Debugging Wire Library

By: Electronics and Control Engineer – Kevin Armentrout

Table of Contents

Debugging the Wire Library

Problems with the Wire Library and the 3DoT library

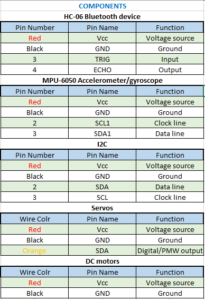

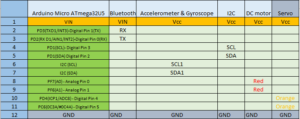

The wire library uses an inefficient system of transferring data via I2c which can be interrupted during serial communications. When this happens your 3DoT program, and any other Arduino program that is using both of these communication methods will freeze. This is a very difficult problem to experience and diagnose as it may be the most frustrating thing you can experience, an intermittent bug.

Fortunately, the solution is available, but it requires modifying the header files of any I2c implemented device to ensure that the libraries are compatible. I modified the MPU-6050 library to prevent this run-over and implemented the time-out that is available in the I2C Master library. This eliminated all bugs associated with I2C and serial communications that I had experienced. The I2C Master library is found here. Completion of this interface between the 3DoT library and the I2C library accomplishes the IMU action item.

Project Source Code Gyro Debugging:

/* Author = helscream (Omer Ikram ul Haq)

Last edit date = 2014-10-08

Website: http://hobbylogs.me.pn/?p=47

Location: Pakistan

Ver: 0.1 beta — Start

Ver: 0.2 beta — Bug fixed for calculating “angle_y_accel” and “angle_x_accel” in “Gyro_header.ino” file

*/

#ifndef gyro_accel.h

#define gyro_accel.h

extern int accel_x_OC, accel_y_OC, accel_z_OC, gyro_x_OC ,gyro_y_OC, gyro_z_OC; // offset variables

extern float temp_scalled,accel_x_scalled,accel_y_scalled,accel_z_scalled,gyro_x_scalled,gyro_y_scalled,gyro_z_scalled; //Scaled Data variables

void MPU6050_ReadData();

void MPU6050_ResetWake();

void MPU6050_SetDLPF(int BW);

void MPU6050_SetGains(int gyro,int accel);

void MPU6050_OffsetCal();

#endif

/* Author = helscream (Omer Ikram ul Haq)

Last edit date = 2014-10-08

Website: http://hobbylogs.me.pn/?p=47

Location: Pakistan

Ver: 0.1 beta — Start

Ver: 0.2 beta — Bug fixed for calculating “angle_y_accel” and “angle_x_accel” in “Gyro_header.ino” file

*/

#include <Arduino.h>

#include <Wire.h>

#include “gyro_accel.h”

#include “I2C.h”

// Defining the important registers

#define MPU6050_address 0x68

// —— SELF Test Trim Factors ———————-

#define MPU6050_self_test_x 13 // R/W

#define MPU6050_self_test_y 14 // R/W

#define MPU6050_self_test_z 15 // R/W

#define MPU6050_self_test_A 16 // R/W

// —– Sample Divider ——————————-

#define MPU6050_sample_div 25 // R/W

/* Sample Divider Discription

Sample rate = 8/(1 + Sample rate divider) [kHz] if DLPF is disabled

Sample rate = 1/(1 + Sample rate divider) [kHz] if DLPF is enabled

*/

// —– Configration ———————————

#define MPU6050_config 26 // R/W

#define MPU6050_gyro_config 27 // R/W

#define MPU6050_accel_config 28 // R/W

// —– Data ———————————————

#define MPU6050_data_start 59

#define read_bytes 14

// —– Power Management ———————————

#define MPU6050_PWR1 107

#define MPU6050_PWR2 108

// —– Defining Constant ——————————–

#define g 9.81 // Gravitational accelration

// Variables

int temp=0, accel_x=0, accel_y=0, accel_z=0, gyro_x=0, gyro_y=0, gyro_z=0; // Raw values varaibles

int accel_x_OC=0, accel_y_OC=0, accel_z_OC=0, gyro_x_OC=0 ,gyro_y_OC=0, gyro_z_OC=0; // offset variables

float temp_scalled,accel_x_scalled,accel_y_scalled,accel_z_scalled,gyro_x_scalled,gyro_y_scalled,gyro_z_scalled; //Scalled Data varaibles

float accel_scale_fact = 1, gyro_scale_fact = 1; // Scale factor variables

// **************************************************************************

// Functions for MPU6050

// **************************************************************************

void MPU6050_ReadData(){

//Wire.beginTransmission(MPU6050_address);

//Wire.write(MPU6050_data_start);

//Wire.endTransmission();

I2c.write(MPU6050_address, MPU6050_data_start);

//int read_bytes = 14;

//Wire.requestFrom(MPU6050_address,read_bytes);

I2c.read(MPU6050_address,read_bytes);

if(I2c.available() == read_bytes){

accel_x = I2c.receive()<<8 | I2c.receive();

accel_y = I2c.receive()<<8 | I2c.receive();

accel_z = I2c.receive()<<8 | I2c.receive();

temp = I2c.receive()<<8 | I2c.receive();

gyro_x = I2c.receive()<<8 | I2c.receive();

gyro_y = I2c.receive()<<8 | I2c.receive();

gyro_z = I2c.receive()<<8 | I2c.receive();

}

/* if(Wire.available() == read_bytes){

accel_x = Wire.read()<<8 | Wire.read();

accel_y = Wire.read()<<8 | Wire.read();

accel_z = Wire.read()<<8 | Wire.read();

temp = Wire.read()<<8 | Wire.read();

gyro_x = Wire.read()<<8 | Wire.read();

gyro_y = Wire.read()<<8 | Wire.read();

gyro_z = Wire.read()<<8 | Wire.read();

} */

accel_x_scalled = (float)(accel_x-accel_x_OC)*accel_scale_fact/1000; // divided by 1000 as the Scale factor is in milli units

accel_y_scalled = (float)(accel_y-accel_y_OC)*accel_scale_fact/1000;

accel_z_scalled = (float)(accel_z-accel_z_OC)*accel_scale_fact/1000;

gyro_x_scalled = (float)(gyro_x-gyro_x_OC)*gyro_scale_fact/1000;

gyro_y_scalled = (float)(gyro_y-gyro_y_OC)*gyro_scale_fact/1000;

gyro_z_scalled = ((float)(gyro_z-gyro_z_OC)*gyro_scale_fact/1000);

temp_scalled = (float)temp/340+36.53;

}

// ————————————————

// Reset and wake up the MPU6050

// ————————————————

void MPU6050_ResetWake(){

Serial.println(“Resetting MPU6050 and waking it up…..”);

Wire.beginTransmission(MPU6050_address);

Wire.write(MPU6050_PWR1);

Wire.write(0b10000000);

Wire.endTransmission();

delay(100); // Waiting for the reset to complete

Wire.beginTransmission(MPU6050_address);

Wire.write(MPU6050_PWR1);

Wire.write(0b00000000);

Wire.endTransmission();

}

// ————————————————

// Setting up the DLFP

// ————————————————

void MPU6050_SetDLPF(int BW)

{

if (BW < 0 || BW > 6){

BW = 0;

}

Wire.beginTransmission(MPU6050_address);

Wire.write(MPU6050_config); // Address to the configuration register

/* config Discription —- x x 0 0 0 F2 F1 F0

I am only intrested in the Digital Low Pass Filter (DLPF)

F2 F1 F0 Bandwidth [Hz]

0 0 0

0 0 1 184

0 1 0 94

0 1 1 44

1 0 0 21

1 0 1 10

1 1 0 5

*/

Wire.write(BW);

Wire.endTransmission();

}

// ————————————————

// Setting up the Accelrometer and Gyro Gains

// ————————————————

void MPU6050_SetGains(int gyro,int accel)

{

byte gyro_byte,accel_byte;

// Setting up Gyro

Wire.beginTransmission(MPU6050_address);

