By: Eduardo De La Cruz (Project Manager and Manufacturing Engineer)

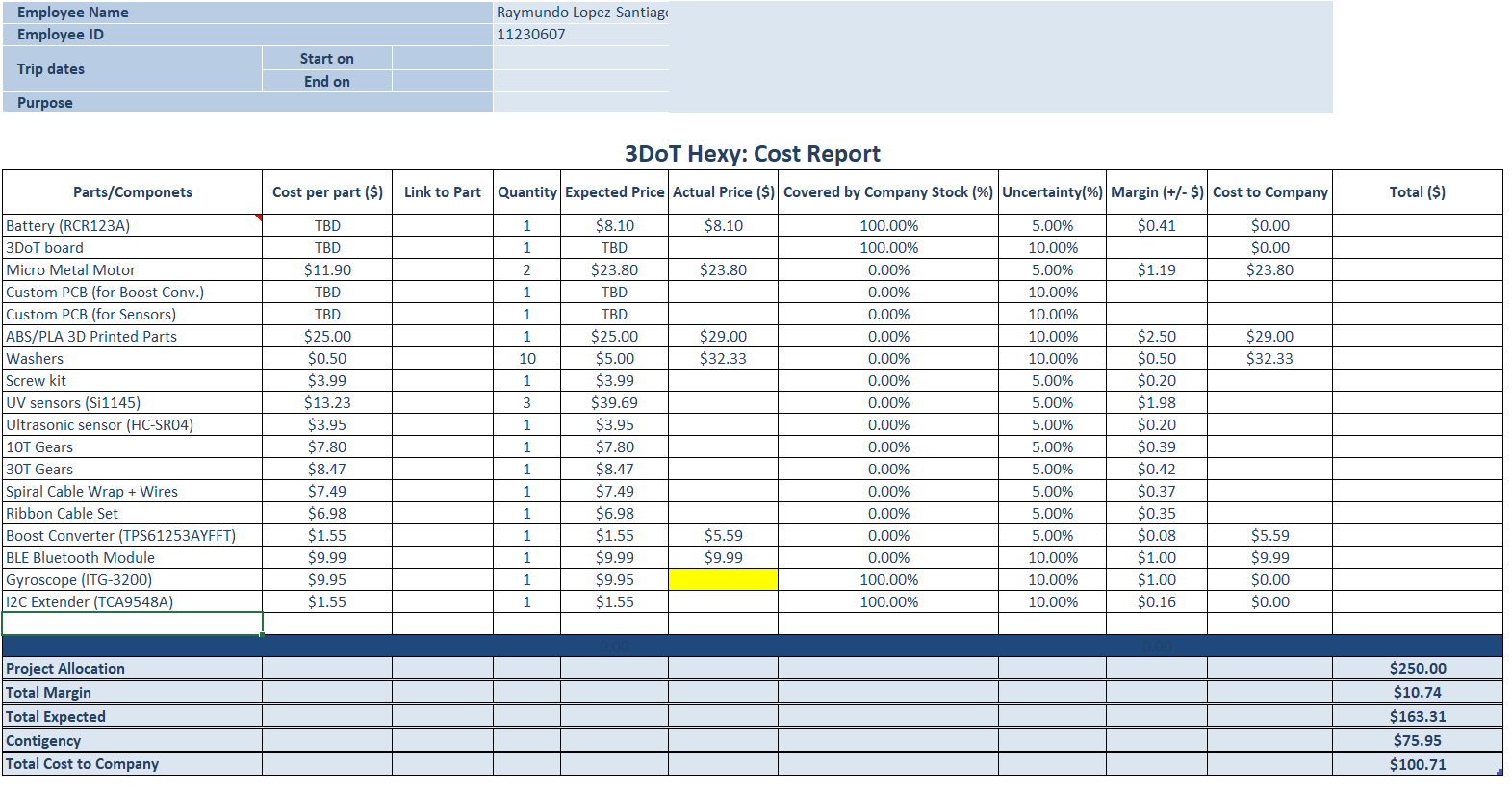

Approved by: Miguel Garcia (Quality Assurance)

The purpose of this blog post is to demonstrate how all parts designed in Solidworks needed to be modified to have a functional prototype. In doing this blog post, we learned that different materials function better than other materials in certain situations. Specifically, in parts that experience a lot of movement and contact with adjacent parts.

