Fall Biped 2016- Updated Stall Current Motor Experiment

/in 3DoT Biped, Biped Generation #3/by ijya karkiBy: Alan Valles (Electronics and Control)

Approved by: Ijya Karki (Project Manager)

Table of Contents

Introduction

The Purpose of this experiment is to measure the stall current of the Pololu 1117 motor. This will be done in order to compare it to its rated value of 800mA.

Introduction

A stall current experiment was performed in order to see the actual stall current produced by Pololu 1117, this was done at the recommendation of Project Manager and ENC Division manager. Stall Current was measured utilizing two Pololu 1117 130 motors. The motors were set up in a mini vise as shown. Two small electrical loads were applied, one 100Ohm and One 1Ohm. The currents into the driving motor and out of the receiving motor were measured. As discussed in ENC meeting this should give us our stall current. The stall Current for the Pololu 1117 is rated at 800mA on the Pololu website.

The first run of test result in really low output currents to the motor load. However, this was due to the shafts losing grip of each other because the electrical tape overheated and began to lose grip of the two shafts. Thus, the receiving motor did not spin at a strong frequency with the other motor. The tape was redone and the experiment current increased by about 60%. Thus, the measured stall current would be around 492 mA. However, the measured current from inside a Tamiya gearbox was about 500mA so this value does not make sense. However, if another device could be used to tightly grip both motor shafts in order to better sync their frequencies than the number may have been closer to the rated 800mA. However, the rated 800mA was for 6v DC but the motor will be operating at 5V DC. As shown in the experiment. Taking the maximum motor value of 335 and multiplying by two we get, 670mA. This value is less than the rated 800mA rated stall current. One can figure that the actual stall current will be under the rated 800mA

| Electrical Load | Driving Motor Current | Load Motor Current |

| 100Ohm | 321 | 50 |

| 1Ohm | 335 | 100 |

| 1Ohm Redo | 328 | 164 |

Conclusion

In conclusion an experiment was done to measure the stall current of the Pololu 1117. The results were not definitive. However, using worst case analysis, the stall current of the Pololu 1117 motor can be seen as less than the 6v rating of 800mA since we will be operating at 5v.

Reference

[1] http://arxterra.com/pathfinder-motor-stall-current-test/

Fall Biped 2016- Project Manager- Managing

/in 3DoT Biped, Biped Generation #3/by ijya karkiTable of Contents

By: Ijya Karki (Project Manager)

Introduction

Project Manager Roles include certain tasks that must be completed, example:

- Defining WBS

- Level 1 Requirements

- Creating / Managing Schedule

- Creating / Managing Budget

- Final Project Video/ Documentation

There is a split of skills that a good project manager must possess, looking at the above list these skills can be differentiated with the words creating and managing. The easier of the two tasks include the creating. Documentation and guidance from the company CEO and President make creating a do-able process. The harder of the two skill sets is the managing portion.

Complications

What makes managing difficult? Managing can be difficult when one is working with their class mates and friends. There has to be a degree of authority established in the group so that there is an understanding that the Project Manager has the final says. This can become difficult when managing friends that one has spent years in class with.

Mistakes

From my communications class, I learned that these are typical issues that can arise when leading a group:

- Not establishing authority at all

- Failing to assign tasks

- Failing to follow up on task progression

- Failing to hold members accountable for failing to accomplish tasks

- Being too lenient on pushing the deadlines back

- Aggressively establishing authority

- Expressing the “I know more than you” attitude

- Assigning tasks with ridiculously unreasonable due dates

- Talking over members during meetings

- Passive Aggressively expressing feelings when members cannot accomplish tasks

- Taking out anger on members grades

- Being too friendly

- Letting anything slide by

- Neglecting due dates because they are trying too hard to make sure team likes them

Suggested approach

No one has perfecting good managing skills but these are suggestions and insights that can help one take a better approach than the mistakes listed above. Being PM doesn’t mean there is a choice that has to be made between friendship or PM roles. One can keep both tittles if they approach their responsibilities correctly.

- Don’t be afraid to assign tasks to teammates- In fact, as PM, one has to assign tasks to members. Although your teammates are smart enough to know what steps must be completed to successfully build your robot, it is still helpful to assign tasks and deadlines.

- During the old business portion of meeting minutes, ask for a progress about how far each member is coming with their tasks. They may need help and you can point them to the correct person that can help them. Or they might have forgotten about their tasks and the question will serve as a reminder.

- Let your members know that you will hold them accountable if they miss the deadline. Staying honest from the start is a better approach than giving off the vibe that it’s okay for the teammates to turn in material late but then taking points off from their grade. Keeping an open communication is important to finding the balance of managing. If your members know from the start that failing to meet deadlines has consequences, then they will not have a valid reason to be upset at their grade if they fail to complete tasks on time.

- Assign tasks with reasonable deadlines (depending on the task)

- Some tasks are ongoing processes (like coding or updating requirements)

- Set mini deadlines for various steps of the task

- Example 1: ask ENC to produce code for parts of your robot for various demonstrations that occur throughout the semester ( PDR, CDR)

- Example 2: If your systems engineer has to update the requirements, set mini deadlines for each draft (requirements continuously change throughout the year because they keep improving during each revision)

- If a member cannot meet a deadline for valid reason (tests in other classes, presentation in 400D that is of more priority) then it is alright to push the deadline back

- However, document in the meeting minutes the valid reason for changing the deadline

- Avoid getting in the habit of continuously changing deadlines

- One way to avoid this is by assigning tasks two weeks in advance so that you can check up on them and they have more than enough time to work on it

- Never assign last minute tasks (unless it is an emergencies)

- Your teammates have other classes they are also studying for and they will not appreciate last minute requests

- Do not blame members for failures

- A part of being PM means that you must keep the motivation and spirit of the group alive. If you have a negative attitude then that will affect the entire group.

- Singling a member out and blaming them for problems will not solve the issue. Instead, you can talk to them to see why they lacked in their part and understand what needs to be changed so that they will not run into the same problem with the next task that is assigned to them.

- Understand that you are a team. This means that no one can make a mistake alone. Although each member has individual tasks, the work you produce alone is collectively representative of the whole team. This means that one individual cannot be blamed for problems. Ultimately, the project manager is the most responsible individual for the group.

- When grading member, make sure to split up grades for each assignment into parts so that they can get points for all aspects of their work. Do not just assign a pass or fail grading system. Let them know that long as they try their best then their grade will match that.

- Example: Grading for meeting minutes can be broken down to different parts.

- The grade can be out of 10 points total.

- 5 points allocated to arrival time

- 5 for arriving on time

- 4 for arriving within 15 minutes past start time

- 3 for arriving within 30 minutes and past 15 minutes of start time

- 2 for arriving past 30 minutes of start time

- 1 for arriving past 60 minutes of start time

- 3 points allocated to participation

- 3 points for actively participating during the meeting

- 2 points for participating only during their part

- 1 point for

- 2 points allocated for completing the meeting minutes

- This way, the members will not lose points heavily for not taking meeting minutes one week if they are active participants of each meetings.

- Example: Grading for meeting minutes can be broken down to different parts.

Teammates that Lack Passion

In the event that a member in your group lacks passion, it is important to recognize these members from the start. The best solution can be to communicate with the member and figure out the reasoning behind why they are not committed and trying your best to motivate them. If that fails then you can converse with the Division manager to try and change or find a solution to the problem. Maybe your teammate wants to be in another group or there is a well skilled individual in another group that can help your teammate out. If all else fails, then communicate to the instructor the issue and the solutions you have already tried. Do not prolong this process, the further into the semester you go the more it will affect your grade if a teammate is unresponsive, uninterested, and idle. Be aware that if one of your teammates drop the course then you are responsible to complete both PM duties and the duties of the member that dropped.

Teammates that Lack Skill

In the event that a member in your group lacks skill, it is important to get them the help they need early on. Take initiative and talk to their division manager with a request that they spend more time on the material with your teammate or ask for a well skilled individual to be paired up to aid your teammate in their process. You want to avoid completing their tasks for them. If you get in the habit of finishing all of your teammate’s tasks, then you will have double the load and an idle member. The primary solution a skill lacking member should not be you taking over their job, but rather you directing them to their division manager for help.

Conclusion

| THE DOS | THE DONTS |

| Remain honest about grading | Don’t take out anger with grades |

| Assign assignments at least a week in advance | Don’t assign last minute assignments (unless an emergency occurs with the project) |

| Sit down with members and understand why they are struggling/figure out ways you can help them or direct them to the right person that can help | Don’t single out members and blame them |

| Assign members tasks and follow up on them | Don’t assume that members know what must be done and just wait for them to tell you what they completed |

| Keep grading scale fair by giving points to various parts of the project | Don’t be lenient with deadlines |

Fall 2016 Solar Panels: Creating a Port Expander Using IC MCP23017

/in Pathfinder Solar Panel/by Inna EchualBy Jose Rodriguez (Electronics & Control)

Approved By Inna Echual (Project Manager)

Objective: Because of our current design, a port expander is needed because there are no more available pins on our Arduino to read data from the reed switches. The reed switches will be used to halt the panels from cocooning more than it needs to; if it goes past a certain angle, it could hit the adjacent panel and damage its cells.

How to Set Up the IC

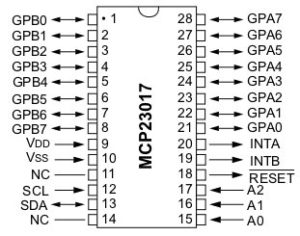

The Microchip MCP23017 is a 16-bit serial expander with I2C serial interface. This 28-pin IC offers sixteen inputs or outputs. Figure 1 shows the pinout data sheet for the IC:

Figure 1: MCP23017 Pinout [1]

Firstly, the expander was checked to see if it worked using two LEDs, which will be set high and low using the IC. Note that there are two banks, A and B, and each bank has a total of 8 pins. Both banks will be used in this blog to understand either or both of their activations.

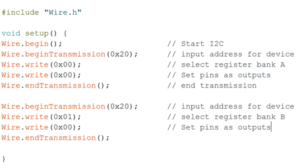

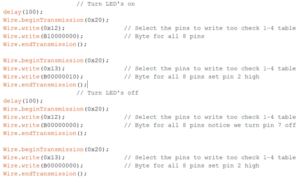

The code in Figure 2 is used to set up ports as outputs. The address for the device can be found on the data sheet [2], but to save time it is x20. To set pins as input, a one need to be set on the fourth column of the code depending on the required pin. Hex values are used, so for example, FF will set all pins as inputs. F0 sets the first 4 pins as inputs and the last 4 pins as outputs.

Figure 2: Code to Set Up Input and Output Ports

Once setup is complete, it becomes simple to set ports as high or low. The code in Figure 3 shows how to set up the pins using binary values. Four lines of code are needed to write on pins. The code takes a lot of space but there is a library that has been made for the MCP23017 by Adafruit that adds 1,000 bytes of memory.

Figure 3: Code to Set up Pins

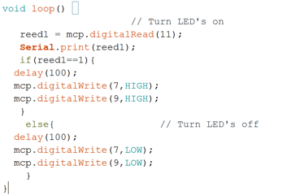

The Adafruit library needs to be downloaded and saved in the Arduino library because it can be used with the IC. The code for using the library is shown in Figure 4. First the Adafruit library has to be included by writing #include. The code from Adafruit is similar to that of the Arduino when it comes to setting up pins, but mcp. needs to be added before pinMode. The setup is straight forward however note that Bank b refers to pins 8 to 15.

Figure 4: Code to Use Adafruit Library

Alternatively, the following code in Figure 5 turns two led on and off, but is more efficient as it requires less code. Either method can be used but the latter is cleaner than the other. If memory code is an issue, then the longer method (firts code) will be optimal to save memory.

Figure 5: Alternative Code to Light LEDs

Conclusion

Adding a port expander is not as hard as one will think as using the Adafruit library makes the process even easier. To read a pin the command that will be needed is mcp.digitalRead only. The second method makes the code cleaner, but the first method gives an individual an idea of what is going on behind the second method.

