Spring 2016 A-TeChToP Central Sensor Suite PCB Layout

By Mimy Ho (Manufacturing Engineer)

Overview

The chest harness prototype of the central sensor suite will have the 3D printed case which contains a printed circuit board and a 9V battery. The PCB includes the Arduino Pro Mini, accelerometer, temperature sensors, ECG circuitry, pulse oximeter circuitry. The PCB supports and electrically connects all the sensors to the Arduino Pro Mini. The schematic and layout were generated by Eagle CAD software.

Table of Contents

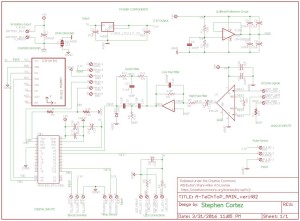

Schematic

The PCB schematic was received from the Stephen Cortez (Electronics Engineer).

Along with the schematic, there is a note from the Electronics team’s requirements for the layout. All the requirements must be put into consideration when designing the layout:

- AGND and DGND must be separate ground planes (separate on same layer), star connected to chassis ground (GND) and very close to the battery input connector. Star connection is accomplished with an SMD solder jumper SJ1.

- AGND is the analog ground associated with

- op amps (LM358)

- instrumentation amplifier (INA128)

- regulators (LM1117 — 3.3V version)

- pulse sensor (PULSE)

- DGND is the digital ground associated with

- Arduino Pro Micro

- Bluetooth unit (HM10)

- gyro/accelerometer (GY-521)

- blood oximeter (TSL235R)

- temperature sensor (DS18B20)

- AGND is the analog ground associated with

- Capacitor placement is critical

- C1 must be close to the battery input

- C2 and C3 must be close to the voltage regulator

- C5 and C7 must be very close to the LM358 power supply pins

- C9 must be very close to the INA128 power supply pins

- C16 should be close to the LED input connections

- C17 must be close to the Arduino power supply pins

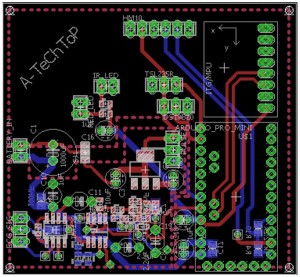

Layout

The board has 2 layers at 2.5 x 2.37 inches. M2 screw sizes are used for mounting. From the 9V battery to the voltage regulator and the Arduino Pro Mini, thick traces need to be used to make sure they will have enough current going through to power up the board.

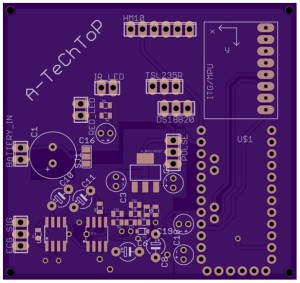

Manufacturing

Based on the recommend from the Manufacturing Division Manager, OSH Park was chosen as the PCB manufacturer. 3 boards were the minimum order from OSH Park and it cost about $30 for 3 boards. It took 12 business days for fabricating and 1-5 days for shipping. It will take around 3 weeks from the date that the file was sent to OSH Park to the date it arrives.

The components of the board will be ordered by the Project Manager from the Digikey website and from the Manufacturing Division Manager’s resource.

Top view of the board:

Bottom view of the board: