By: Eduardo De La Cruz (Project Manager and Manufacturing Engineer)

Raymundo Lopez-Santiago (Mission, System, and Testing Engineer)

Kris Osuna (Electronics and Control Engineer)

Approved By: Miguel Garcia (Quality Assurance)

The purpose of this post is to provide helpful tips for the next generation of spiderbot based on our experience taking 400D. This post will be broken down into lessons learned by each division: Management, MST, E&C, and Manufacturing.

By: Eduardo De La Cruz

The goal of the project manager is to make sure the team finishes all tasks on the task matrix. The team will regularly depend on the project manager to get tasks published for feedback by the professor. If the project manager slacks off in posting a blog post, he/she will delay the teams progress. Making sure the professor is aware of all the things the team is doing is an important task of the project manager so make sure you know what each team member is regularly doing. If you are expecting not to meet project requirements make sure to let the professor know, as he will guide you to a solution, or just make you fill out a waiver for the requirement.

Mission, System, and Testing Engineer Remarks

By: Raymundo Lopez-Santiago

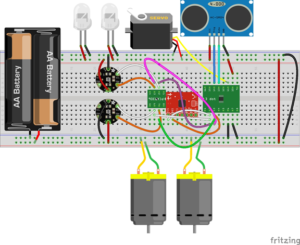

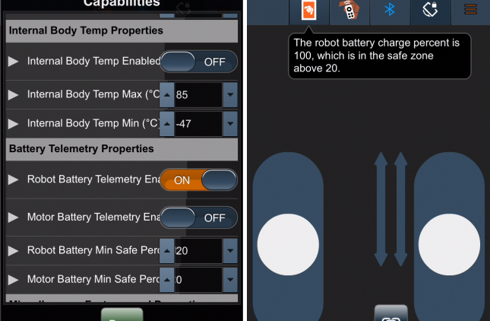

One issue identified in the system integration and assembly was the wire management and routing. As mentioned by the customer, the project should be designed from the cabling. Additional time should be spent on this section from the MST. As for testing peripherals, this should be done as soon as possible. One mistake on my part was starting late to do any testing on peripheral devices with the rest of team. For the verification document, I learned the hard way to not separate every requirement and make too many test cases. After meeting with the customer on a frequent basis, I went from 15 test cases to 8 test cases. One recommendation for future MSTs is to verify all requirements as soon as you can. Even if you do not have the 3DoT board in time, prototype with a sparkfun pro micro board. A heads up, order extra parts in case they stop working when testing is begun. Level 1 and Level 2 requirements were defined by the customer, but I recommend to meet with the customer to make sure the wording makes sense and that all system/subsystem requirements have a path back to high-level requirements. This will save you a lot of time when you are writing test cases. In my experience, all verification should be done at the Level 1 requirements. This is allowed since all system requirements lead back to Level 1 requirements.