References

[1] Maximising your Arduino’s I/O ports with MCP23017: http://tronixstuff.com/2011/08/26/tutorial-maximising-your-arduinos-io-ports/

[2] MCP23017 Data Sheet: http://ww1.microchip.com/downloads/en/DeviceDoc/21952b.pdf

Fall 2016 Solar Panels: Choosing Panel Thickness (Stress Tests)

/in Pathfinder Solar Panel/by Inna EchualBy Ridwan Maassarani (Design & Manufacturing)

Edited and Approved By Inna Echual (Project Manager)

Objective: The thickness of our panels must be carefully chosen as “too large” of a thickness could result in additional weight, possibly causing unnecessary strain and bending. Though the chassis could withstand our panels weight a maximum 50 lbs (as stated by the chassis group), we would like to chose a weight that would minimize bending as bending could cause our solar cells to break due to their delicate state.

Choosing Optimal Thickness

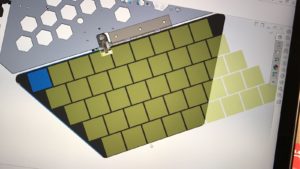

The thickness of the panels should be chosen so that it can carry its own weight under the force of gravity, as well as be well below the maximum 50 lbs. load requirement set by the chassis group. Cutting various panel configuration numerous times using varying aluminum thicknesses would take a long time and waste expensive material, the stress analysis tool feature in SolidWorks was used.

Figure 1: Panel Reference

The panel being evaluated is the butt panel (see Figure 1). The stress analysis tool was used on the butt panel to verify that it wouldn’t bend under the force of gravity.

The first step is to define a location where the object being tested will not move. In my case, it is three mounting holes for the hinge. Gravity acting on the top of the back panel was defined as the load. Using the mass properties tool under evaluate in SolidWorks, the approximate mass of the back panel was obtained to be 383.93 grams.

Note that the additional of the cells, rubber sheets, and glass will increase the weight; to remedy this, the weight of a single cell was measured and multiplied with the amount of cells that can fit onto the back panel.

Figure 2: Solar Cell Arrangement on Butt Panel

Currently, 33 cells can fit on the butt panel comfortably with 2mm spacing between them (also taking into account panel cutouts for the gears, see Figure 2 above). The weight of one cell was measured to be 0.75 grams so an approximate addition of 24.75 grams is added due to cells. Masses pertaining to the solder and copper tape is negligible but the cell system was rounded to 30 grams.

The total mass was converted to Newtons, which was entered into one of the SimulationXpress analysis wizard. Since aluminum was determined to be the material of our panels, it was selected in the design.

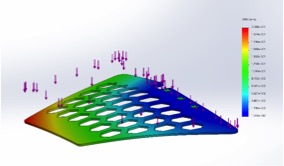

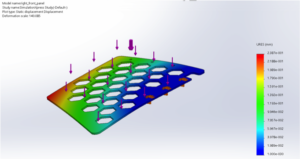

Figure 3: Butt Panel Displacement using 3.175mm Aluminum

Figure 3 shows the displacement acting on the panel. An eDrawing file can be saved once the results have been calculated. Furthermore, the tool can be used to optimize the design. For example, it allows the user to change dimension right and set goals to meet the customer’s needs. SolidWorks will calculate multiple scenarios to meet specific goals.

Table 1: Base to Butt Panel Deflection Data

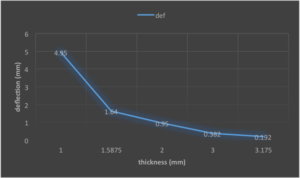

Graph 1: Thickness (mm) vs. Deflection (mm) of Butt Panel

Data concerning deflection was generated and inputted on Excel in order to determine panel thickness unacceptable deflection is seen. Table 1 shows the deflection from the base panel to the butt panel. The relationship between the varying thicknesses and resulting deflection is shown in Graph 1. The x-axis shows different thicknesses of 6061-T6 aluminum in millimeters and the y-axis represents the deflection distance in millimeters.

The four side panels (left front, left back, right front, right back) are similar in size and weight so the same stress analysis was done on the deflection between the base panel and the right front panel. Figure 4 shows the displacement acting on the aforementioned panel.

Figure 4: Right Front Panel Displacement using 3.175mm Aluminum

Figure 4 shows the deflection between the base and right front panel. Table 2 and Graph 2 contain the data on the relationship between thickness and deflection distance, as done with the butt panel.

Conclusion

Based on the data, we were able to determine that 1.25 in (3.175 mm) is the optimal thickness our aluminum should be to minimize bending. Our motors will be able to handle this weight and the total weight (including the addition of cells, wires, glass, motors, etc.) is still under the weight restriction of 50 lbs as set by the chassis group.

Fall 2016 Biped- Building the Game Arena

/in 3DoT Biped, Biped Generation #3/by ijya karkiTable of Contents

Building the Game Arena

By: Ijya Karki (Project Manager)

Introduction

As the semester comes to an end, it gets closer to testing the actual product. This is where the profile objective and the mission profile from the CDR is brought to life. The game, Save the Human, is played by four teams (Wednesday Velociraptpr, Thursday Velociraptor, Biped, and Goliath). The Game committee met on December 3rd, 2016 to finalize the game rules. Then, Ijya Karki, Fabian Suske, and Kristen Oduca built the arena pieces.

Biped Project Objectives

The project objective is to design a 6th generation toy Biped robot that will statically walk using two feet with the goal of dynamic walking.

The Biped will utilize the 3Dot Board

The Biped will partake in an end of semester game: Save The Human

The project must be completed by December 14th, 2016

The budget must stay under $125.00

Biped Mission Profile

Biped shall compete, alongside other toys such as Goliath and Velociraptors, in an end of semester approximately hour long game: Save the Human. Biped should successfully walk, using Goliath’s live video feed as the field of view, from the opposite end of the room to the finish area without coming into contact with a Velociraptor. The Biped will maneuver through multiple obstacles by turning through walls, sensing color pads, balancing on six degrees inclines/declines, and stepping through uneven terrain placed on top of Linoleum floors.

Finalizing rules

The First Step to building the game arena was to modify and finalize the rules that were proposed at the beginning of the semester. The original rules can be found under the Thursday Velociraptor blog posts: http://arxterra.com/fall-2016-game-save-the-human/

Suggested changes made:

- The incline angle should be 6.5 degrees allowing a ± 5 degree of handmade product production error.

- The Game arena should be at least 20% cardboard.

- The game arena (12 ft x 5 ft) shall be outlined with tape the day of the game.

- In the case that a robot steps out of the game arena, the robot will be disqualified from the game.

- Customer will have the power to place a few customizable pieces of the game including:

- Four 1 ft x 1 ft uneven square cardboard pieces

- Eight 6 in x 6 in uneven mini square cardboard pieces

- Three 6 in x 6 in colored construction paper power ups

Building the Arena

Step 1

Determining the sizes of various cardboard pieces.

To fulfill that the game would consist of at least 20 percent cardboard, we had to create a total of eleven 1 ft by 1 ft cardboard uneven pieces and two 3ft x 1 ft hills.

Arena size 12 ft x 5 ft –> 12 * 5 = 60 ft

60*20%= 12 ft (thus the game must have 12 ft of cardboard to satisfy 20%)

Total cardboard pieces are:

- Four 1 x 1 ft of uneven surfaces + eight 6 x 6 in of small uneven surfaces which results in=6 ft

- One 5 x 1 ft of rectangle uneven surface = 5 ft

- Two 3 x 1 ft hills = 6ft

Thus with 17 ft of cardboard used, the game committee successfully satisfied having building 20 % (12 ft) of the Arena with Cardboard.

Step 2

Purchasing the necessary parts

Cardboard, hot glue, and glue gun was purchased at home depot.

Step 3

Using box cutters, scissors and parts purchased at home depot, Ijya Karki, Kristen Oduca, and Fabian Suske build the necessary pieces to fill the arena.

Fall 2016 Velociraptor (W): Control Algorithm #1

/in Velociraptor (W), Velociraptor Generation #2/by LamNguyenBy: Taylor Farr (E&C)

Approved by Ryan Daly (Division Manager for Electronics and Controls)

Lam Nguyen (Project Manager)

Table of Contents

Fulfilled Requirements

- The Velociraptor shall statically walk.