Level 1 Requirement

- In order to minimize manufacturing cost, and packaging cost the robot shall be able to be constructed from subassemblies within 10 minutes.

- The robot shall incorporate 3D printed parts to demonstrate the feasibility of the 3DoT board for 3D printed robots.

Improving Prototype Design (May 07, 2018)

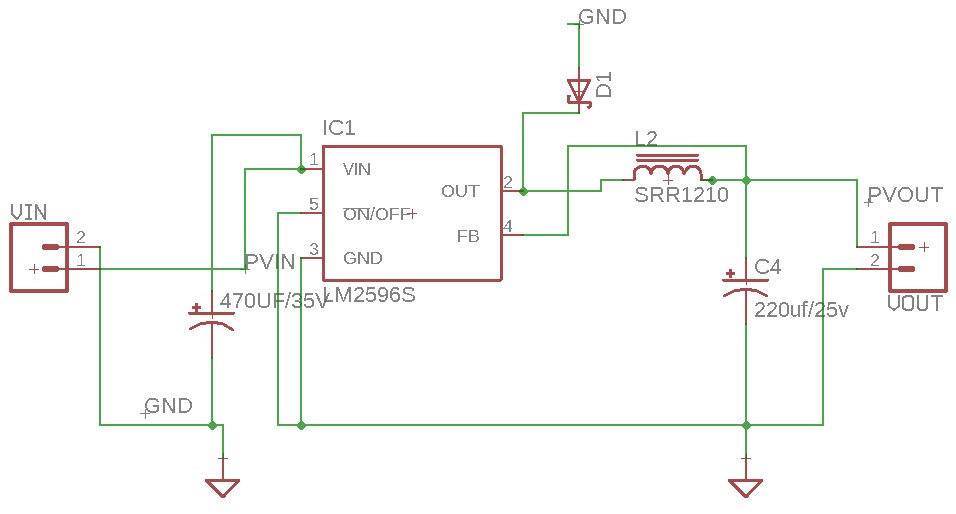

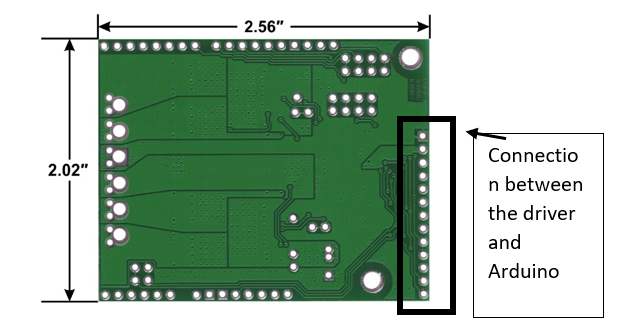

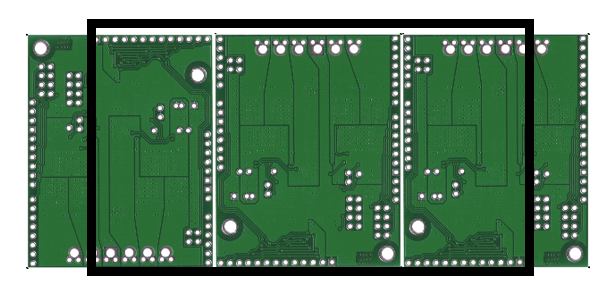

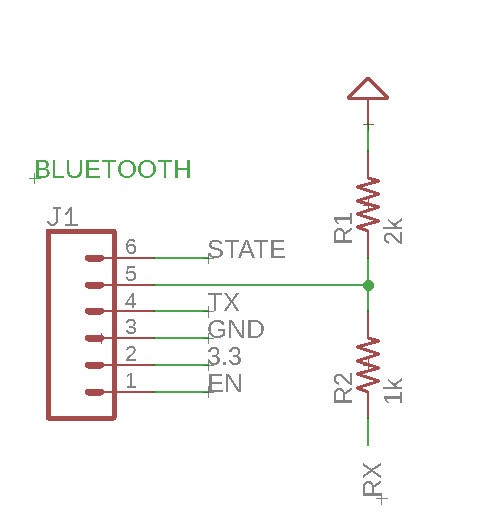

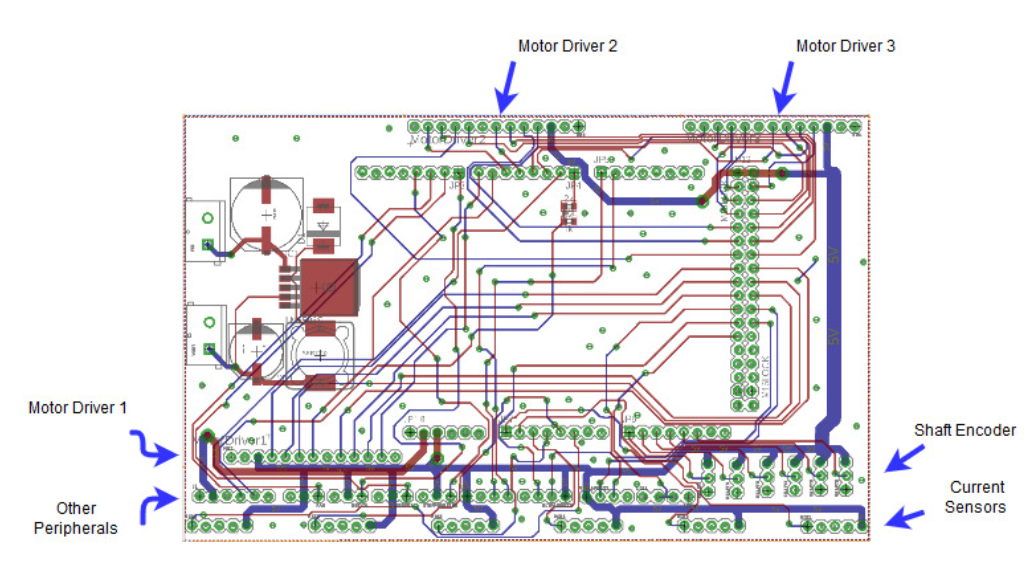

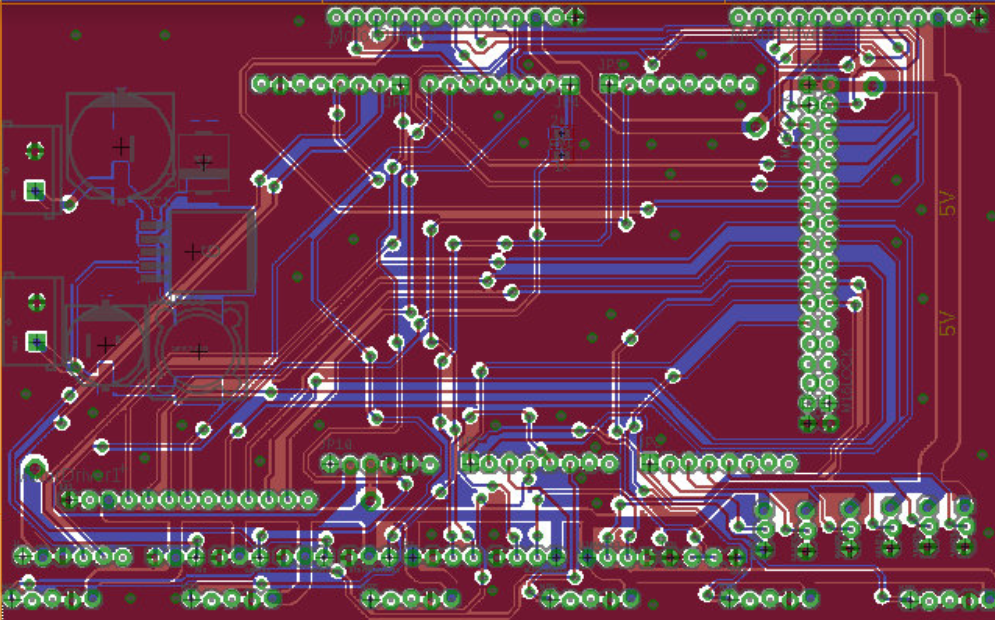

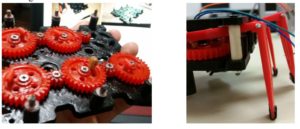

After designing and testing our prototype, we saw that there were many areas that we could improve upon to make our design better. Areas such as the gear holding system and our gear-to-femur joints needed to be re-evaluated due to customer concerns with the prototypes design. Among other things, we also saw that most testing with the prototype was done flawlessly between 4.5 to 5V. However, due to the unavailability of the booster shield due to design constraints discussed in “Spring 2018 3DoT Hexy: Booster Shield Layout” . We will have to operate 3DoT Hexy at the battery rating of 3.7V. In order to achieve the same performance we were getting at 4.5-5V with 3.7V we will have to re-evaluate our current design and minimize friction between moving parts as much as possible. The professor had multiple ideas to make this possible, as well as other ideas to make our design better. Among them, the most promising ideas were to add bearings into the gear shafts, and add bushings to the gear-to-femur joints. Below are implementations of these suggestions, as well as other solutions we came up with to improve the performance of our design.

Modifications to our Cam System

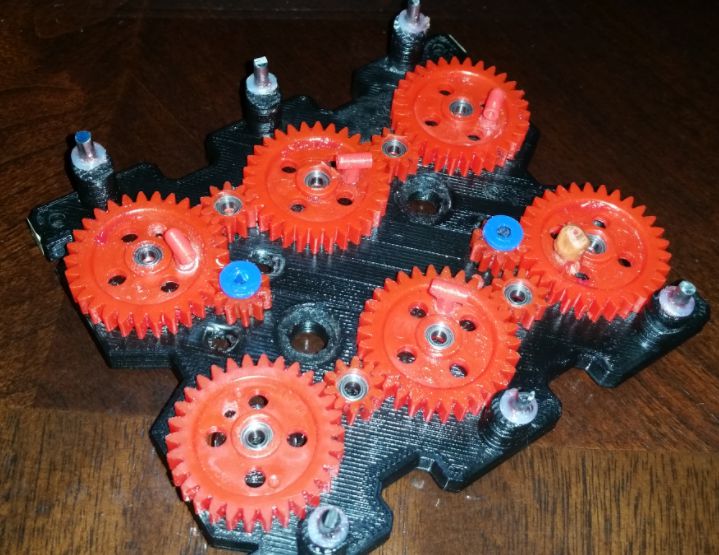

In order to improve our gear design’s performance at 3.7 V we decided to integrate bearings into the bores of our gear. This should improve performance while at the same time addressing one of the customers concern over the current machine screw design. The main issue addressed by the customer, was bore warping in the gears due to the machine screw thread being in contact with the plastic gear bore. We decided to integrate 3 mm x 6 mm x 2.5 mm bearings to the gear bores, which we outsourced from VxB bearings.

Figure 1: 3 x 6 x 2.5 mm bearings

How we did it

The bearing’s outer diameter was bigger than the bore diameter of the gears, so what we did was use a drill press to resize the bore holes. For better fitment, drilled boreholes were sized to the outer diameter of the bearings and forced in using a plastic hammer. We did this for all the gears.

