| # Radius in cm of the tail

Radius = 10

LegRadius = 10

source(‘~/EE400d/Analysis/HeadandTailServoAnalysis.R’)

TailPositionX10 = TailPositionX

TailPositionY10 = TailPositionY

HeadPositionX10 = HeadPositionX

HeadPositionY10 = HeadPositionY

X_Moment10 = X_Moment

Y_Moment10 = Y_Moment

Radius10 = 10

LegRadius10 = 10

MaxTorqueHeadX10 = MaxTorqueHeadX

MaxTorquePlatform10 = MaxTorquePlatform

LegTorque10 = LegTorque

RealMaxLegTorque10 = RealMaxLegTorque

MaxTurningTorque10 = MaxTurningTorque

##

Radius = 9

LegRadius = 9

source(‘~/EE400d/Analysis/HeadandTailServoAnalysis.R’)

TailPositionX9 = TailPositionX

TailPositionY9 = TailPositionY

HeadPositionX9 = HeadPositionX

HeadPositionY9 = HeadPositionY

X_Moment9 = X_Moment

Y_Moment9 = Y_Moment

Radius9 = 9

LegRadius9 = 9

MaxTorqueHeadX9 = MaxTorqueHeadX

MaxTorquePlatform9 = MaxTorquePlatform

LegTorque9 = LegTorque

RealMaxLegTorque9 = RealMaxLegTorque

MaxTurningTorque9 = MaxTurningTorque

##

Radius = 8

LegRadius = 8

source(‘~/EE400d/Analysis/HeadandTailServoAnalysis.R’)

TailPositionX8 = TailPositionX

TailPositionY8 = TailPositionY

HeadPositionX8 = HeadPositionX

HeadPositionY8 = HeadPositionY

X_Moment8 = X_Moment

Y_Moment8 = Y_Moment

Radius8 = 8

LegRadius8 = 8

MaxTorqueHeadX8 = MaxTorqueHeadX

MaxTorquePlatform8 = MaxTorquePlatform

LegTorque8 = LegTorque

RealMaxLegTorque8 = RealMaxLegTorque

MaxTurningTorque8 = MaxTurningTorque

##

Radius = 7

LegRadius = 7

source(‘~/EE400d/Analysis/HeadandTailServoAnalysis.R’)

TailPositionX7 = TailPositionX

TailPositionY7 = TailPositionY

HeadPositionX7 = HeadPositionX

HeadPositionY7 = HeadPositionY

X_Moment7 = X_Moment

Y_Moment7 = Y_Moment

Radius7 = 7

LegRadius7 = 7

MaxTorqueHeadX7 = MaxTorqueHeadX

MaxTorquePlatform7 = MaxTorquePlatform

LegTorque7 = LegTorque

RealMaxLegTorque7 = RealMaxLegTorque

MaxTurningTorque7 = MaxTurningTorque

##

Radius = 6

LegRadius = 6

source(‘~/EE400d/Analysis/HeadandTailServoAnalysis.R’)

TailPositionX6 = TailPositionX

TailPositionY6 = TailPositionY

HeadPositionX6 = HeadPositionX

HeadPositionY6 = HeadPositionY

X_Moment6 = X_Moment

Y_Moment6 = Y_Moment

Radius6 = 6

LegRadius6 = 6

MaxTorqueHeadX6 = MaxTorqueHeadX

MaxTorquePlatform6 = MaxTorquePlatform

LegTorque6 = LegTorque

RealMaxLegTorque6 = RealMaxLegTorque

MaxTurningTorque6 = MaxTurningTorque

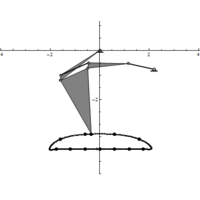

plot(X_Moment10,Y_Moment10, col = “green”, lwd = 5, xlab = “X Shift (cm)”, ylab = “Y Shift (cm)”, main = “CoG Shift By H/T Motion” )

lines(X_Moment9,Y_Moment9, col = “red” , lwd = 5)

lines(X_Moment8,Y_Moment8, col = “blue” , lwd = 5)

lines(X_Moment7,Y_Moment7, col = “cyan” , lwd = 5)

lines(X_Moment6,Y_Moment6, col = “purple” , lwd = 5)

legend(“topleft”, lty =c(1,1,1,1,1), lwd = c(1,1,1,1,1), col = c(“green”,”red”,”blue”,”cyan”,”purple”), legend = c(“R = 10cm”,”R = 9cm”,”R = 8cm”,”R = 7cm”,”R = 6cm”))

