Spring 2018 AT-ST Preliminary Model

By: Danny Pham (Manufacturing Engineer)

Verified By: Intiser Kabir (Project Manager)

Approved By: Miguel Garcia (Quality Assurance)

Table of Contents

Introduction

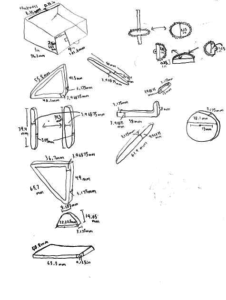

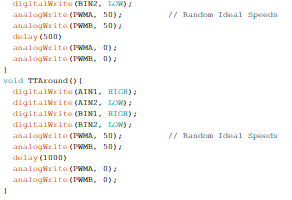

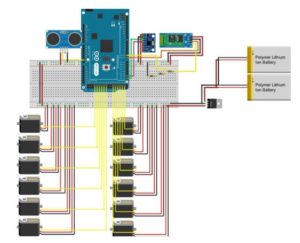

Our initial design included a similar concept to the Titrus III robot that involved moving the robot with servos. Since this was not ideal, we redesigned the legs to move using dc motor instead of servos and keeping the servo as a weight shift mechanism. Our design was inspired by previous velociraptor projects and an actual biped walking Theo Jansen kit.

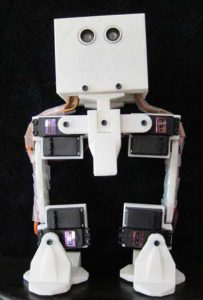

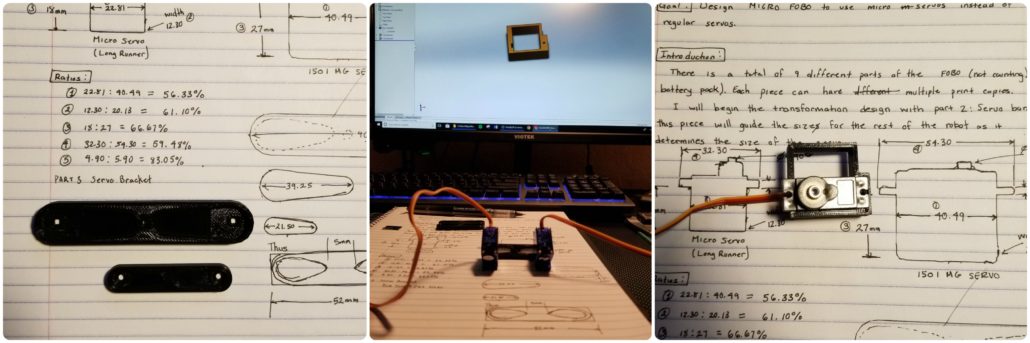

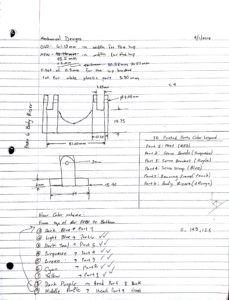

Initial Model

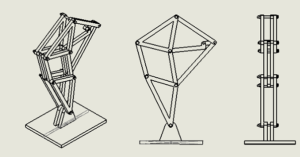

For our new design, we switched from a Titrus III leg design to the Theo Jansen design. We went with the Theo Jansen design because this design works much better when it is connected to a motor and the leg can rotate in a continuous motion.

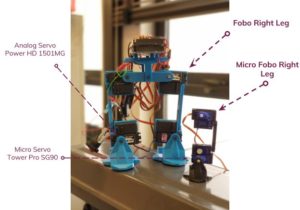

Description

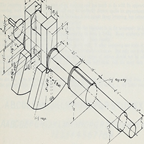

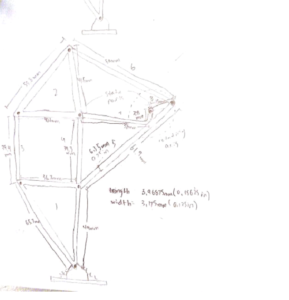

This is the Theo Jansen design. It incorporates a motor that rotates a gear that in turn rotates a shaft connected to the leg. This will rotate the rest of the leg and create a circular walking motion for the foot. This will allow the robot to take a step.

