Preliminary Project Plan – Prosthetic Arm (Fall 2016)

WORKDOWN BREAKDOWN STRUCTURE

The following Work-down Structure is the second iteration we got after we organize the potential schedule for the semester.

PROJECT SCHEDULE

The project schedule was done to give a basic idea to the group on the timing framework, and to work as a reference to know if the tasks are being done in a timely manner.

From the schedule we conclude that regardless of the video-taking that we are going to be doing to provide documentation about the project, we will spend major part of the project performing experiments on the arm system, and making sure it works as a whole.

The schedule for the project of the Prosthetic Arm is provided in HERE

SYSTEM RESOURCE REPORTS

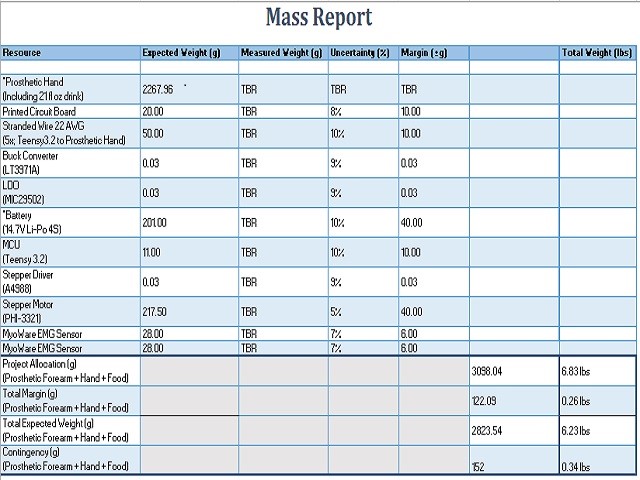

Mass Report

For this initial mass resource report for the Prosthetic Arm project, the total expected weight of internal components (inclusive of an estimated 5 lbs from the Prosthetic Hand and 21 fl. oz. drink combined, per our L2-3 requirement) totals to 6.23 lbs, with a margin of 0.26 lbs. Given a required capacity to lift up to 6.83 lbs, the current report meets the requirement with a contingency of 0.34 lbs. The measured weight of the majority of our components is to be resolved, as we have not yet received many of the parts and validated their actual weights on a scale, however given margins and uncertainty, the actual weights are predicted to be lower than the expected weights.

Power Report

In this initial iteration of the power resource report for the Prosthetic Arm project, the total expected current totals to 3242 A, inclusive of supplying the Prosthetic Hand with an estimate of 2A on 12V and 1A on 5V. The total margin for the current sums up to 0.840 A, with a remaining contingency of 0.418 A.

Cost Report

This first iteration of the cost resource report for the Prosthetic Arm project shows an expected project cost of $286.48, with a margin of $63.87 for the electronic components of the project. With respect to these estimates, the contingency amounts to $149.65, which will be allocated to the manufacturing components specified in the overall Project Cost Estimate.

Cost

Mass/ Power

Buck Converter LT3971A (10-Lead MSOP Packaging Weight)

PROJECT COST ESTIMATE

The project estimate is based on the budget and materials that we have purchased and looked at. It provides margin and it confirms our estimate provided previously in the Preliminary Design Document.