall use DC motors to control its walking motion.

4.Shall be able to walk on inclines of (+/-) 6.5 degrees.

5.Shall be operated through Arxtrerra firmware via Bluetooth telemetry.

6.Shall be able to turn left and right.

7.Shall use a portable energy source capable of supplying power for an hour.

Level 2 Requirements

The Biped Shall Statement:

2.The system’s sensors and actuators shall interface through the 3Dot board. All system software shall be compiled onto the 3Dot board.

3.Arxterra firmware files shall be included in our software package for the 3Dot board.

4.An I2C interface shall be used to address additional devices for our system.

5.Two DC motors shall be used on our Biped to produce a walking motion.

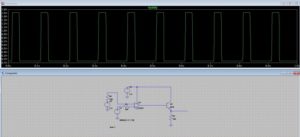

6.Shall use a shaft encoding system to help keep the leg movement system in sync with the weight shifting system.

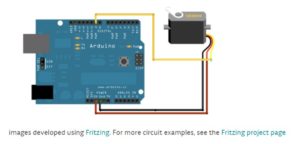

7.Servos on each of the Biped’s feet shall be implemented to produce turning.

8.Shall use a color sensor to detect floor pads in the playing arena.

9.Shall use a RGB LED to display the color of the pad that the color sensor has detected.

10.Shall use a servo to shift the system’s center of mass over from foot-to-foot.

11.Shall use accelerometer to detect when the Biped is on an incline or decline.

12.Shall use PID control method to keep the system balanced on inclines and declines.

13.Shall use a servo to shift the system’s center of mass when walking on inclined and declined surfaces.

Requirements 4th Draft

Nov. 6, 2016

Program Requirements:

1. The Biped shall be ready to participate in the game, “Save The Human”, proposed by the game committee on December 14th, 2016.

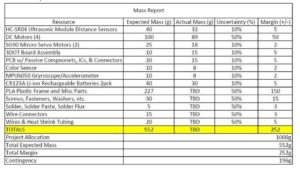

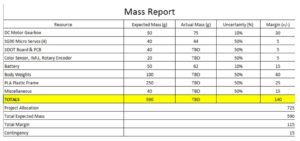

2. The Biped budget determined by the customer shall not exceed $125.00.

Project Level 1 Requirements

The Biped Shall Statement:

1. Shall use a 3Dot Board embedded system.

2. Shall have a shield for the 3DOT board that will utilize the I2C interface.

3. Shall use one DC motor to control its walking motion.

4. Shall be able to walk on inclines of (+/-) 6.5 degrees.

5. Shall be operated through the Arxtrerra control panel via Bluetooth commands.

6. Shall be able to turn left and right when commanded.

7. Shall use a portable energy source capable of supplying power for an hour.

8. Shall be able to detect power-up zones that will be present during the game.

Project Level 2 Requirements

The Biped Shall Statement:

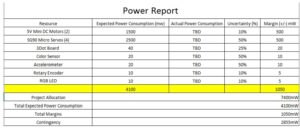

1. The Biped’s DC Motors and Servos shall have an operating voltage between 4.0 – 6.0V.

2. The Arxterra control panel shall be able send commands to the 3Dot and receive telemetry of the 3Dot board.

3. All external devices shall need to be 12C compatible or included onto an I2C GPIO expander.

4. Our choice of motor shall have a shaft output to both legs which shall be out-of-phase by 180°.

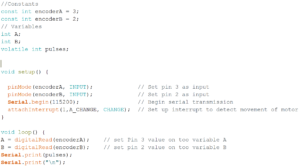

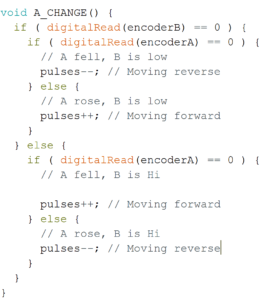

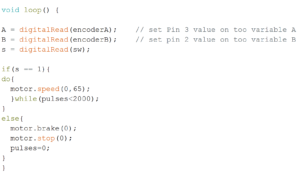

5. A rotary encoder shall be embedded onto the DC Motor shaft to provide data regarding the shaft’s position.

6. The servos acting as ankles on the Biped’s feet shall be able to turn the entire Biped’s mass of (TBD) while the Biped is standing on one foot. 7. Shall use a color sensor to detect color pads in the playing arena.

8. Shall use a RGB LED to display the color of the pad that the color sensor has detected.

9. Shall use a servo that produce a torque rating of at least (TBD) to raise the robot’s arms laterally.

10. Shall use accelerometer to measure the angle of incline the system is in when standing normal to the surface.

11. Shall use PID control method to keep the system balanced on inclines and declines.

12. Shall use a servo to correct the center of mass of the system when walking on inclined or declined surfaces.