Wire.write(MPU6050_gyro_config); // Address to the configuration register

if (gyro==0)

{

gyro_scale_fact =(float)250*0.0305; // each data is of 16 bits that means, 250 is divided along 2^(15)-1 = 32767 so for milli degree/s 0.0305 = 1000/32767

gyro_byte = 0b00000000;

}else if (gyro == 1)

{

gyro_scale_fact = 500*0.0305; // each data is of 16 bits that means, 500 is divided along 2^(15)-1 = 32767 so for milli degree/s 0.0305 = 1000/32767

gyro_byte = 0b00001000;

}else if (gyro == 2)

{

gyro_scale_fact = 1000*0.0305;// each data is of 16 bits that means, 1000 is divided along 2^(15)-1 = 32767 so for milli degree/s 0.0305 = 1000/32767

gyro_byte = 0b00010000;

}else if (gyro == 3)

{

gyro_scale_fact = 2000*0.0305; // each data is of 16 bits that means, 2000 is divided along 2^(15)-1 = 32767 so for milli degree/s 0.0305 = 1000/32767

gyro_byte = 0b00011000;

}else

{

gyro_scale_fact = 1;

}

Wire.write(gyro_byte);

Wire.endTransmission();

Serial.print(“The gyro scale is set to “);

Serial.print(gyro_scale_fact);

Serial.println(” milli Degree/s”);

// Setting up Accel

Wire.beginTransmission(MPU6050_address);

Wire.write(MPU6050_accel_config); // Address to the configuration register

if (accel==0)

{

accel_scale_fact =(float)2*g*0.0305; // each data is of 16 bits that means, 2g is divided along 2^(15)-1 = 32767 so for milli m/s^2 0.0305 = 1000/32767

accel_byte = 0b00000000;

}else if (accel == 1)

{

accel_scale_fact = 4*g*0.0305; // each data is of 16 bits that means, 4g is divided along 2^(15)-1 = 32767 so for milli m/s^2 0.0305 = 1000/32767

accel_byte = 0b00001000;

}else if (accel == 2)

{

accel_scale_fact = 8*g*0.0305;// each data is of 16 bits that means, 8g is divided along 2^(15)-1 = 32767 so for milli m/s^2 0.0305 = 1000/32767

accel_byte = 0b00010000;

}else if (accel == 3)

{

accel_scale_fact = 16*g*0.0305; // each data is of 16 bits that means, 16g is divided along 2^(15)-1 = 32767 so for milli m/s^2 0.0305 = 1000/32767

accel_byte = 0b00011000;

}else

{

accel_scale_fact = 1;

}

Wire.write(accel_byte);

Wire.endTransmission();

Serial.print(“The accel scale is set to “);

Serial.print(accel_scale_fact);

Serial.println(” milli m/s^2″);

}

// ————————————————

// offset calibration

// ————————————————

void MPU6050_OffsetCal(){

Serial.println(“Calibrating gyroscope …. dont move the hardware ……….”);

int x=0,y=0,z=0,i;

MPU6050_ReadData();

MPU6050_ReadData();

// Gyro Offset Calculation

x=gyro_x;

y=gyro_y;

z=gyro_z;

for (i=1;i<=1000;i++){

MPU6050_ReadData();

x=(x+gyro_x)/2;

y=(y+gyro_y)/2;

z=(z+gyro_z)/2;

Serial.print(“.”);

}

Serial.println(“.”);

gyro_x_OC=x;

gyro_y_OC=y;

gyro_z_OC=z;

Serial.print(“gyro_x register offset = “);

Serial.println(x);

Serial.print(“gyro_y register offect = “);

Serial.println(y);

Serial.print(“gyro_z register offset = “);

Serial.println(z);

// Accel Offset Calculation

Serial.println(“Calibrating accelrometer …. dont move the hardware ……….”);

x=accel_x;

y=accel_y;

z=accel_z;

for (i=1;i<=1000;i++){

MPU6050_ReadData();

x=(x+accel_x)/2;

y=(y+accel_y)/2;

z=(z+accel_z)/2;

