Spring 2016 Velociraptor: 3D Smoothing

By: Mingyu Seo (Manufacturing & Design)

Introduction:

In order to accommodate mass budget of the robot, our team has decided to create the legs and the top using 3D filament polylactic acid (PLA). One of the drawbacks of using 3D printing method is the result of the prints having ridged surface texture created by the layer by layer printing. There are multiple solutions for smoothing surface of PLA 3D prints to make the final product better. We will be looking at 2 methods that are safe and simple to apply.

3D printer setting:

Layer height (mm): 0.25

Shell thickness (mm): 1.2

Bottom/Top thickness (mm): 1.0

Fill Density (%): 25

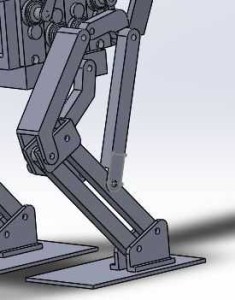

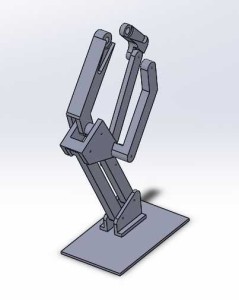

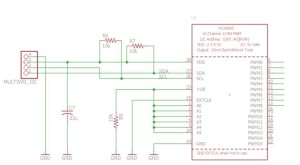

(Leg Picture here)

The picture shows the one of the finished print for the right leg, which we could clearly see the ridged surface texture.

Smoothing Methods:

- Acetone Bath

- Acetone bath is one of the most commonly used method to smooth out PLA and ABS materials. It melts the outer plastic and creates a smoother and glossy looking surface. Acetone bath is the simplest and fastest method to smoothing 3D materials.

Procedure:

- (Optional) Sand the 3D material using sandpaper (P320 most optimal) to smooth out the ridged surface.

- Pour enough acetone in a container (Just enough to fully submerge the part)

- Keep the part submerged for 40 ~ 60 seconds

- Take it out and dry.

(*CAUTION: make sure to use gloves when handling PLA due to melted plastic)

2. XTC-3D epoxy

- XTC-3D epoxy has lately been getting attention in 3D community which uses 2 liquids that are mixed together and then brushed onto 3D prints. Due to XTC-3D is a protective coating that does not melt plastic, so sanding all parts before applying is highly recommended.

Procedure:

- sand all surfaces of the 3D parts using P320 or P600 sandpaper.

- starting off with P600 may be a safer option,

- Apply coating on to 3D parts using a brush.

- Dry for minimum 4 hours.

XTC-3D coating works with all 3D materials as well as wood, plaster, fabric, cardboard, and paper. It’s easy to apply but takes a long time to dry. It takes minimum 4 hours and may need to be applied several times to have a unified smooth surface.

Conclusion:

To decrease production time, our team has decided to incorporate acetone bath to our final product. Program Level 1 Requirement 1 states the Velociraptor biped robot shall demonstrate its feasibility as a toy. To fulfill this requirement, acetone bath will not only help to smooth out the rigged surface but also improve the look of the final product.