Spring 2016 A-TeChToP Manufacturing Design Studies

By: Mimy Ho (Manufacturing Engineer, Central Sensor Suite)

Marena Willian (Manufacturing Engineer, Seizure Watch)

Central Sensor Suite

Mimy Ho (Manufacturing Engineer)

Pros and Cons from Spring 2015 ATeChToP projects:

Pros:

ATeChToP Wednesday

- The 3D case design was used to fit a Lilypad Arduino and PCB.

- Using thin, insulated wires. The advantages are light and avoid short circuit.

ATeChToP Friday

- Placed the phone horizontally in front of the chest harness to provide comfortness for child while playing. If the phone is placed vertically, the phone size would be too big compared to the child’s chest size and could limit himself from playing

- The phone can be attached to the chest harness like a GoPro.

Cons:

ATeChToP Wednesday

- Homemade PCB costs to much space for the case which made the case really thick.

- The wiring is placed all around the sweater.

- The sweater is designed for a specific child, and cannot be fit for different age.

- All the components are poking out, when a child is jumping jack, the device is bouncing up and down.

- 3D printed case is too bulky

- Too many pouches around the sweater to hold the phone, 3D case.

ATeChToP Friday

- The pulse oximeter is placed on the lower of the left earlobe, and there is the black cable connected to the Arduino Lilypad limit a child to do head rotation. If a child is running and do too many head rotation the pulse oximeter can peel off from the earlobe

- The black cable in the back of the harness that connected the Arduino Lilypad to temperature sensor probe DS18B20. Based on my observation, the temperature probe is placed under the armpit of child, and I child uses his arm to keep the probe in place.

Design solution

The device shall have: (based on Preliminary Design Blog Post)

Sensors:

– the temperature sensor is placed on a chest area

– the accelerometer and gyroscope is placed in front of a chest

– the blood oximeter is placed on the ear lobe

– the pulse sensor is placed near the chest

– the ECG electrodes is placed on the underside of the upper arm of a child

Android phone

Pro Mini Arduino board

Power supply

Bluetooth

The design of the device is based on the the idea of Polar H7 Bluetooth Smart Heart Rate Sensor. It is a heart rate sensor strap which connect to the phone app via bluetooth to monitor the heart rate.

http://www.polar.com/us-en/products/accessories/H7_heart_rate_sensor

And the idea of Neopine GoPro product.

http://www.gearbest.com/camping/pp_106537.html?currency=USD&gclid=Cj0KEQiAr8W2BRD2qbCOv8_H7qEBEiQA1ErTBko8AOJ68oQgkbwiwKBbzYHc42o9y-nkqVIIphlTaEIaAvsA8P8HAQ

Design Innovation

- The super ATeChToP design of the central sensor suits shall containing 2 different parts:

- The armband for an android phone

- The harness including a chest strap and a single shoulder strap with 3D printed case placed horizontally in the front of the chest strap

Explanation: Since the temperature sensor, pulse sensor and the ECG electrodes shall apply directly to the skin near a heart, so the harness will design to wear directly to the skin and under a shirt. Because of that, the horizontal strap requires to be light and comfort for wearers.

By studying the ATeChToP Friday Spring 2016, the back of the harness contains too many wires sticking out which can limit a child’s movements. And an Android phone shall not be placed on the strap because the phone and the printed case combining together may be too bulky and heavy for a child to wear. And the phone can recreate more heat and SAR level which can harm a child when wearing under the shirt. So, I decide to separate the harness and the armband for the phone.

- The image above demonstrates the model of the chest harness of central sensors suit by using Solidwork. Wiring will only take place on one side of the horizontal strap which connecting to the shoulder strap. On the other side of the harness will have velcro to adjust the size of the strap. To be able to adjust the size shoulder strap, velcro will place in the back of the shoulder strap.

- Printed 3D case shall be including Arduino Pro Mini, Power Supply, Accelerometer and Bluetooth. In the back of the printed case shall have holds that wiring to sensors. The case shall be designed with small different compartments to keep each board, so they are not touch each other.

- Size: 4.5in x 2in x 1.5in

- Material: PLA (which is available based on division manager’s suggestion)

- Screws size: #2 x 1/2 in. Flat Head Phillips with 0.086in in diameter.