Serial.print(“.”);

}

Serial.println(“.”);

accel_x_OC=x;

accel_y_OC=y;

accel_z_OC=z-(float)g*1000/accel_scale_fact;

Serial.print(“Accel_x register offset = “);

Serial.println(x);

Serial.print(“Accel_y register offect = “);

Serial.println(y);

Serial.print(“Accel_z register offset = “);

Serial.println(z);

}

Telemetry Custom Commands

| /*

* Telemetry and Custom Command Sample Arduino Code * Telemetry Example: Monitor an extended I/O register value and send to control panel display * Command Example: Add Robot unique MOVE, BLINK, and SERVO commands */

#include <Robot3DoTBoard.h> // instantiated as Robot3DoT at end of class header

#include <EEPROM.h> //#include <Wire.h> // I2C support #include <Servo.h> #include <I2C.h>

// IMU Variables

#include “gyro_accel.h” // Defining constants #define IMUdt 20 // time difference in milli seconds #define rad2degree 57.3 // Radian to degree conversion #define Filter_gain 0.95 // e.g. angle = angle_gyro*Filter_gain + angle_accel*(1-Filter_gain)

// ********************************************************************* // Global IMU Variables // ********************************************************************* unsigned long IMUt=0; // Time Variables float angle_x_gyro=0,angle_y_gyro=0,angle_z_gyro=0,angle_x_accel=0,angle_y_accel=0,angle_z_accel=0,angle_x=0,angle_y=0,angle_z=0; // *********************************************************************

// Motor Variables

int Motor1F = 5; int Motor1R = 10; int Motor1PWM = A9; volatile int Motor1Speed = 0;

int Motor2F = 19; int Motor2R = 20; int Motor2PWM = 6; volatile int Motor2Speed = 0;

volatile int Mot1State = 0; volatile int Mot2State = 0; long HoldTime = micros();

// Servo Variables

//

Robot3DoTBoard Robot3DoT; // instantiated as Robot3DoT at end of class header

/* * Command Example * Step 1: Assign new command mnemonics ID numbers * In our example we will be adding 3 custom commands (2 new and one predefined). * The predefined MOVE command is intercepted and our robot unique code is to be * run instead. The MOVE command mnemonic ID 0x01 is already defined in Configure.h * The next two commands are new and assigned to the first two addresses in the * custom command address space 0x40 – 0x5F. */

#define DYNSTAT 0x41 const uint8_t CMD_LIST_SIZE = 2; // we are adding 3 commands (MOVE, BLINK, SERVO)

/* * Command Example * Step 2: Register commands by linking IDs to their corresponding command handlers * In our example when the MOVE command is intercepted the moveHandler is to be run. * In a similar fashion the BLINK command calls the blinkHandler and SERVO the * servoHandler. */

void moveHandler (uint8_t cmd, uint8_t param[], uint8_t n); void dynstatHandler (uint8_t cmd, uint8_t param[], uint8_t n);

Robot3DoTBoard::cmdFunc_t onCommand[CMD_LIST_SIZE] = {{MOVE,moveHandler}, {DYNSTAT,dynstatHandler}};

/* * Telemetry Example * Step 1: Instantiate packet * In our example we simulate a current sensor wired to MOTOR 2. MOTOR2_CURRENT_ID * is defined as 0x02 in Configure.h * To simulate the data stream coming from the sensor we will read ATmega32U4 * Register OCR4D which controls the duty cycle of MOTOR 2. */ Packet motorPWM(MOTOR2_CURRENT_ID); // initialize the packet properties to default values

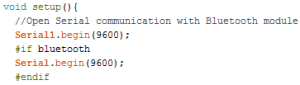

void setup() { Serial.begin(38400); // default = 115200

Robot3DoT.begin();

