Spring 2016: 3DoT David Gear Instability

BY: Andrew Saprid ( Manufacturing Engineer)

Introduction:

By assembling the gears into the bottom plate, making the connection was going to be an issue of stability and movement for the gears. The project manager and manufacturing engineer went to Lowes to buy screws for the connection. But turns out that the holes on the bottom plate did not print the exact measurement on Solid-works, making the holes too small or big.

Some tests were being made for the small motors and big motors by the electronics engineer and manufacturing engineer.

Requirements

Level 2 system requirement follows:

- The 3DoT David shall use two micro motors for the movement system of the robot.

Testing #1

The project manager suggested that the screw would fit exactly on the gear, but make the hole a little bit bigger on the bottom plate, so that the gear would rotate on the bottom plate. The manufacturing engineer drilled the hole on the bottom plate, but broke some of the planks that were super glued into the bottom of the bottom plate. He cut off the screw to cut the weight of the screw, which may not make a difference for stability. He noticed the friction of the bottom plate may affect the movement of the gears.

Gorilla tape was used to tape the planks to the bottom of the bottom plate. With using the small motor that the project manager bought in Amazon, they tested the motor to see if it will work, and it turns out that the friction, the screws, and the gorilla tape were causing problems with the motor turning the gears.

Testing #2: White gears

Since red gears may be heavy for the small motors to run, white gears are placed on the wooden prototype for testing. They tested them with the small motor the project manager bought. They were running smoothly. The white gears were light. Driving a nail through the center of the hole of the gear will insure stability if the nail is driven to the wood straight downward. The small motor will run well with these gears, but the project manager wanted to use the red gears because they were stable and strong to withstand the weight of the legs. With legs and the joint attached to the white gears, the leg was putting weight into the gears, which caused instability of the gear train.

White Gear Testing With Motor VIdeo Link

Testing #3:Testboard, Oil, and Washers

In order to make the gears move freely on the bottom plate, washers and oil will be added. These were bought at Home depot.

TestBoard

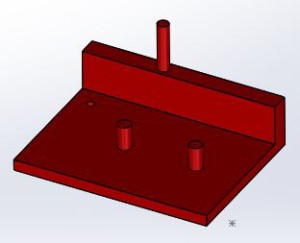

A test board was made in Solid-works to test the gear stability, movement, and friction. The original test board was not documented. The test board below has been tested, and the results of the testing have damaged the cylindrical extrusions by hammering a nail to it to make the gears stay in place as the motors drive the gear. By putting oil into the plate, and washer underneath the gear, the gear was able to move freely. The cylindrical extrusions did its job stabilizing the gear train. Finding a nail, screw, or etc to hold the gears in place is in progress.

Conclusion

The electronics and manufacturing engineers did 3 tests for the white gears, red gears, and the extrusion of the bottom plate. The white gears are not going to be used because they are too light. The red gears will be used instead. They will be able to withstand the weight of the legs. Kent used the big motors. Big motors were able to move the red gears. Motors are still being investigated and researched by the electronics engineer for a small motor with more torque to the turn the gears better.Testing #3 could be the solution to the gear stability, friction, and movement. In order for the gears to move properly, perfection and accuracy is key.

Red Gear Testing With Motor Video Link