Written By Jefferson Fuentes

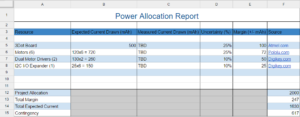

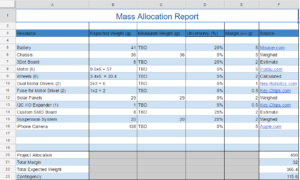

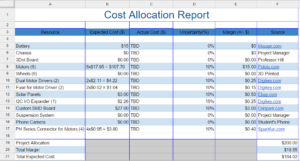

Introduction:

The Arxterra mission control panel is to work in conjunction with the Arxterra phone app, transmitting and receiving information to and from the robot. It serves an extended/secondary means of control with more capability than the Arxterra app. The control panels main purpose is to increase the capable range for controlling the robot, theoretically to anywhere in the world, as opposed to the limit of the Bluetooth range. It is also capable of providing more telemetry to user than the app, i.e. video feed, pitch, roll, speed, robot location, and any other as needed information.

Requirements:

The Spring ’17 SpiderBot is required utilize the Arxterra phone app to control the robot remotely via bluetooth. SpiderBot is also required to provide aerial live video feed capable of covering the entire arena of the end-of-the-semester game to other participating robots. The video feed will be accomplished by SpiderBot’s ability to hoist itself up in the air through use of a grappling system.

Set Up:

To utilize the Arxterra mission control panel a quick setup is required. The following is a walkthrough of the process.

Part 1: Arxterra App Initialization

The first step is to attain permission from the administrator to access and download Arxterra app. The Arxterra app uses a Bluetooth link to connect to SpiderBot to facilitate movement control.

Fig 1. Arxterra App initial launch screen

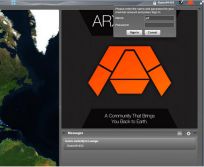

On boot up, the Arxterra app begins in the remote control function(fig 1) by default. This function allows us to control the robot with a phone via a Bluetooth connection. To control the robot using the control panel, the next step is to switch over to community mode. This can be achieved by pressing the function icon on the app (fig 2), which allows us to toggle between robot and community mode.

Fig 2. Toggle Function

Toggling community mode launches a sign in window (fig 3), with two required fields Robot name and Pilot name or names. These two fields are used to define which robot is to be used, and who has access to controlling it through the Arxterra mission control panel. Confirmation of success is given by a message at the bottom left corner of screen, “Live cast published” (fig 4)

At this point, all necessary steps have been achieved concerning the Arxterra app. As an added method of determining whether the Arxterra app and arxterra control panel are working properly. A simply check on the app will verify functionality. Clicking the camera icon after the login procedure will display basic camera feed status as well as a display window showing what the phone is streaming(fig 5).

Fig 3. Arxterra login window Fig 4. Login Success

Fig 5. Connection Test

Part 2: Arxterra Mission Control Panel Initialization

Procedure:

Next is the Arxterra Mission Control Panel interface setup. The control panel is used as an extended/secondary mode of control over the robot. Its main function is an increased range for controlling the robot, as well as providing more telemetry of the robot. In the case of SpiderBot, it will serve as a method of providing video feed in the end of semester games.

To access the control panel, the following link is provided: Arxterra Mission Conrol Panel. Accessing the control panel brings up the window seen in fig 5. This is the main window where login is accessible.

Fig 6. Main Arxterra Control Panel Window

To login, simply click on the Guest# icon, which opens a drop-down login widget (fig 7). Currently the control panel is in the alpha stage. The control panel itself is fully functional, but other functions, such as username and password, are not. At this time, no password is necessary. To login, the name parameter will simply be the pilot name from the Arxterra App (fig 3).

Fig 7. Control Panel Login

Successful login is verified by a marker on the map. When the marker is selected (fig 8), the robot to be commandeered pops up. Displaying the name of the robot to be controlled, the status of the robot as the user, and an icon which once selected teleports user to control panel.

Fig 8. Commandeering of robot

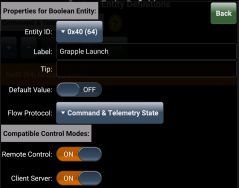

Taking command of the robot shows the GUI of the control panel (fig 9). The control panel is capable of displaying several telemetry options. For SpiderBot, the video feed component is an important factor, as well as the movement control segment. Arxterra is capable of more telemetry options such as phone readings, and any custom commands defined by user. The Arxterra mission control panel could optimize SpiderBot’s aerial video feed by implementing a full screen mode.

Fig 9. Arxterra mission control panel

Conclusion:

The Arxterra phone applet and Arxterra mission control panel are seamlessly interfaced. The ability to control a robot from one or the other is a nice feature to have. In the case of the Spring 2017 SpiderBot, the requirements are to provide live streaming video for the end of semester games. This is easily achieved using both the app and control panel. The Arxterra control panel has the added features of multiple pilots capable of being onboard the robot, as well as a chat feature which will allow for trash talking amongst the robots during the game.

Resources:

- http://web.csulb.edu/~hill/ee400d/Technical%20Training%20Series/3DoT/_3DoTTrainingDocumentation.pdf