Electronics & Control Engineer Remarks

By: Kris Osuna

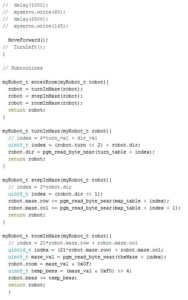

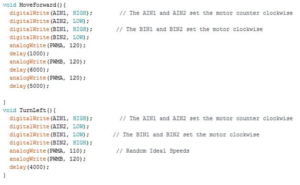

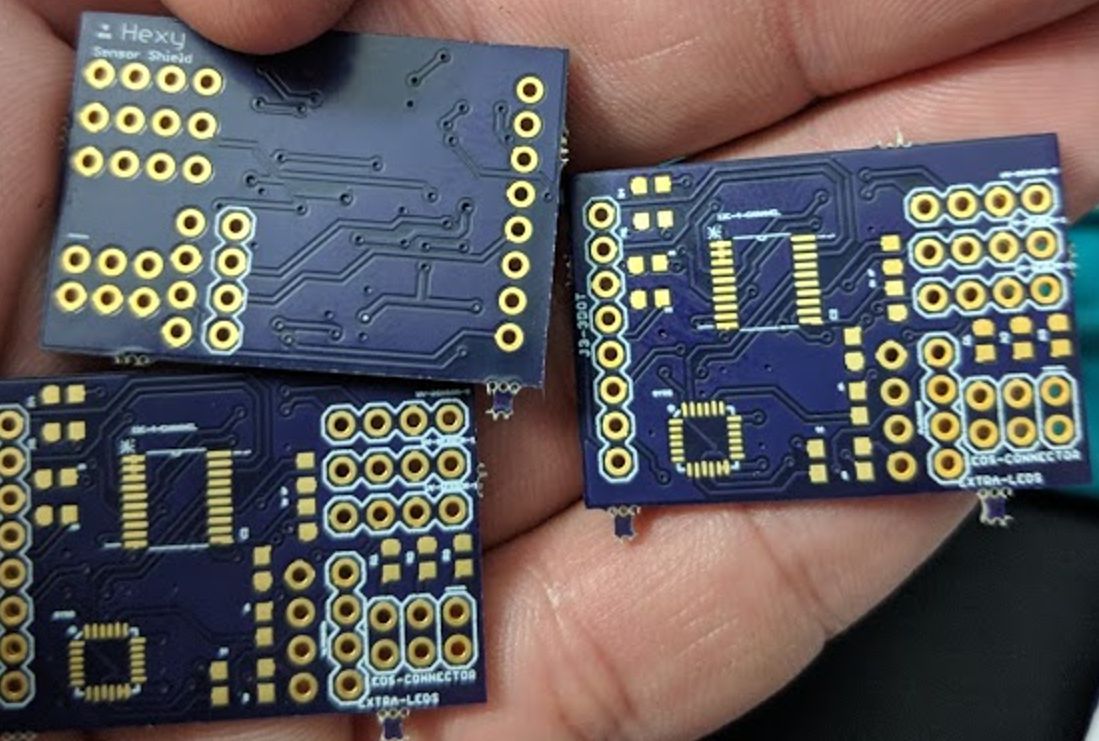

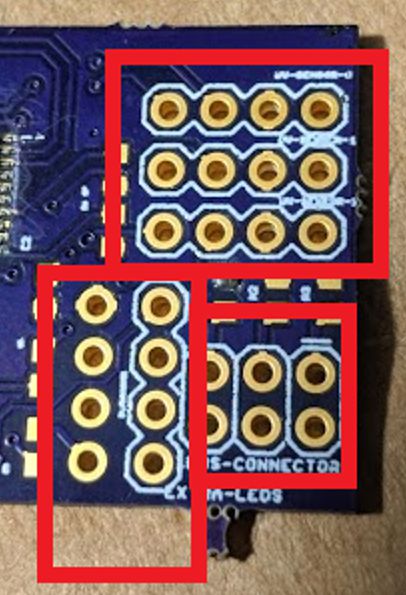

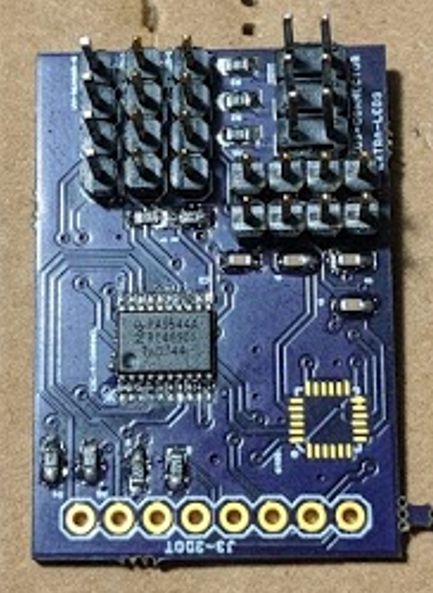

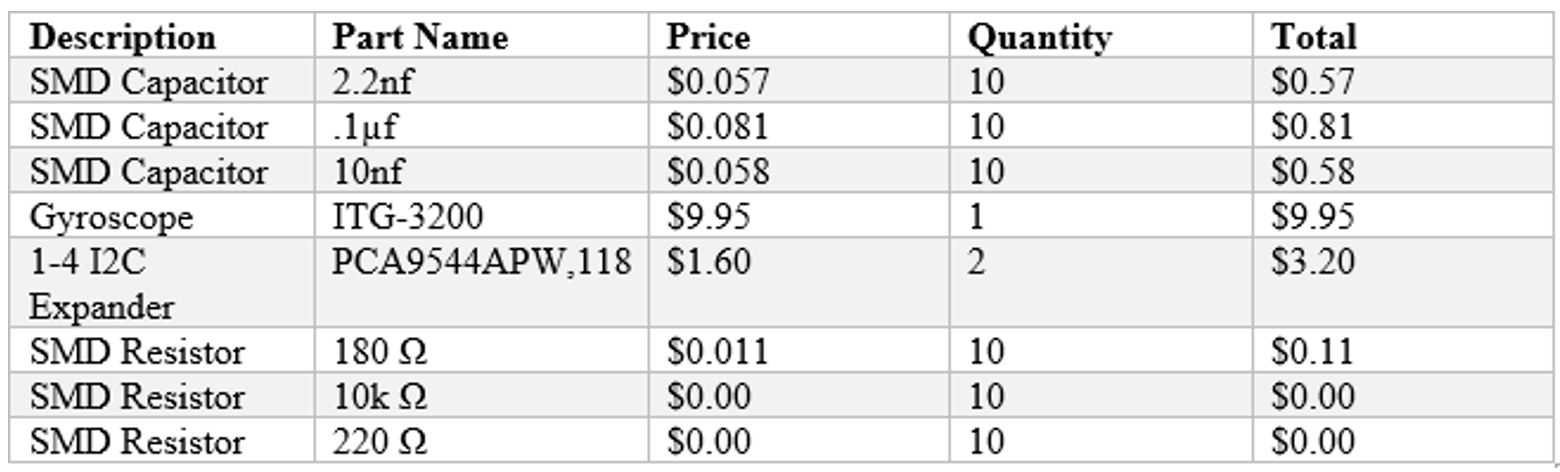

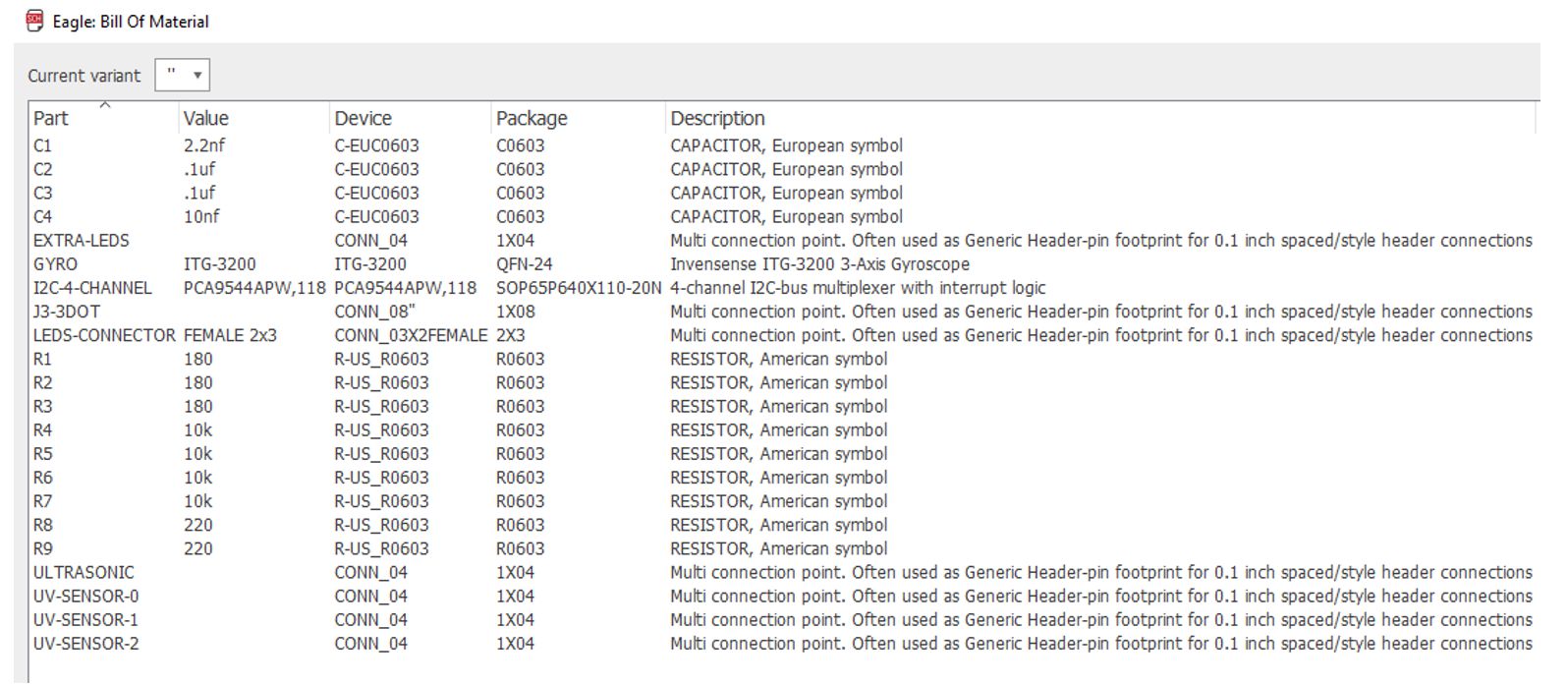

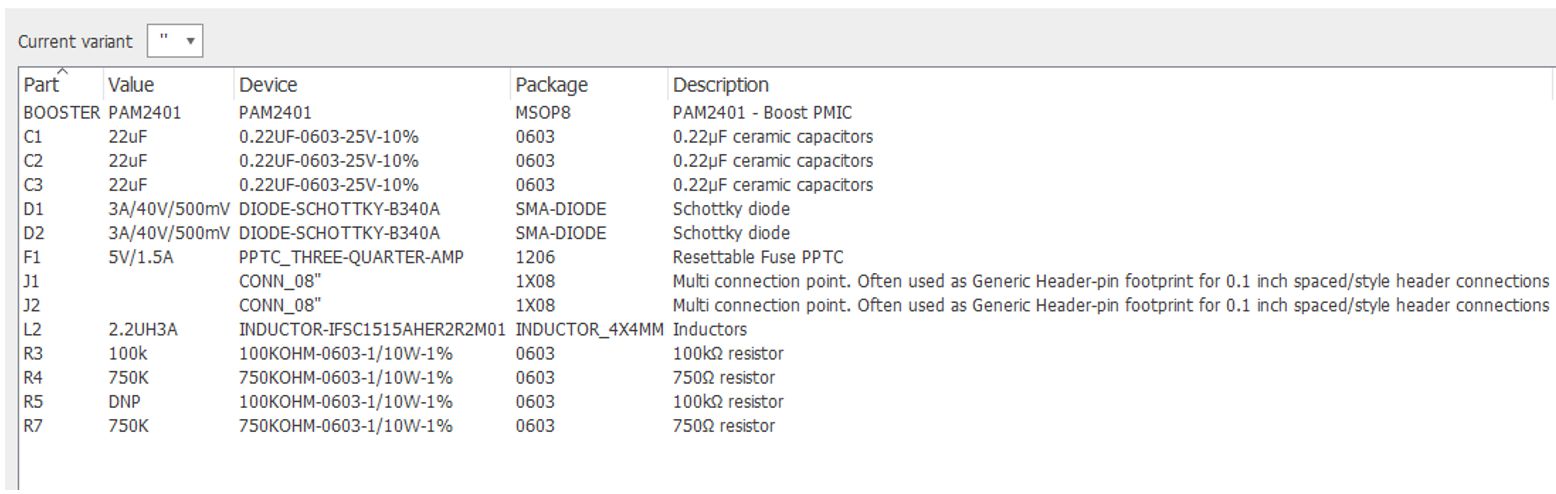

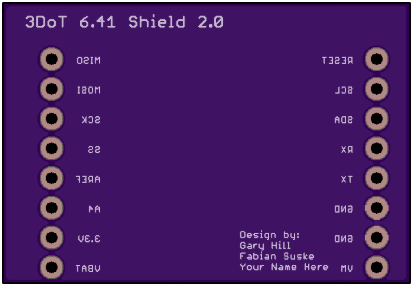

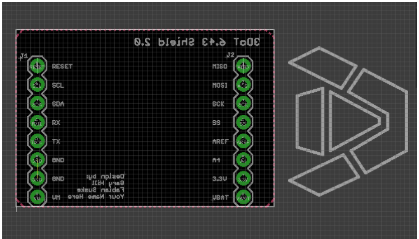

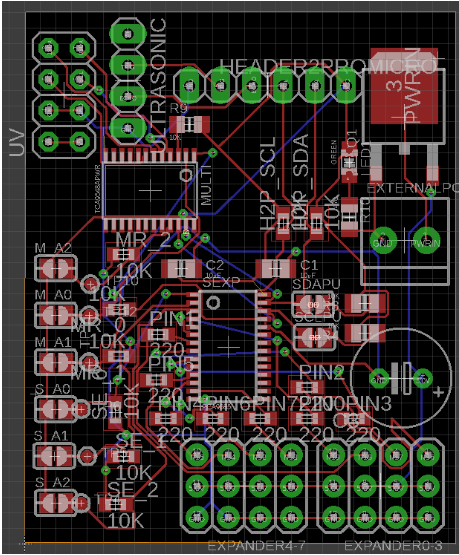

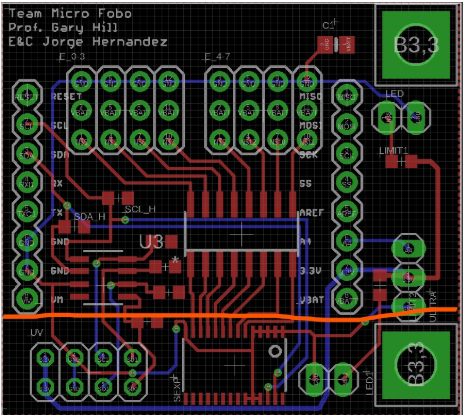

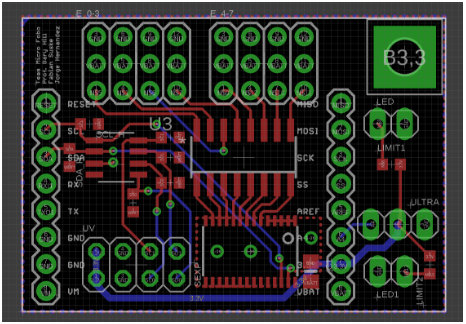

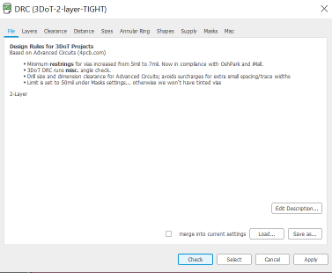

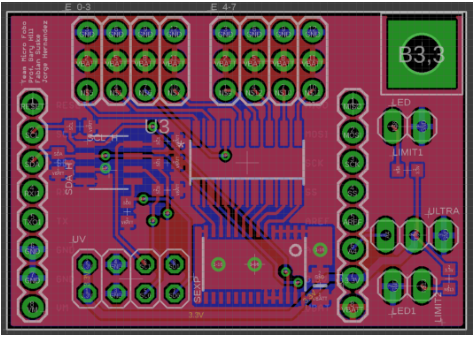

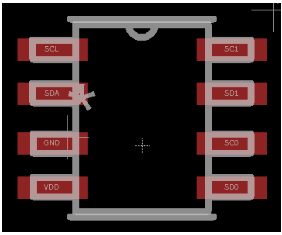

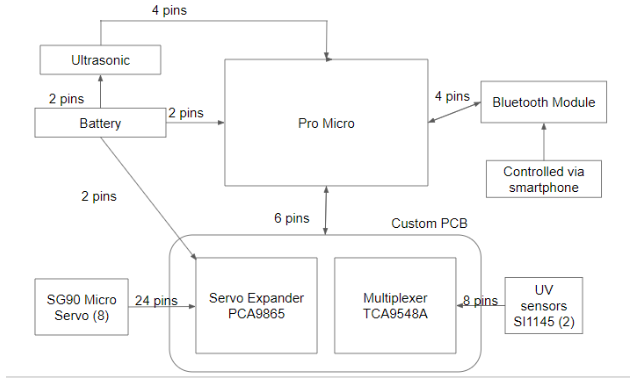

Getting familiar with Fritzing and EAGLE software is very important. Fritzing gives a visual for the end product. It shows you the pins you need and if the project is possible. I recommend working on the schematic and PCB as soon as possible. When making the schematic do not pick the first part you find in the EAGLE library. I highly