Building the UFO 1.01 (Code Name: Buster)

By Tuan Vo, Project Manager

First attempt.

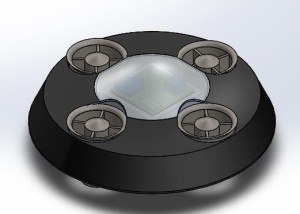

For our build, we will be using a foam body sandwiched between two stiff and flat carbon fiber donuts. We will use a clay mold to form a carbon fiber shell top piece that will give the UFO its characteristic dome shape. The fans mount into the top donut piece, not the dome shell.

Here are some pictures from our build.

Model by Juan Montano.

Below is a proposed picture of what was going to happen.

The foam will be carved out into a hollow cylinder. We will cut out smaller CF circle on top and a bigger CF circle on the bottom. Using a 55mm drill, we can cut the 4 holes on the top to mount the fans and four holes on the bottom of the bottom circle for the air outlet. We can then cut the foam to whatever height we want, and we can also use a hot knife to cut out the slanted skirt that gives the UFO its characteristic look.

Below is the picture of the proposed clay mold we will be using for the top dome carbon fiber shell. After 30minutes of hand molding, we were able to come up with a rough figure.

STOP!

During this build, we encountered several hard challenges and problems:

- Hand cutting a foam piece with a hot knife is extremely difficult. The plastic is toxic and Tuan Vo had to use a respirator in order to cut it safely. Also, foam is very unforgiving to mistakes and erroneous cuts. After a lot of practice on a smaller foam piece, we decided that there was no way to make the foam look good even with great skill and precision. The end product on the practice piece is a charred and uneven cylinder; it looks non-presentable and not very usable.

- Clay modeling, although easy to do, is not easy to create a perfect dome. There are constantly holes and flat spots present through many forming. The potential of clay could not be achieved due to lack of a spinning table and experience. No matter how much time we put into it, we will not achieve a mold good enough to lay carbon fiber on.

- The vent, although functional and adjustable, adds height to the UFO making it look very awkward.

After much discussion and consideration, we decided to scrap this build and go for a new approach. This build would work if we were preferred 1. Shorter build time 2. Less weight 3. Less design time while increasing cost and lowering aesthetic standards.

In the new build, UFO 1.02, we will be taking a more time consuming and precise approach in creating the UFO.