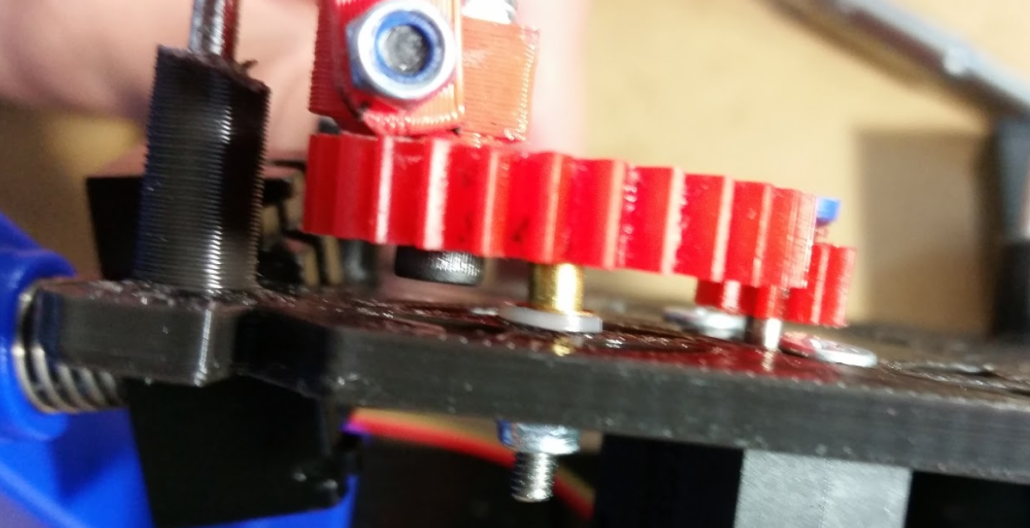

Figure 2: Installing bearings to gears

Figure 2: Installing bearings to gears

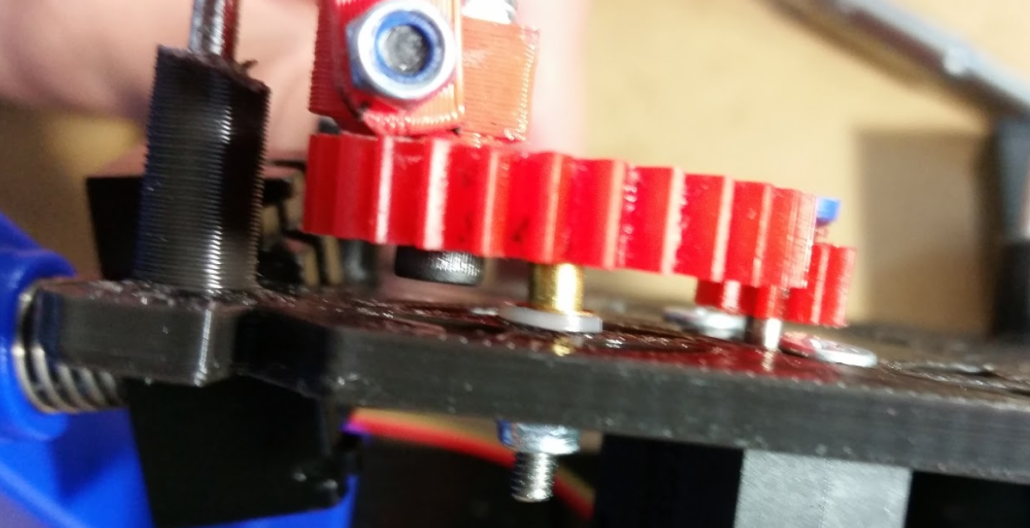

The gears were attached to the chassis of our spider using 16mm flat head machine screws, brass bushings, washers, and nylon lock nuts.

Figure 3: Gear Assembly

Figure 4: Gear Assembly

From the above figure, we can see that the brass bushing is used to pinch the bearing’s inner ring allowing only the outer ring to rotate.