suggest researching the part you are thinking about using. A mistake I made was not checking the availability of the integrated circuits I used in my schematic. The gyroscope I chose was three generations back and was unavailable in most places. The unavailability meant I could not purchase the item with the other components increasing the shipping costs and the overall cost of the project. I learned that when I finish the PCB the PCB is not done. The PCB goes through multiple levels of quality checks. If you turn in the PCB design on Monday you will get feedback and changes that need to be done, which will make your finished date Friday. Take into account corrections you might need and give yourself extra time for it. I suggest planning for redesigns and things that need to be fixed. Purchase extra pieces because things can go wrong.

Take pictures all the time. When doing blog posts I found that I was not taking enough photos to show the work being done. It is easier to show something than it is to describe something. Stay on top of your blog posts. Start your blog posts as you go along even if you do not finish because the event you are posting about just happened and it is harder to remember.

Manufacturing Engineer Remarks

By: Eduardo De La Cruz (Project Manager and Manufacturing Engineer)

Purchase a digital caliper if you do not have one already you will find it very useful throughout the semester. Learning SolidWorks as soon as possible is critical to getting things done in time. The Manufacturing Engineer should become competent in designing simple parts by the end of the first month and should be able to make more complex parts by the end of the second month. Review during every class meeting with the professor, a.k.a the customer, design changes or ideas as you will come to learn that sometimes the customer does not agree or like what you are making and will send you back to the drawing board. Sometimes groups would go weeks working on something only for the customer to dislike it and making them start over. Therefore, COMMUNICATION with the customer is critical to finishing things on schedule.

