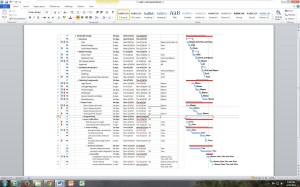

Completed schedule and test plans

By Mason Nguyen, Project Manager

In order to build a successful project, it is important that our team to develop an effective test plans and schedule to manage our assignments. Our test plans will be divided into four categories where each member is expected to perform and complete.

3D Model:

A hexapod model will be designed through our manufacturer Vinh Kim. He will be using Solid Works program to perform stress test, materials test and create initial 3D design for our hexapod. The timeline to complete his assignment is 7 weeks. Down below is Vinh’s roadmap break down.

3D Modeling: 1.5 Weeks

- Designing the Hexapod body, femur, tibia, and bracket using SolidWorks.

- Creating a prototype model of the Hexapod using cardboard, cable ties and tape.

Solid works and materials testing: 3.5 Weeks

- Doing a trade-off studies using Silicone Rubber vs. Urethane Rubber.

- Measuring the component and calculating the weight distribution.

- Using SolidWorks Simulation Xpress Study to test the materials and perform a stress test on the tibia and bracket.

Manufacturing: 2 Weeks

- 3D printing the Hexapod body parts.

- Molding the Hexapod body parts out of rubber.

- Casting the Hexapod parts using Urethane.

- Assembling the Hexapod.

Power:

To support the hexapod movements, servos will serve as the primary pillar for the hexapod to walk. Meanwhile, the battery will be the main component to power up the hexapod. To understand more about servos, several testing experiments will be conducted to test its functionality such as angle, rotation, current and torque. This assignment will be performed by the project manager and it will take 10 weeks to complete. Also components will be ordering based on the trade-off study from the servos and battery.

Servo testing and requirements: 3.5 Weeks

- Comparing servos (price , size and power)

- Trade-off study of servos

- Testing servos torque, angle and current drawn

Battery testing and requirements: 2.5 Weeks

- Comparing batteries (price, size and power)

- Testing power allocation of battery.

Ordering Supplies: 4 Weeks

Programming:

Programming will be the most difficult task due to many requirements of the servos angle and rotation. To complete this assignment, our team computer engineer Chau To will be given 10.2 weeks to run various tests and calculations. His roadmap is defined below.

Servo calibration testing: 2.5 Weeks

- Matching the angle swing of each servo in degrees (from 0 to 180 degrees).

- Calculate the delay time and servo’s angle for Hexapod movement.

Software testing: 8 Weeks

- Writing code for Hexapod movement including WALK, RESERVE, TURN LEFT, TURN RIGHT, PHONE CAMERA CONTROL functions.

- Implement and Trouble shooting.

- Link to Artexia Android Apps.

- Troubleshooting for entire system.

Communication:

Using an android phone, the hexapod will be controlled wirelessly from Arxterra interface. Tien Dang who’s our communication engineer will be responsible to perform the Arxterra coding and testing integration. His assignment is expected to complete within 8 weeks. He also will be helping out Tommy with Arxterra interface. His road map is defined below:

Arxterra testing requirements: 4 Weeks

- Learning about Arxterra new version of Arxterra.

- Installing the app on the Android phone.

Arxterra coding: 4 Weeks

- Testing Arxterra code.

- Arxterra phone compatability test.

- Linking Arxterra web page from laptop to the android.

As shown in the schedule, the team has performed and completed all of our tasks. Our final finishing touch will be demoing process and a short movie clip to wrap up our project.