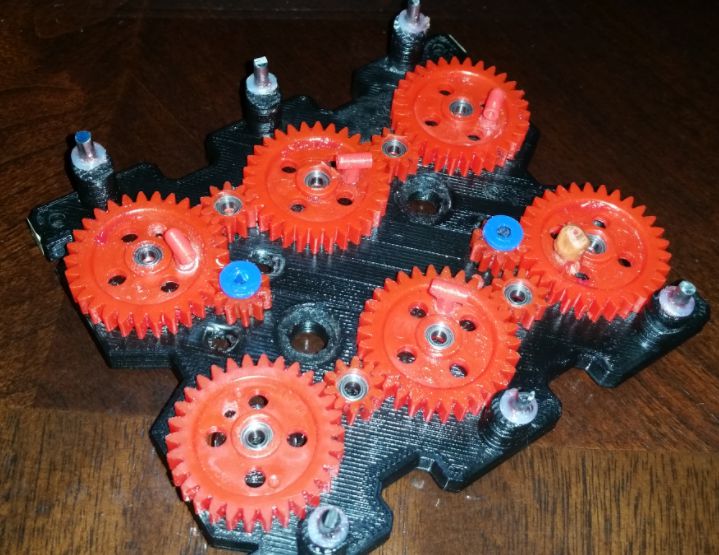

Figure 5: All bearings installed

Figure 5: All bearings installed

Modifying our Gear-to-Femur Joints

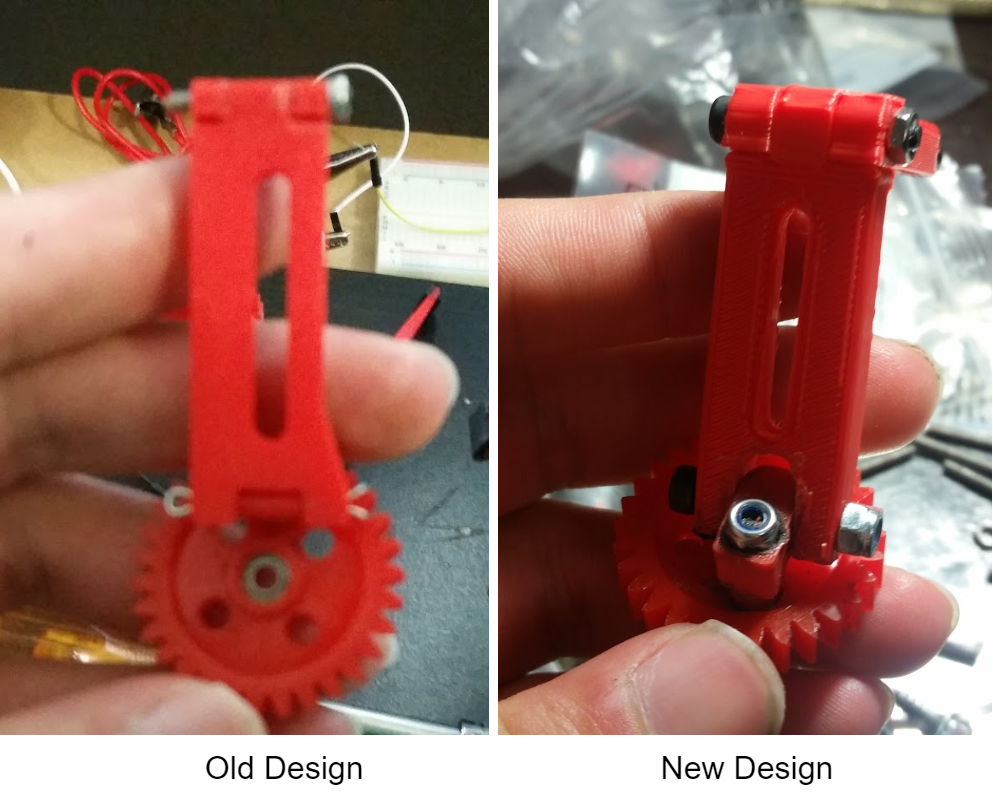

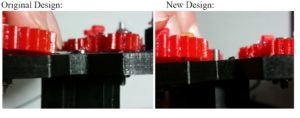

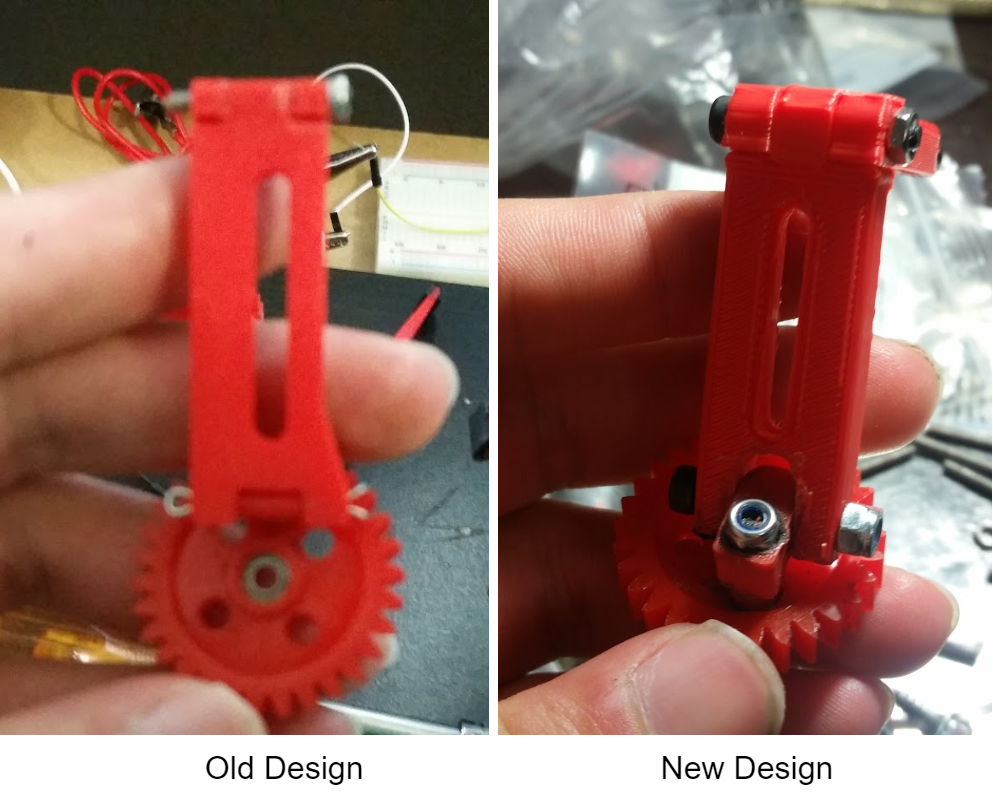

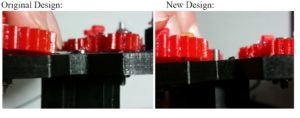

The gear-to-femur joint design in our prototype was very flimsy due to having too much play. This play was coming from using cotter pins and from using screws to hold the joint to the gear. A solution the professor had was to add bushing to the holes and run machine screws and lock nuts to make a more sturdy joint. Manufacturing decided to pursue this solution because implementing this design solution would enables us to control the amount of play required to run our robot at 3.7 V. Nevertheless, implementing this solution requires redesigning the joint as shown below.

Figure 6: Old vs New Joint Design

Figure 6: Old vs New Joint Design

Figure 7: Closer look at old vs new joint

Dimensions for the new joints can be found by clicking here.

As can be seen above, the new design will have individual holes to provide the 2 degrees of freedom required by our design. Very small aluminum bushings were inserted into these joints. As advised by the professor, Mcmaster carr was the best place to go to find these bushings. However, due to being unable to find the desired specifications for the inner and outer diameter for the bushings (3 mm ID, 4mm OD), time and cost. The manufacturing department decided to make them himself since he has had experience in the past shaping metal. Using an aluminum sheet, the manufacturing engineer was able to make aluminum bushings that would fit into the hole of the joints within a few hours for testing.

Figure 8: Making Aluminum Bushings

Figure 8: Making Aluminum Bushings

