Goliath Fall 2016

Post CDR Redesign

By: Dylan Hong (Design and Manufacturing Engineer)

Approved by Kristen Oduca (Project Manager)

Introuction

Requirement: The Goliath shall be a scale model of the Goliath 302 tank.

After the CDR presentation, we were able to implement our design with software and hardware integration. We combined the 3D printed model with the electronic components such as the motors, sensors, and breadboard to test out its functionalities. After testing, we realized that the design from CDR had to change in order to have the Goliath be more practical. The concerns when testing our model was that the suspension-like wheels that we printed for CDR was not sturdy enough and easy to assemble. Also, the smaller wheels were too thin and could not support the Goliath as a whole. Furthermore, while the brass hinges worked well, the customer did not like the appearance of it with the Goliath and desired that we make the sensor doors and top-bottom panel door incorporate its own plastic hinges.

Post CDR Redesign

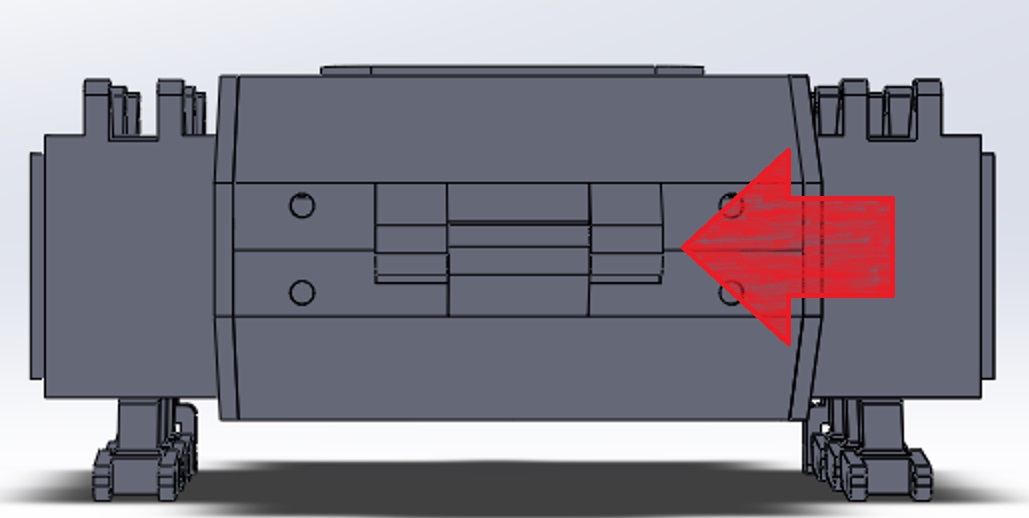

Since the small wheels were fragile and too difficult to assemble, we decided to make the wheel holders a part of the side panel instead of its own separate part. Originally, we planned on having the wheel holders carry two small wheels, but printing such small parts were not pratical. To make it thicker, we designed the wheel holder to look like caster wheels, which will hold a single small wheel instead of two. We also changed the dimensions of the small wheels from 2mm to 4mm so that we would have a better fit onto the tracks shown in Figure 1.

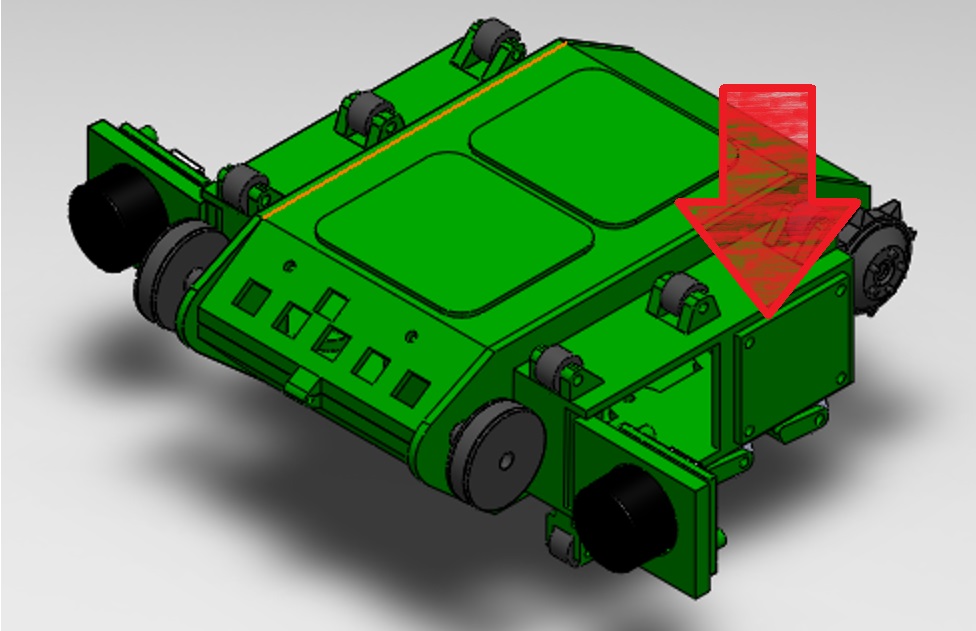

As for the hinges, we incorporated a plastic snap on hinge for the top-bottom panels and sensor doors to eliminate the appearance of the brass and to make the Goliath use less hardware fasteners such as screws and nuts shown in Figure 2 and 3.

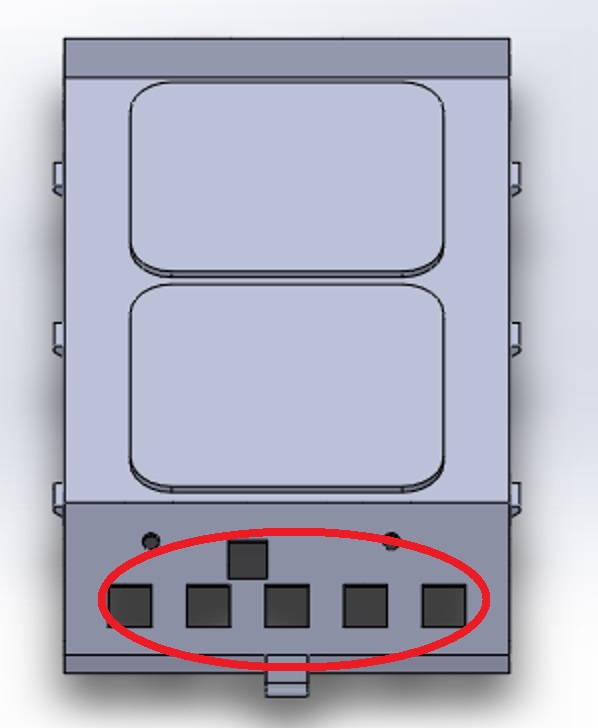

Also, since the PCB will be mounted underneath the top panel, we made cut outs of the SMD LEDs and trimmpot so that the LEDs can be visible to the audience and so the speaker volume can be adjustable shown in Figure 4.

Other details have been added for cosmetic purposes that relate to the 302 Goliath such as the screw holes for the side panel, the rear bar bumper and the pointed handle on the front of the Goliath shown in Figure 5.

Note that the details on the top panel such as screw holes were removed due to it interfering with the attachment of the suction cup, which is used to hold the LG G2 on top of the Goliath.

Conclusion

Overall, these little tweaks to the design were needed to fix the functionality of the wheels and tracks when in motion. The PCB cut out were also needed to display the distance and direction of the Bidped to the user and the audiences. The other minor changes were mainly cosmetic tweaks that linked to the requirement of making the model look as much as the 302 Goliath.