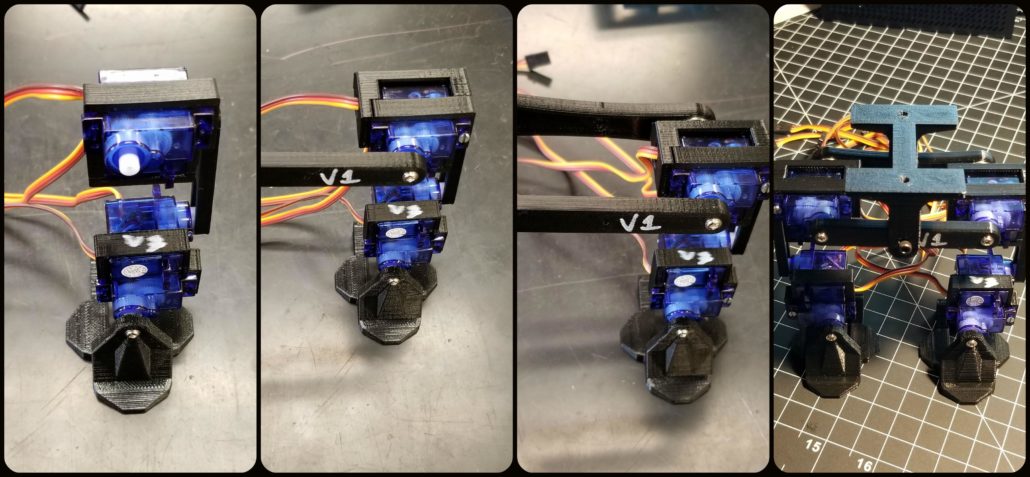

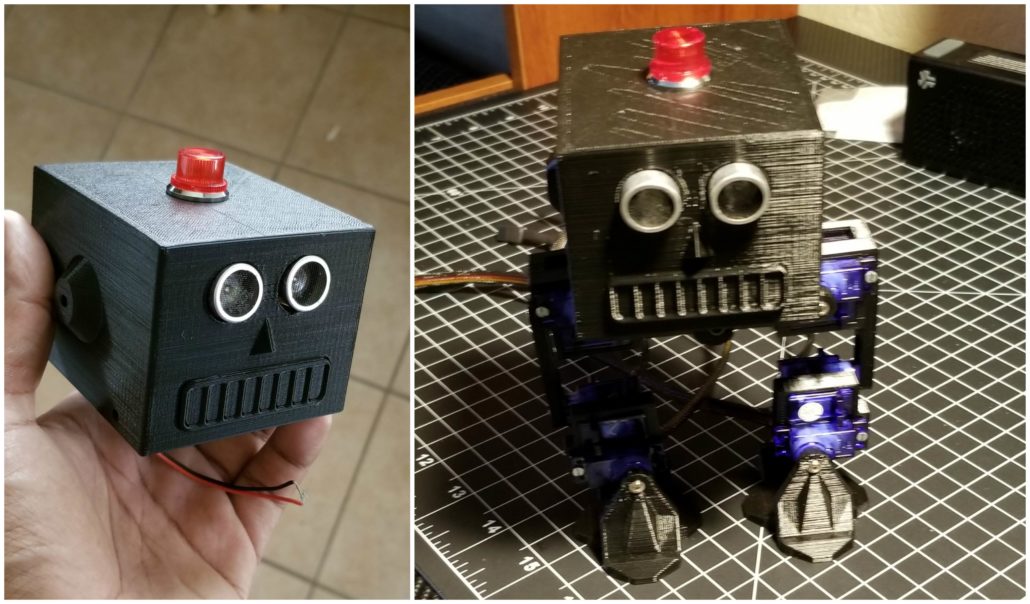

Description

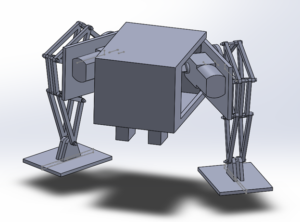

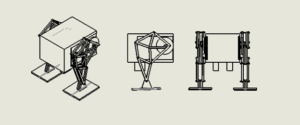

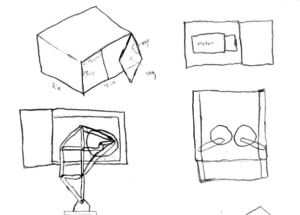

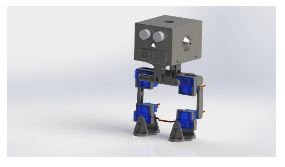

This is our first model that incorporated the Theo Jansen legs and split leg mechanism. I used a box for the body and implemented door hinges on the side that would act as the split leg mechanism that turns the legs. There are servos inside the box that are connected to these panels, and the servos would move the panel in and out to turn the legs. The DC motors are planted on the other side of the panels inside the box, and the motor is connected directly to the Theo Jansen leg. The motor rotates the leg and creates the walking motion for the robot.

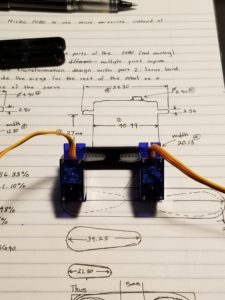

Issues with the model

Some issues with the model include the distance between the legs and center of mass. Because the legs are so far apart, it makes it much more difficult to balance the center of mass when the servos are turning the legs. If we had the legs closer, the weight