As shown above, making aluminum bushing is pretty easy, if you have the right tools. First,cut a piece of aluminum to the required perimeter length (C=2*pi*r). Second, shape the small sheet of aluminum into a tube using an aluminum rod and pliers. Three, cut excess material using wire cutting pliers or a dremel (if you have access to one). Sand and polish the tubes to remove all dents and to smooth the material.

Below is the final assembly of our new design. As can be seen the design looks more sturdy than our old design, because it is. The new joints are definitely much less flimsy than the old design, and can be adjusted by tuning the cap screws to the amount of play desired for best performance.

Figure 9: Final Assembly

Figure 9: Final Assembly

Prototype Part Adjustments/Modifications (April 05, 2018)

All components mentioned in our 3D model blog post, for Hexy Mk-01, were fabricated using a 3D printer. Parts that needed to be modified were fixed using a power drill and a Dremel tool for: cutting, grinding, sanding, and shaping the material.

Figure 10: Power tools used

Figure 10: Power tools used

Bottom Plate

Removed all shafts

We removed all shafts from the bottom plate design because 3D printed. 3 mm shafts were very thin and fragile. The manufacturing engineer would have to constantly glue on the broken shaft pieces. A better solution for this is making 3 mm holes at the shaft positions and inserting 3 mm stainless steel rods for the leg guides. Similarly, gear holder shaft were replaced with 3 mm holes and will insert machine screws and nuts to hold the gears down. We also increased diameter of the wire holes by 2 mm using a dremel tool. Therefore, in the Solidworks file revision, all shaft extrusions will be converted to holes.

Figure 11: Replacing all shafts with holes

Added spacers to the base of all the leg shafts

This was done in order to raise the overall height at which the legs would rise.

