Spring 2017 End of Semester Game “Pacman”

By: Alexander Clavel

Apporved By: Game Committee

Table of Contents

Game Committee Members:

Amber Scardina – TRC President

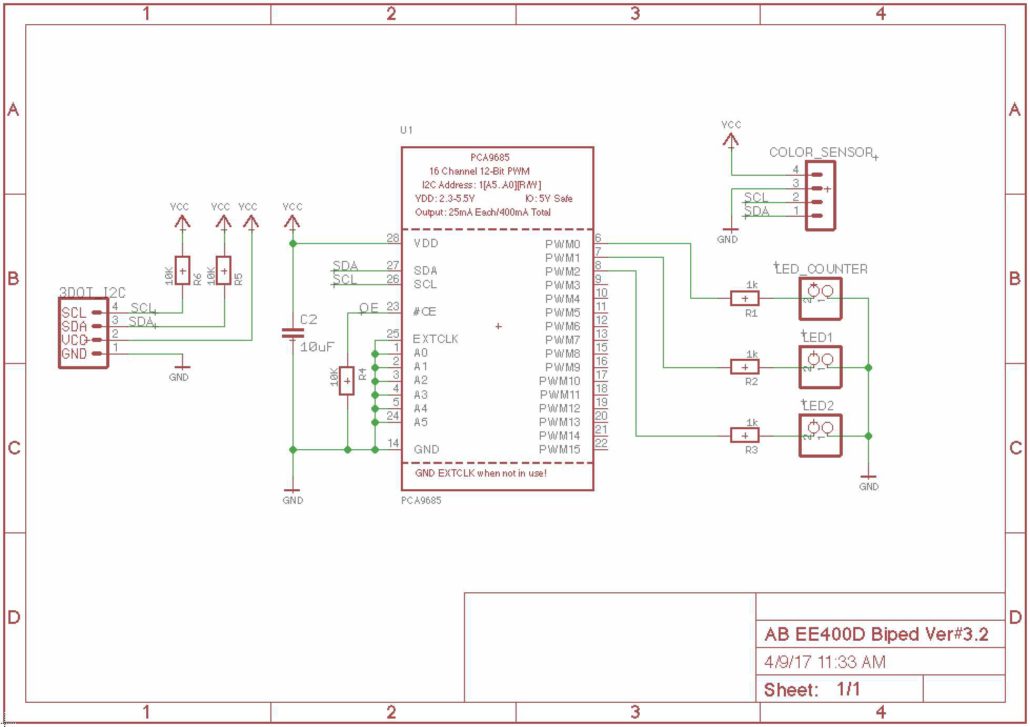

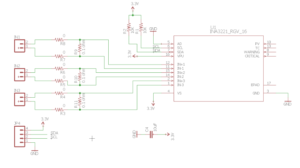

Alexander Clavel – BiPed Project Manager

Nicholas Jacobs – Spiderbot Project Manager

Jesus Enriquez – Velociraptor Project Manager

Overview:

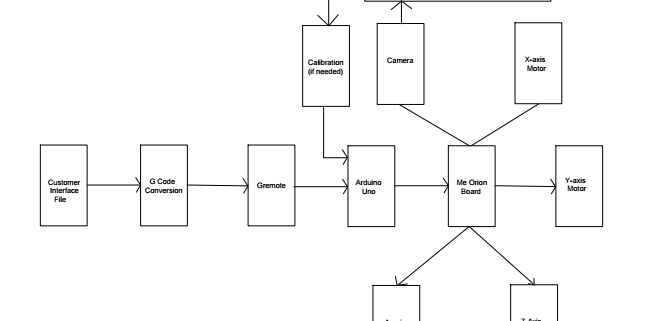

The BiPed and Velociraptor will participate in a game of PacMan. Both robots will start on opposite ends of a maze with the BiPed initially acting as PacMan and trying to avoid the other robot. The BiPed and the Velociraptor will attempt to collect as many “dots” or points as possible within the allotted time limit. The Velociraptor will initially act as the “ghost” and try to catch Pacman before the end of the game while also collecting points. The game will start once the Spiderbot has reached its position and begins video feed. The game will last a maximum of 30 minutes.

Rules:

– Spiderbot will walk into the maze and then place itself above the maze for video set up

– Biped will start off as “Pacman” while the velociraptor starts as the “ghost”

– Both robots will start in different ends of the maze

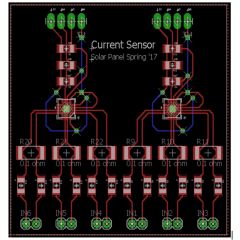

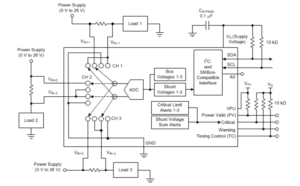

– There will be red dots on the ground which will be “counted” and displayed on both robots as they pass over a dot.

– If the Velociraptor reaches and “eats” the BiPed before the 30 minutes then the raptor wins

– If the Velociraptor does not “eat” the BiPed then the winner will be determined by who has the most dots counted.

– There will be special grid squares to make the velociraptor vulnerable to being “eaten” and will reverse the rolls

– If the BiPed can reach the velociraptor within the time limit then the velociraptor loses.

– Live aerial video feed will be provided by the Spiderbot

– Time limit of 30 minutes OR when the ghost catches Pacman OR when one group reaches 5 dots first.

– If a robot falls over, that will count as a deducted point and they will start again at their starting area.