// Initialize Motor To Off

pinMode(Motor1F, OUTPUT); pinMode(Motor1R, OUTPUT); pinMode(Motor1PWM, OUTPUT);

pinMode(Motor2F, OUTPUT); pinMode(Motor2R, OUTPUT); pinMode(Motor2PWM, OUTPUT);

digitalWrite(Motor1F,LOW); digitalWrite(Motor1R,LOW);

digitalWrite(Motor2F,LOW); digitalWrite(Motor2R,LOW);

// Initialize IMU

Serial.begin(9600); I2c.begin(); I2c.timeOut(100); MPU6050_ResetWake(); MPU6050_SetGains(0,1);// Setting the lows scale MPU6050_SetDLPF(0); // Setting the DLPF to inf Bandwidth for calibration MPU6050_OffsetCal(); MPU6050_SetDLPF(6); // Setting the DLPF to lowest Bandwidth IMUt=millis();

/* * Command Example * Step 3: Tell 3DoT Robot software about new commands * * */

Robot3DoT.setOnCommand(onCommand, CMD_LIST_SIZE);

/* Telemetry Example * Step 2: Modify default values assigned to internal properties as needed. * Before a packet is created and sent, it is qualified. Specifically, * the data in a packet must change by some amount from the previous * packet and may not be sent with at a period less than some value. * In most cases you can leave these values at their default values. */ delay(1000); }

void loop() { Robot3DoT.loop(); // Set Motor State to the Telemetry Read Value

if (Mot1State == 1){ digitalWrite(Motor1F,HIGH); digitalWrite(Motor1R,LOW); } else if (Mot1State == 2) { digitalWrite(Motor1F,LOW); digitalWrite(Motor1R,HIGH); } else {digitalWrite(Motor1F,LOW); digitalWrite(Motor1R,LOW);}

if (Mot2State == 1){ digitalWrite(Motor2F,HIGH); digitalWrite(Motor2R,LOW); } else if (Mot2State == 2) { digitalWrite(Motor2F,LOW); digitalWrite(Motor2R,HIGH); } else {digitalWrite(Motor2F,LOW); digitalWrite(Motor2R,LOW);}

analogWrite(Motor1PWM, Motor1Speed); analogWrite(Motor2PWM, Motor2Speed); if (micros() – HoldTime > 500000){ HoldTime = micros(); // Serial.write(“”); // Serial.write(Mot1State); // Serial.write(Motor1Speed); // Serial.write(Mot2State); // Serial.write(Motor2Speed); // Serial.write(“”);

Serial.print(angle_x); Serial.print(“\t”); Serial.print(angle_y); Serial.print(“\t”); Serial.print(angle_z); Serial.println(); } // Read IMU Settings

//if (millis() – IMUt > IMUdt){ IMU(); //}

// Set Servos to IMU Setting

}

/* * Command Example * Step 4: Write command handlers */

/* * User Defined Command BLINK (0x40) Example * A5 01 40 E4 */

/* * Override MOVE (0x01) Command Example * A5 05 01 01 80 01 80 A1 */ void moveHandler (uint8_t cmd, uint8_t param[], uint8_t n) { Mot1State = param[0]; Mot2State = param[2];

// Configure Inputs and Output

Motor1Speed = param[1]; Motor2Speed = param[3]; Serial.write(cmd); // move command = 0x01 Serial.write(n); // number of param = 4 for (int i=0;i<n;i++) // param = 01 80 01 80 { Serial.write (param[i]); }

} // moveHandler

/* * User Defined Command SERVO (0x41) Example * Rotate servo to 90 degrees * A5 02 41 90 76 */ void dynstatHandler (uint8_t cmd, uint8_t param[], uint8_t n) { Serial.write(cmd); // servo command = 0x41 Serial.write(n); // number of param = 1 for (int i=0;i<n;i++) // param = 90 degrees { Serial.write (param[i]); }

} // servoHandler

void IMU(){ IMUt=millis();