Getting acquainted with more than one 3D printing source will play to your advantage. The professor recommends his own 3D printing guy (Ridwan), however, far too often 3D prints would get delayed for days due to everyone reaching him around the same time. The manufacturing engineer should consider other 3D printing sources such as CSULB Makers group (located in VEC 518) or other off-campus printing shops.

When printing parts it is very important to consider how the part will be placed for printing. Like wood, 3D prints will have either vertical layers or horizontal layers based on the printing position. Sometimes moving parts will require you to pick a specific printing position in order to prevent layer splitting, or if you are considering inserting threaded screws into the material. If the layering is perpendicular to the angle at which the screw is being inserted you will most likely split the printing material as you insert the screw. Click here to read more about layering and print positioning.

Print positioning is also very important when it comes to parts that will be elevated off the ground at an angle greater than 45 degrees. Areas that will be off the ground will require print support in order to prevent sagging. Adding support decreases the print quality, as well as increases 3D print times. Click here to read more about this.

Finally, when talking to your 3D printing supplier, it is important to understand the role layer height plays in determining the quality and cost of the print. The thickness of each layer determines the resolution of the print. The smaller the layer height the smoother the print. However, as layer height decreases the longer the print and the higher the cost. Usually for prototyping, since time is critical to meet the 2-2-2 print requirement, layer height might be set around .3 mm for quicker production, whereas for final prints layer height could be less than .1mm since time is not an issue. Click here to read about layer heights.

References

- https://www.3dhubs.com/knowledge-base/how-does-part-orientation-affect-3d-print

- https://www.3dhubs.com/knowledge-base/supports-3d-printing-technology-overview

- https://support.formlabs.com/hc/en-us/articles/115000015870-When-to-Use-Different-Layer-Heights