- Advantages of the new design:

- Adjustable strap to fit children from 5 – 11 years olds

- Washable

- Personal fashion style since the harness is wear inside a top

Seizure Watch

Marena William (Manufacturing Engineer)

Trade-off study for 3D printing materials. [1], [2], [3],[4], [5],[6]

| PLA | ABS | NinjaFlex | |

| Temperature | 65⁰C | Up to 105⁰C | Up to 120⁰C |

| Flexibility | Not flexible | Moderate flexibility | Highly elastic (silicon like) |

| Strength/breakpoint | 67 lbs | 67 lbs | 72 lbs |

| Water Resistance | Yes | Yes | Water and oil resistant |

| Density | 1.25 g/cm3 | 1.03 to 1.38 g/cm3 | 1.2 g/cm3 |

| Cost (estimate) | 24.80 $/Kg | 30.13 $/Kg | 86.6 $/Kg |

| Availability | Available(more than one source) | Available

(Division manager) |

Not available by Maker Society or division manager/searching for sources |

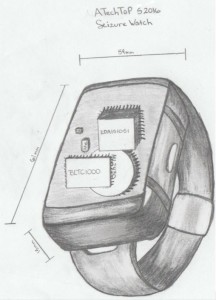

1- Initial draft of the wristwatch

2- To fit all sizes, the wristband strap will have an adjustable buckle.

PCB:

The PCB will contain the EDA sensor, the accelerometer, clock and the Atmel ATBTLC1000 chip. Voltage regulators and resistors will be added to the PCB as needed.

The PCB is to be manufactured by OSH Park warehouse with estimated cost of $5 per square inch. Order takes around 14 days. (Source Manufacturing Division manager).

Component Manufacturing:

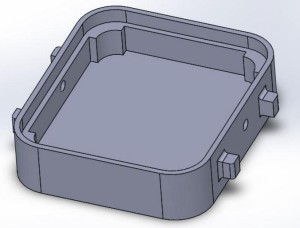

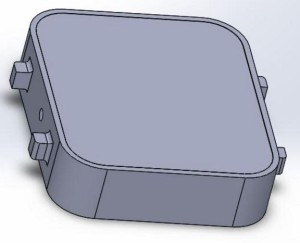

3D Printing is to be done from PLA or ABS unless better sources are located.

The housing will be sprayed with silicon to add a water-resistant layer and the electrodes channels are to be sealed with silicon to prevent water/sweat getting to the PCB. for waterproofing the watch. An o-ring will be run between the lid and the housing. and we are not using NinjaFlex anymore we will be printing from PLA.

The compartment for the watch as modeled in SolidWorks. The components will be housed inside.

Wiring Harness (The cable tree):

The housing include the PCB (EDA sensor, accelerometer, clock and Atmel ATBTLC1000 chip) and the battery. The electrodes are to be placed at the ventral side of the distal forearm (bottom of the wristband) and the wires are to be run on the inside side of the watch strip.

Reference:

[1] “Strength of different filaments | Ultimaker,” Ultimaker.com. [Online]. Available at: https://ultimaker.com/en/community/8575-strength-of-different-filaments. [Accessed: 21-Feb-2016].

[2] “Density of Acrylonitrile Butadiene Styrene (ABS),” Acrylonitrile Butadiene Styrene (ABS) Material Properties. [Online]. Available at: http://www.makeitfrom.com/material-properties/acrylonitrile-butadiene-styrene-abs/. [Accessed: 21-Feb-2016].

[3] “Density of Polylactic Acid (PLA, Polylactide),” Polylactic Acid (PLA, Polylactide) Material Properties. [Online]. Available at: http://www.makeitfrom.com/material-properties/polylactic-acid-pla-polylactide/. [Accessed: 22-Feb-2016].

[4] “SDS NinjaFlex,” fennerdrives, 15-Dec-2015. [Online]. Available at: www.fennerdrives.com. [Accessed: 22-Feb-2016].

[5] “www.3ders.org,” 3ders.org. [Online]. Available at: http://www.3ders.org/pricecompare/. [Accessed: 22-Feb-2016].

[6] “NinjaFlex Sapphire Blue TPE 3D Printing Filament – 3.00mm,” NinjaFlex Sapphire Blue TPE 3D Printing Filament – 3.00mm. [Online]. Available at: https://www.matterhackers.com/store/3d-printer-filament/ninjaflex-sapphire-blue-tpe-3d-printing-filament-3mm?rcode=gat9hr. [Accessed: 22-Feb-2016].