MPU6050_ReadData();

angle_x_gyro = (gyro_x_scalled*((float)IMUdt/1000)+angle_x); angle_y_gyro = (gyro_y_scalled*((float)IMUdt/1000)+angle_y); angle_z_gyro = (gyro_z_scalled*((float)IMUdt/1000)+angle_z);

angle_z_accel = atan(accel_z_scalled/(sqrt(accel_y_scalled*accel_y_scalled+accel_x_scalled*accel_x_scalled)))*(float)rad2degree; angle_y_accel = -atan(accel_y_scalled/(sqrt(accel_y_scalled*accel_y_scalled+accel_z_scalled*accel_z_scalled)))*(float)rad2degree; angle_x_accel = atan(accel_x_scalled/(sqrt(accel_x_scalled*accel_x_scalled+accel_z_scalled*accel_z_scalled)))*(float)rad2degree;

angle_x = Filter_gain*angle_x_gyro+(1-Filter_gain)*angle_x_accel; angle_y = Filter_gain*angle_y_gyro+(1-Filter_gain)*angle_y_accel; angle_z = Filter_gain*angle_z_gyro+(1-Filter_gain)*angle_z_accel;

// Serial.print(gyro_x_scalled); // Serial.print(“\t”); // Serial.print(gyro_y_scalled); // Serial.print(“\t”); // Serial.print(gyro_z_scalled); // Serial.print(“\t”); // // // Serial.print(accel_x_scalled); // Serial.print(“\t”); // Serial.print(accel_y_scalled); // Serial.print(“\t”); // Serial.print(accel_z_scalled); // Serial.print(“\t”); // // Serial.print(angle_x_gyro); // Serial.print(“\t”); // Serial.print(angle_y_gyro); // Serial.print(“\t”); // Serial.print(angle_z_gyro); // Serial.print(“\t”); // // Serial.print(angle_x_accel); // Serial.print(“\t”); // Serial.print(angle_y_accel); // Serial.print(“\t”); // Serial.print(angle_z_accel); // Serial.print(“\t”);

// Serial.print(angle_x); // Serial.print(“\t”); // Serial.print(angle_y); // Serial.print(“\t”); // Serial.print(angle_z); // Serial.println();

// Serial.println(((float)(millis()-IMUt)/(float)IMUdt)*100); } |

Modified gyro_accel.cpp:

| /* Author = helscream (Omer Ikram ul Haq)

Last edit date = 2014-10-08 Website: http://hobbylogs.me.pn/?p=47 Location: Pakistan Ver: 0.1 beta — Start Ver: 0.2 beta — Bug fixed for calculating “angle_y_accel” and “angle_x_accel” in “Gyro_header.ino” file */

#include <Arduino.h> #include <Wire.h> #include “gyro_accel.h” #include “I2C.h”

// Defining the important registers

#define MPU6050_address 0x68

// —— SELF Test Trim Factors ———————- #define MPU6050_self_test_x 13 // R/W #define MPU6050_self_test_y 14 // R/W #define MPU6050_self_test_z 15 // R/W #define MPU6050_self_test_A 16 // R/W

// —– Sample Divider ——————————- #define MPU6050_sample_div 25 // R/W /* Sample Divider Discription Sample rate = 8/(1 + Sample rate divider) [kHz] if DLPF is disabled Sample rate = 1/(1 + Sample rate divider) [kHz] if DLPF is enabled */

// —– Configration ——————————— #define MPU6050_config 26 // R/W #define MPU6050_gyro_config 27 // R/W #define MPU6050_accel_config 28 // R/W

// —– Data ——————————————— #define MPU6050_data_start 59 #define read_bytes 14

// —– Power Management ——————————— #define MPU6050_PWR1 107 #define MPU6050_PWR2 108

// —– Defining Constant ——————————– #define g 9.81 // Gravitational accelration

// Variables int temp=0, accel_x=0, accel_y=0, accel_z=0, gyro_x=0, gyro_y=0, gyro_z=0; // Raw values varaibles int accel_x_OC=0, accel_y_OC=0, accel_z_OC=0, gyro_x_OC=0 ,gyro_y_OC=0, gyro_z_OC=0; // offset variables float temp_scalled,accel_x_scalled,accel_y_scalled,accel_z_scalled,gyro_x_scalled,gyro_y_scalled,gyro_z_scalled; //Scalled Data varaibles float accel_scale_fact = 1, gyro_scale_fact = 1; // Scale factor variables