is closer to the center instead of the sides and it will be easier to balance the robot. The box body takes too long to print and exceeds our requirement of six hours. Also, there are issues with the foot design, and how it plants itself on the ground when it is moving in circular motion. Because it is moving in a circular motion, the foot cannot be static or else it will not stay in parallel with the ground and that will cause points of contact that will conflict with the walking motion. The previous velociraptor group used springs in order to allow the foot to move in parallel with the ground, but it was not stable and made balancing the robot harder.

Conclusion

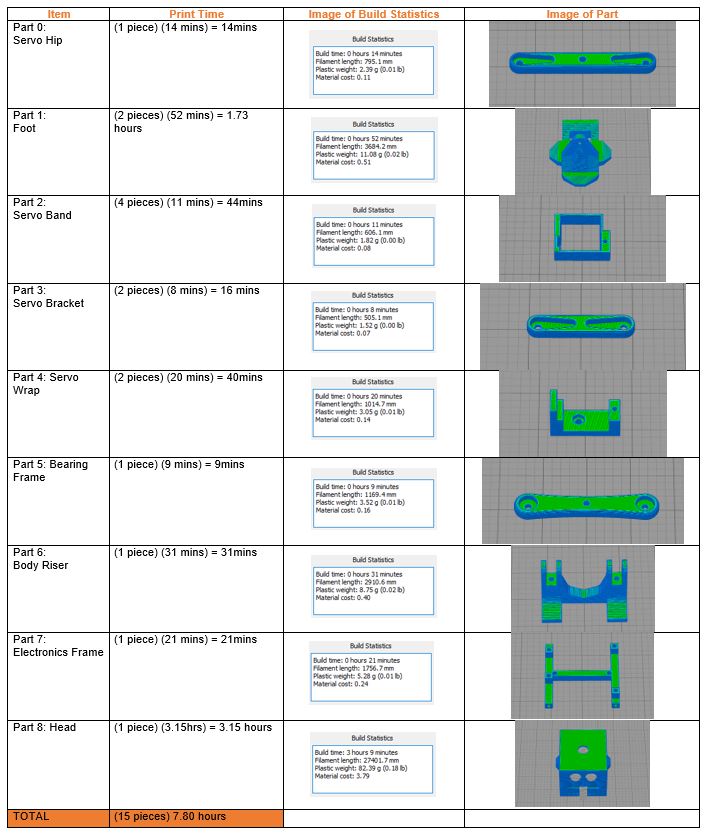

Our new design incorporates DC motors to move the legs. We will incorporate a weight shifting mechanism in the future with a servo so that we can do robot balancing during walk motion, but for now, the servos are used to turn the legs. A future modification of the design may include less distance between the legs so that we can balance it easier and a smaller mass for the body so that we can fulfill the print time requirement.