- The Velociraptor should dynamically walk

In order to fulfill these requirements, a software algorithm needs to be implemented that reads the rotary sensors and move the dc motors and servos such that it is able to walk. Since the Velociraptor is using dc motors for the legs, rotary encoders need to be utilized so that the system knows the rpm and position of the motors at all times. No two dc motors are the same, so the pwm signal sent to the motors will vary for each otherwise the robot will be unable to walk. For our final design, we intend to use potentiometers for our rotary sensors.

Critical Design Review – Control Algorithm

Approach

For our CDR demonstration, we intended to use the potentiometers, however, this proved to be difficult to implement due to the size. Instead, we used optical sensors. The optical sensors behave like a switch. An led emits light while a BJT senses light. We then incorporated two circles with black ink across the diameter.

Materials

- 2 gm9’s (DC motors)

- 2 optical sensors

- 1 servo

- 3DoT Board

Control Algorithm – Summary

The algorithm is simple:

- Move the servo 30 degrees left (This will shift the head and tail over the left leg.).

- Move both dc motors 180 degrees (This will shift the right leg forward as the left leg moves and holds all the weight).

- Move the servo 60 degrees right (so the center of mass is over the right leg).

- Move both dc motors 180 degrees (This will shift the left leg forward as the right leg moves and holds all the weight).

- End

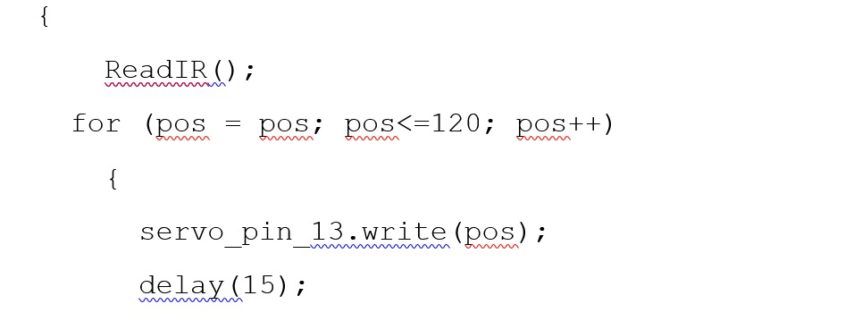

The algorithm uses a for loop to gradually move the servo to the desired position. Following that is a while loop. In the while loop, both motors move forward until the optoreflective switch reads a 0 output (An output of 1 indicates that the switch is looking at a white surface, and an output of 0 indicates the black line). There are two switches that need to be read, so some if statements are necessary in case one motor has moved 180 degrees before the other motor. After each sensor reads 0, each motor will stop. This will then use the for loop again to move the servo in the opposite direction. This subroutine is under moveHandler so that the systems engineer can use their Arxterra app to call the function using Bluetooth.

Figure 1 – Dc Motor with Optical Encoders

Control Algorithm – Code

void moveHandler (uint8_t cmd, uint8_t param[], uint8_t n)

{

ReadIR();

for (pos = pos; pos<=120; pos++)

{

servo_pin_13.write(pos);

delay(15);

SoftwareServo::refresh();

}

ReadIR();

motorA.go(param[0],0x40);// go(direction,pwm) –> direction: FORWARD =1, BACKWARD =2, BRAKE = 3, RELEASE = 4; pwm range(0-255) used to control the speed of the motor

//in my case I used 1 to move forward and a 255 for max speed

motorB.go(param[2],0x40);// go(direction,pwm) –> direction: FORWARD =1, BACKWARD =2, BRAKE = 3, RELEASE = 4; pwm range(0-255) used to control the speed of the motor

delay(500); // need to calculate delay

ReadIR();

// IR = digitalRead(sig);

//Serial.println(IR);

// IR2 = digitalRead(sig2);

while ((IR!=0)&&(IR2!=0))

{

motorA.go(param[0],0x40);// go(direction,pwm) –> direction: FORWARD =1, BACKWARD =2, BRAKE = 3, RELEASE = 4; pwm range(0-255) used to control the speed of the motor

//in my case I used 1 to move forward and a 255 for max speed

// IR = digitalRead(sig);

ReadIR();

motorB.go(param[2],0x40);// go(direction,pwm) –> direction: FORWARD =1, BACKWARD =2, BRAKE = 3, RELEASE = 4; pwm range(0-255) used to control the speed of the motor