// ************************************************************************** // Functions for MPU6050 // **************************************************************************

void MPU6050_ReadData(){

//Wire.beginTransmission(MPU6050_address); //Wire.write(MPU6050_data_start); //Wire.endTransmission();

I2c.write(MPU6050_address, MPU6050_data_start);

//int read_bytes = 14;

//Wire.requestFrom(MPU6050_address,read_bytes); I2c.read(MPU6050_address,read_bytes);

if(I2c.available() == read_bytes){

accel_x = I2c.receive()<<8 | I2c.receive(); accel_y = I2c.receive()<<8 | I2c.receive(); accel_z = I2c.receive()<<8 | I2c.receive();

temp = I2c.receive()<<8 | I2c.receive();

gyro_x = I2c.receive()<<8 | I2c.receive(); gyro_y = I2c.receive()<<8 | I2c.receive(); gyro_z = I2c.receive()<<8 | I2c.receive();

}

/* if(Wire.available() == read_bytes){

accel_x = Wire.read()<<8 | Wire.read(); accel_y = Wire.read()<<8 | Wire.read(); accel_z = Wire.read()<<8 | Wire.read();

temp = Wire.read()<<8 | Wire.read();

gyro_x = Wire.read()<<8 | Wire.read(); gyro_y = Wire.read()<<8 | Wire.read(); gyro_z = Wire.read()<<8 | Wire.read();

} */

accel_x_scalled = (float)(accel_x-accel_x_OC)*accel_scale_fact/1000; // divided by 1000 as the Scale factor is in milli units accel_y_scalled = (float)(accel_y-accel_y_OC)*accel_scale_fact/1000; accel_z_scalled = (float)(accel_z-accel_z_OC)*accel_scale_fact/1000;

gyro_x_scalled = (float)(gyro_x-gyro_x_OC)*gyro_scale_fact/1000; gyro_y_scalled = (float)(gyro_y-gyro_y_OC)*gyro_scale_fact/1000; gyro_z_scalled = ((float)(gyro_z-gyro_z_OC)*gyro_scale_fact/1000);

temp_scalled = (float)temp/340+36.53; }

// ———————————————— // Reset and wake up the MPU6050 // ———————————————— void MPU6050_ResetWake(){

Serial.println(“Resetting MPU6050 and waking it up…..”); Wire.beginTransmission(MPU6050_address); Wire.write(MPU6050_PWR1); Wire.write(0b10000000); Wire.endTransmission();

delay(100); // Waiting for the reset to complete

Wire.beginTransmission(MPU6050_address); Wire.write(MPU6050_PWR1);

Wire.write(0b00000000); Wire.endTransmission();

}

// ———————————————— // Setting up the DLFP // ————————————————

void MPU6050_SetDLPF(int BW) { if (BW < 0 || BW > 6){ BW = 0; } Wire.beginTransmission(MPU6050_address); Wire.write(MPU6050_config); // Address to the configuration register /* config Discription —- x x 0 0 0 F2 F1 F0 I am only intrested in the Digital Low Pass Filter (DLPF) F2 F1 F0 Bandwidth [Hz] 0 0 0 0 0 1 184 0 1 0 94 0 1 1 44 1 0 0 21 1 0 1 10 1 1 0 5 */

Wire.write(BW); Wire.endTransmission(); }

// ———————————————— // Setting up the Accelrometer and Gyro Gains // ————————————————

void MPU6050_SetGains(int gyro,int accel) { byte gyro_byte,accel_byte;