Figure 12: Added white spacers to shafts

Made holes for motors on the underside of the bottom plate

3 mm holes for motor boxes on the underside of bottom plate were added. This was done because the thickness of the bottom plate was preventing the motor shafts from having a good contact with the gears they connect too. Future revision of Solidwork files will require reducing the thickness of the bottom plate.

Figure 13: Adding holes to underside of bottom plate

Figure 14: Left – original shaft clearance, Right – new shaft clearance

Top Plate

Modified Resting holes for leg guide shafts

The resting holes for the leg guide shafts were too small, so we had to increase the diameter of them by approximately 1.5 mm using a dremel tool.

Figure 15: Modifying top plate holes

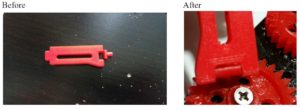

Femurs

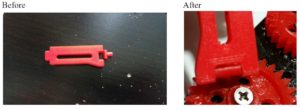

Sanded femur joint to tibia

Due to making the dimensions of the joint between femur and tibia the same size in both ends, mating the femur to the tibia was not possible. Therefore, the femur insert had to be sanded down using a dremel to enable the femur and tibia to mate correctly.

Figure 16: Before and after images of mating leg joint

Modified femur-to-gear joint junction

The edges on the underside of femur-to-gear joint junction were rounded. This was done because this end would tend to get stuck on the screw during rotation of the gear. We also increased the diameter of the hole to 2.5 mm in order to easily insert cotter pins

Figure 17: Modified femur edges and hole

Tibias

Adding grip

The tibia designed would bond easily to femurs after femur joint was modified. The only issue discovered was that the current design of having plastic tips would make Hexy susceptible to sliding while walking. Therefore, we decided to glue thin 10 mm x 5 mm x 2 mm pieces of rubber to the tips of the legs to increase the grip Hexy will have while walking.

Figure 18: Adding grip to tips

Sanded junction between gear joint and femur

The same issue we had with the femur-to-tibia junction came up with the femur to gear joint. The dimensions of both mating points were designed with the same measurements causing them to not fit together as they should. The solution was to sand down the junction between the joint and the femur for better fitment.

Figure 19: Adjusting gear joints for fitment

Added 2 mm holes on the gears in order to insert the screw that will hold the femur-to-gear joint in place.

Figure 20: Adding hole to gears

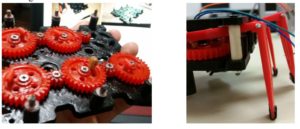

Testing Alternative gear-to-femur joint solutions

The current joint design was not very reliable. Do to the thin design of the borehole walls (where the screw is to be inserted), the joint would split open when a screw would be inserted. Liquid glue had to be added to the joint to hold it in place. Two solutions proposed by the manufacturing department were to either: redesign the joint and 3D print one with thicker borehole wall, or make them out of more durable materials, such as wood. Below is an image of a wooden joint fabricated by the manufacturing engineer. We will attempt to redesign joints to look like the wooden sample which is thicker. We might even try 3D printing them for easy manufacturing. If 3D printing these joints doesn’t work we will make them out of wood.

Figure 21: Two types of gear-to-femur joints

Four 20 mm spacers were fabricated out of wood tubes for this prototype and will be replaced by nylon spacers in a future revision.

Figure 22: Wooden spacers

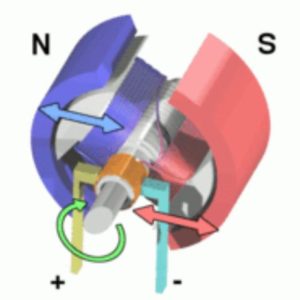

Our plan for making the connection between the 10T driving gears and the motor shaft is to do one of the following:

- Insert a bushing to 10T Ajax gears to compensate for the different bore diameter of the Ajax gears and the diameter of the gear shaft.

Figure 23: Method 1

Figure 23: Method 1

- Purchase 10T gears with a smaller bore diameter and shape a D that matches that of the gear motor shaft. This is done to lock the gear to the motor shaft while spinning.

Figure 24: Method 2

Figure 24: Method 2

Both designs have been built and tested. From the test we saw that both methods work the same and don’t differ in performance when driving the motion of the cam system. We will use method A due to having the same gear color as the rest of the cam system, as well as for providing the least amount of play when inserted to the motor shaft. We will use method B as a backup in case we have issue with method A later in the design.