// IR2 = digitalRead(sig2);

ReadIR();

}

if ((IR==0)&&(IR2!=0))

{

motorA.brake();

ReadIR();

while (IR2!=0)

{

motorB.go(param[2],0x40);// go(direction,pwm) –> direction: FORWARD =1, BACKWARD =2, BRAKE = 3, RELEASE = 4; pwm range(0-255) used to control the speed of the motor

// IR2 = digitalRead(sig2);

ReadIR();

}

if (IR2==0)

{

motorB.brake();

ReadIR();

}

}

if ((IR!=0)&&(IR2==0))

{

motorB.brake();

ReadIR();

while (IR!=0)

{

motorA.go(param[0],0x40);// go(direction,pwm) –> direction: FORWARD =1, BACKWARD =2, BRAKE = 3, RELEASE = 4; pwm range(0-255) used to control the speed of the motor

// IR = digitalRead(sig);

ReadIR();

}

if (IR==0)

{

motorA.brake();

ReadIR();

}

}

//IR = digitalRead(sig);

//IR2 = digitalRead(sig2);

ReadIR();

for (pos=pos; pos>=60; pos–)

{

servo_pin_13.write(pos);

delay(15);

SoftwareServo::refresh();

}

motorA.go(param[0],0x40);// go(direction,pwm) –> direction: FORWARD =1, BACKWARD =2, BRAKE = 3, RELEASE = 4; pwm range(0-255) used to control the speed of the motor

//in my case I used 1 to move forward and a 255 for max speed

motorB.go(param[2],0x40);// go(direction,pwm) –> direction: FORWARD =1, BACKWARD =2, BRAKE = 3, RELEASE = 4; pwm range(0-255) used to control the speed of the motor

delay(500); // need to calculate delay

// IR = digitalRead(sig);

// Serial.println(IR);

// IR2 = digitalRead(sig2);

ReadIR();

while ((IR!=0)&&(IR2!=0))

{

motorA.go(param[0],0x40);// go(direction,pwm) –> direction: FORWARD =1, BACKWARD =2, BRAKE = 3, RELEASE = 4; pwm range(0-255) used to control the speed of the motor

//in my case I used 1 to move forward and a 255 for max speed

// IR = digitalRead(sig);

ReadIR();

motorB.go(param[2],0x40);// go(direction,pwm) –> direction: FORWARD =1, BACKWARD =2, BRAKE = 3, RELEASE = 4; pwm range(0-255) used to control the speed of the motor

// IR2 = digitalRead(sig2);

ReadIR();

}

ReadIR();

if ((IR==0)&&(IR2!=0))

{

motorA.brake();

ReadIR();

while (IR2!=0)

{

motorB.go(param[2],0x40);// go(direction,pwm) –> direction: FORWARD =1, BACKWARD =2, BRAKE = 3, RELEASE = 4; pwm range(0-255) used to control the speed of the motor

// IR2 = digitalRead(sig2);

ReadIR();

}

if (IR2==0)

{

motorB.brake();

ReadIR();

}

}

if ((IR!=0)&&(IR2==0))

{

motorB.brake();

ReadIR();

while (IR!=0)

{

motorA.go(param[0],0x40);// go(direction,pwm) –> direction: FORWARD =1, BACKWARD =2, BRAKE = 3, RELEASE = 4; pwm range(0-255) used to control the speed of the motor

// IR = digitalRead(sig);

ReadIR();

}

if (IR==0)

{

motorA.brake();

ReadIR();

}

}

} // moveHandler

void ReadIR()

{

// Read in the ADC and convert it to a voltage:

int proximityADC = analogRead(QRD1114_PIN);

int proximityADC2 = analogRead(QRD1114_PIN2);

if (proximityADC < 630){

IR = HIGH;

}

else {

IR = LOW;

}

if (proximityADC2 < 630){

IR2 = HIGH;

}

else {

IR2 = LOW;

}

Conclusion

We were able to get the motors to move successfully. However, problems arose when we connected this to our prototype. There was more friction in the wheels than anticipated. Another issue is making sure that the legs start off in the correct position. If not, it is very likely that the robot will become unstable, and fall over.