Spring 2017 Velociraptor: Fritzing Diagram

Table of Contents

Authors

By: Mohammar Mairena (Electronics & Control Engineer)

Approved By: Jesus Enriquez (Project Manager)

Introduction

Before one can create a custom printed circuit board (PCB), one has to create a Fritzing diagram. A Fritzing diagram is a virtual electronic circuit that is modeled after a circuit tested on the breadboard. Fritzing is used to provide the layout of the breadboard given the tools needed for a future PCB design.

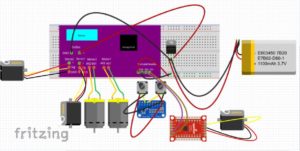

Fritzing Diagram

The diagram shown is the Fritzing diagram our group used for the Preliminary Design Review (PDR). The diagram is a very rough idea of the parts we are using for the final schematic. This diagram is meant to provide a general idea of the parts needed for the final PCB design. Each part shown serves a purpose.

The breadboard consists of the 3Dot board, three servo motors, two DC motors, an external battery, an A/D converter with rotary/shaft encoders, an additional low-dropout voltage regulator for the extra servo motor and a GPIO expander. Two DC motors are used to control the legs of the raptor, one servo motor to control the head and another to control the tail. The extra servo motor will be used to control the turning motion of the Velociraptor. Since the 3Dot board is only capable of utilizing two servo motors and two DC motors, a PWM expander is necessary for our additional servo motor. The PWM/Servo driver is not shown and should replace the GPIO expander in the design. The PWM/ Servo driver with i2C interface has the capacity to add extra servos through two pins, SDA & SCL (Data and Clock).

Note: The 3Dot board was taken from Fall 2016 Velociraptor’s fritzing diagram.

Resources

- http://web.csulb.edu/~hill/ee400d/Technical%20Training%20Series/07%20FritzingDocumentation.pdf

- https://www.arxterra.com/fall-2016-velociraptor-w-fritzing-diagram/