– Points will be deducted at the end of the game by subtracting the endgame amount from the number of times the robot has fallen

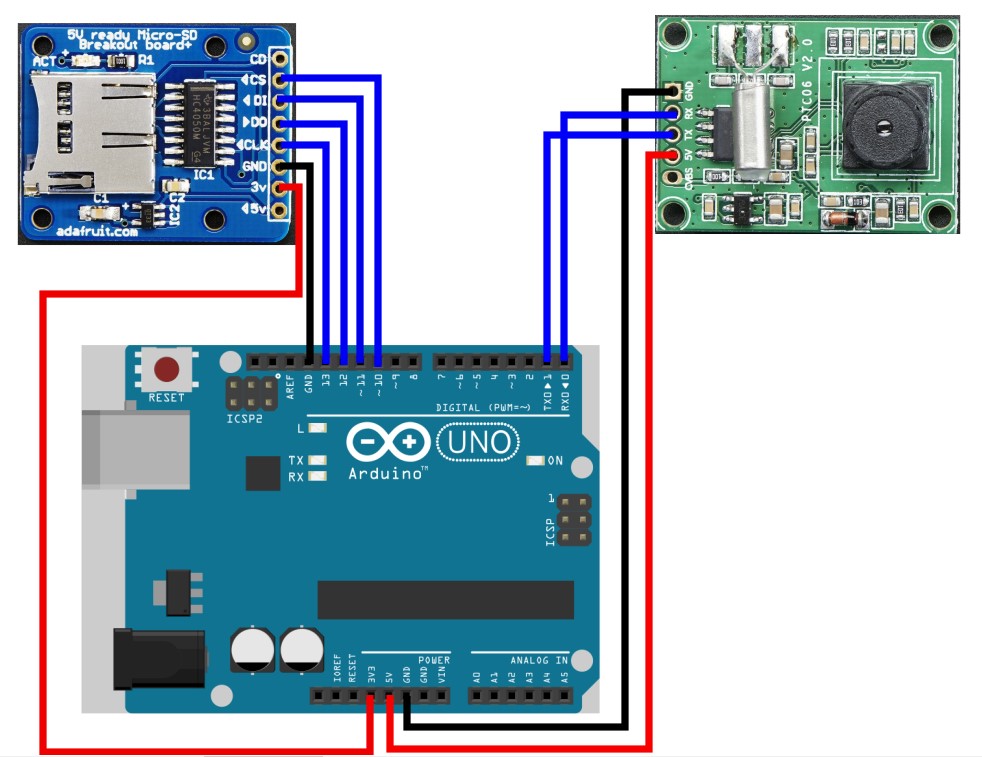

View and Control:

– BiPed and Velociraptor will view the gaming field through video feed provided by the Spiderbot

– Both Robots will be controlled through the arxterra control panel

Terrain:

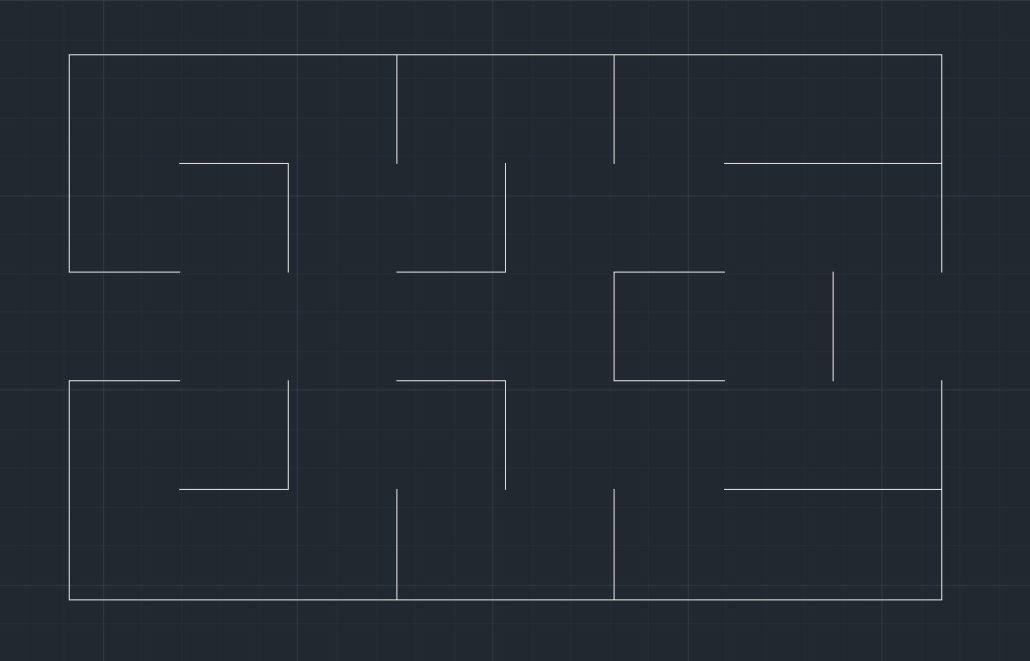

– 35 in x 56 in area

– Flat paper taped across the tiled floor of the classroom

– No physical walls

– The Maze will be printed on paper

– 7 inch width for walkways for the robots

– Roof with steel area for magnet and supports made of wood for the spiderbot height TBD

Game map to be updated , Dots to be added***

SpiderBot and Velociraptor Starting Point – Left Opening

BiPed Starting Point – Right Opening