Fall 2016 Solar Panels: System Block Diagram Update

By Stephan Khamis (Mission, Systems, and Test)

Approved By Inna Echual (Project Manager)

Table of Contents

Introduction

As a result the feedback we received during the critical design review (CDR), we decided the system block diagram for our system. This blog post contains our most up-to-date system block diagram for the Solar Panel system of the Pathfinder project. Within this blog post you will learn about the changes we have made since the CDR to update this document.

Previous System Block Diagram

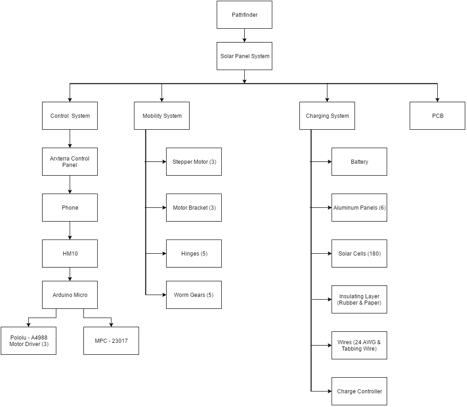

Figure 1: System Block Diagram Presented During CDR

Figure 1 shows our the System Block Diagram that we presented during our CDR. The first major difference we had to make was the switch from an Arduino Leonardo to an Arduino Micro. Per the customer, the use of the MPU – 6050 was told to be removed because the panels never had an explicit requirement for autonomous recovery if the rover fell over. We also added around 32 solar cells to help us make our 12V 1A mark of charge to charge our battery system. We also decreased the number of motorized folds to 3 rather than 5 because the stepper motors on the sub sided panels would be completely destroyed if they tried to recover the rover to an upright position.

Updated System Block Diagram

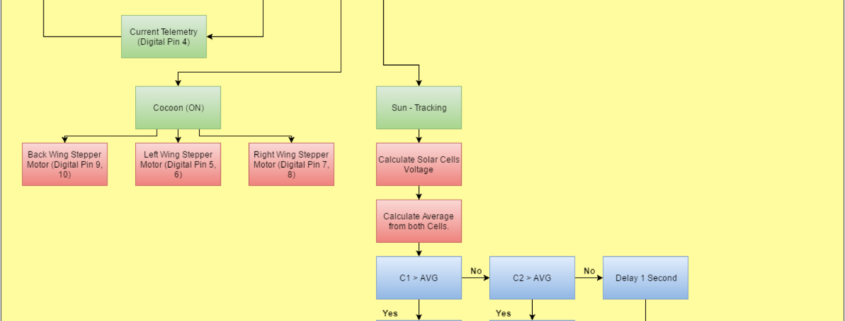

Figure 2: Updated System Block Diagram

Figure 2 shows our solar panel system’s updated system block diagram. The system block diagram explains an overall understanding of what the Solar Panel system entails. Because the pathfinder is an integrated project, also includes a portion of the Chassis system and how we are interfacing with one another electronically and a legend on the top right to help detect what the different colors and arrows mean.

On the left-hand side, you will notice the Solar Panel System, and on the right-hand side, you will notice the Chassis system. Since the Solar Panel is our priority and project, it is much more detailed than the basic interfacing that is shown on the Chassis system. Both the Solar Panel and Chassis system are using an Arduino But, the Solar Panel is using an Arduino Micro rather than a Leonardo. The two Arduinos will be interfacing with one another via an I2C. We also decided to add an MPC-23017 in order to make room for our reed switches, which will be used to prevent the cocooning mechanism from hitting the adjacent panels, which can possibly damage the cells.

Looking on the left-hand side of the overall System Block Diagram, it shows the power connections between the solar cells, battery, Pololu – A4988 motor drivers. Connecting to the motor drivers are the 3 stepper motors that will be used to help cocoon the Solar Panels. Connected to the solar cells is a charge controller that will help prevent the solar cells from providing more than 12V of charge, which is the maximum capacity of the battery.

Now looking at the right-hand side you will see the interfacing and communication going on between the Chassis and Solar Panel systems. Through the I2C connection of the Arduino Leonardo and Micro, the Leonardo will be able to help send commands to our Arduino Micro using the Arxterra Application/Control Panel. The Arxterra application will be controlled through an Android phone (Provided by the Chassis group) and will connect to the Arduino Leonardo via HM-10 BLE Bluetooth.

Future Updates

As of now, there are no future updates that I plan to change within the now updated System Block Diagram.