// Setting up Gyro Wire.beginTransmission(MPU6050_address); Wire.write(MPU6050_gyro_config); // Address to the configuration register if (gyro==0) { gyro_scale_fact =(float)250*0.0305; // each data is of 16 bits that means, 250 is divided along 2^(15)-1 = 32767 so for milli degree/s 0.0305 = 1000/32767 gyro_byte = 0b00000000; }else if (gyro == 1) { gyro_scale_fact = 500*0.0305; // each data is of 16 bits that means, 500 is divided along 2^(15)-1 = 32767 so for milli degree/s 0.0305 = 1000/32767 gyro_byte = 0b00001000; }else if (gyro == 2) { gyro_scale_fact = 1000*0.0305;// each data is of 16 bits that means, 1000 is divided along 2^(15)-1 = 32767 so for milli degree/s 0.0305 = 1000/32767 gyro_byte = 0b00010000; }else if (gyro == 3) { gyro_scale_fact = 2000*0.0305; // each data is of 16 bits that means, 2000 is divided along 2^(15)-1 = 32767 so for milli degree/s 0.0305 = 1000/32767 gyro_byte = 0b00011000; }else { gyro_scale_fact = 1; }

Wire.write(gyro_byte); Wire.endTransmission(); Serial.print(“The gyro scale is set to “); Serial.print(gyro_scale_fact); Serial.println(” milli Degree/s”);

// Setting up Accel Wire.beginTransmission(MPU6050_address); Wire.write(MPU6050_accel_config); // Address to the configuration register if (accel==0) { accel_scale_fact =(float)2*g*0.0305; // each data is of 16 bits that means, 2g is divided along 2^(15)-1 = 32767 so for milli m/s^2 0.0305 = 1000/32767 accel_byte = 0b00000000; }else if (accel == 1) { accel_scale_fact = 4*g*0.0305; // each data is of 16 bits that means, 4g is divided along 2^(15)-1 = 32767 so for milli m/s^2 0.0305 = 1000/32767 accel_byte = 0b00001000; }else if (accel == 2) { accel_scale_fact = 8*g*0.0305;// each data is of 16 bits that means, 8g is divided along 2^(15)-1 = 32767 so for milli m/s^2 0.0305 = 1000/32767 accel_byte = 0b00010000; }else if (accel == 3) { accel_scale_fact = 16*g*0.0305; // each data is of 16 bits that means, 16g is divided along 2^(15)-1 = 32767 so for milli m/s^2 0.0305 = 1000/32767 accel_byte = 0b00011000; }else { accel_scale_fact = 1; }

Wire.write(accel_byte); Wire.endTransmission(); Serial.print(“The accel scale is set to “); Serial.print(accel_scale_fact); Serial.println(” milli m/s^2″);

}

// ———————————————— // offset calibration // ————————————————

void MPU6050_OffsetCal(){ Serial.println(“Calibrating gyroscope …. dont move the hardware ……….”);

int x=0,y=0,z=0,i;

MPU6050_ReadData(); MPU6050_ReadData();

// Gyro Offset Calculation x=gyro_x; y=gyro_y; z=gyro_z;

for (i=1;i<=1000;i++){ MPU6050_ReadData(); x=(x+gyro_x)/2; y=(y+gyro_y)/2; z=(z+gyro_z)/2; Serial.print(“.”); } Serial.println(“.”); gyro_x_OC=x; gyro_y_OC=y; gyro_z_OC=z;

Serial.print(“gyro_x register offset = “); Serial.println(x);

Serial.print(“gyro_y register offect = “); Serial.println(y);

Serial.print(“gyro_z register offset = “); Serial.println(z);

// Accel Offset Calculation Serial.println(“Calibrating accelrometer …. dont move the hardware ……….”); x=accel_x; y=accel_y; z=accel_z;

for (i=1;i<=1000;i++){ MPU6050_ReadData(); x=(x+accel_x)/2; y=(y+accel_y)/2; z=(z+accel_z)/2; Serial.print(“.”); } Serial.println(“.”); accel_x_OC=x; accel_y_OC=y; accel_z_OC=z-(float)g*1000/accel_scale_fact;

Serial.print(“Accel_x register offset = “); Serial.println(x);

Serial.print(“Accel_y register offect = “); Serial.println(y);

Serial.print(“Accel_z register offset = “); Serial.println(z);

} |