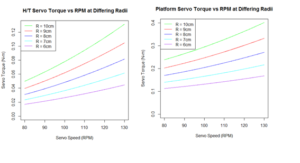

plot(MaxSpeed,2*MaxTorqueHeadX10, ylim = c(0,max(MaxTorqueHeadX10)), pch = “.”, col = “green”, xlab = “Servo Speed (RPM)”, ylab = “Servo Torque (N-m)”, main = ” H/T Servo Torque vs RPM at Differing Radii”)

lines(MaxSpeed,2*MaxTorqueHeadX9, pch = “.”, col = “red”)

lines(MaxSpeed,2*MaxTorqueHeadX8, pch = “.”, col = “blue”)

lines(MaxSpeed,2*MaxTorqueHeadX7, pch = “.”, col = “cyan”)

lines(MaxSpeed,2*MaxTorqueHeadX6, pch = “.”, col = “purple”)

legend(“topleft”, lty =c(1,1,1,1,1), lwd = c(1,1,1,1,1), col = c(“green”,”red”,”blue”,”cyan”,”purple”), legend = c(“R = 10cm”,”R = 9cm”,”R = 8cm”,”R = 7cm”,”R = 6cm”))

plot(MaxSpeed,MaxTorquePlatform10 , ylim = c(0,max(MaxTorquePlatform10)), pch = “.”, col = “green”, xlab = “Servo Speed (RPM)”, ylab = “Servo Torque (N-m)”, main = “Platform Servo Torque vs RPM at Differing Radii”)

lines(MaxSpeed,MaxTorquePlatform9, pch = “.”, col = “red”)

lines(MaxSpeed,MaxTorquePlatform8, pch = “.”, col = “blue”)

lines(MaxSpeed,MaxTorquePlatform7, pch = “.”, col = “cyan”)

lines(MaxSpeed,MaxTorquePlatform6, pch = “.”, col = “purple”)

legend(“topleft”, lty =c(1,1,1,1,1), lwd = c(1,1,1,1,1), col = c(“green”,”red”,”blue”,”cyan”,”purple”), legend = c(“R = 10cm”,”R = 9cm”,”R = 8cm”,”R = 7cm”,”R = 6cm”))

#plot(thetaLeg, LegTorque10 , ylim = c(min(LegTorque10),max(LegTorque10) + .1), pch = “.”, col = “green”, xlab = “Theta (Radians)”, ylab = “Motor Torque (N-m)”, main = “Leg Torque Versus Lever-Arm Angle”)

#lines(thetaLeg, rep(RealMaxLegTorque10, length(LegTorque)), col = “green”, lty = 2)

#lines(thetaLeg, LegTorque9 , ylim = c(min(LegTorque10),max(LegTorque9)), col = “red”)

#lines(thetaLeg, rep(RealMaxLegTorque9, length(LegTorque)), col = “red”, lty = 2)

#lines(thetaLeg, LegTorque8 , ylim = c(min(LegTorque8),max(LegTorque9)), col = “blue”)

#lines(thetaLeg, rep(RealMaxLegTorque8, length(LegTorque)), col = “blue”, lty = 2)

#lines(thetaLeg, LegTorque7 , ylim = c(min(LegTorque7),max(LegTorque9)), col = “cyan”)

#lines(thetaLeg, rep(RealMaxLegTorque7, length(LegTorque)), col = “cyan”, lty = 2)

#lines(thetaLeg, LegTorque6 , ylim = c(min(LegTorque6),max(LegTorque9)), col = “purple”)

#lines(thetaLeg, rep(RealMaxLegTorque6, length(LegTorque)), col = “purple”, lty = 2)

#legend(“topleft”, lty =c(1,1,1,1,1), lwd = c(1,1,1,1,1), col = c(“green”,”red”,”blue”,”cyan”,”purple”), legend = c(“R = 10cm”,”R = 9cm”,”R = 8cm”,”R = 7cm”,”R = 6cm”))

|