Mold Case Study

By Vinh Kim, 3D Modeling and Manufacturing

Introduction:

Here I did a study on Silicone rubber (Mold Max 40 vs OOMOO 30) vs. Polyurethane rubber. The Mold Max 40 was the silicone rubber the fall 2013 Hexapod team used. I want to give our regards to Ramon Luquin (Fall 2013 Hexapod Project Manager) for donating his mold and casting material to our team.

Durability:

Here we want the rubber to be flexible as much as possible, so it does not break when bending. Therefore, we will take a look at the Elongation at Break and Tear Strength number from www.smooth-on.com.

The Elongation at Break is when the material breaks after it being pulled apart and the Tear Strength is the material that resistance to tearing. As shown in the Figure 1 and 2 that I am bending the rubber with my hand and it did not rip or pull apart.

Figure 1: Mold Max 40 Rubber

Figure 2: OOMOO 30 Rubber

| Product Name: | Elongation at Break | Tear Strength |

| Mold Max 40 | 250 % | 120 pli |

| OOMOO 30 | 250 % | 40 pli |

| Vytaflex 60 | 480 % | 136 pli |

Durability Winner:

- Vytaflex 60

- Mold Max 40

- OOMOO 30

Mixing Viscosity:

Here we will look at the viscosity. I noticed that if the viscosity has a very low Centipoise (CPS) number than it will flow really easy and does not need to be vacuum degassed when mixing. If it has a high CPS number, than it requires vacuum degassing to remove all the air when mixing because it does not flow easily which will create a lot of air bubble.

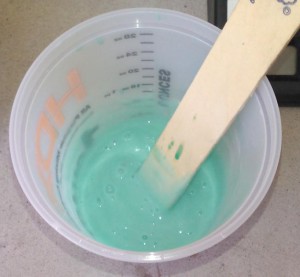

Figure 3: Mold Max 40 Mixing

Figure 4: OOMOO 30 Mixing

| Product Name: | Mixing Viscosity |

| Mold Max 40 | 45000 cps |

| OOMOO 30 | 4250 cps |

| Vytaflex 60 | 2000 cps |

Mixing Viscosity Winner:

- OOMOO 30

- Vytaflex 60

- Mold Max 40

What is a Shelf Life?

A shelf life is an unused product in a container that has been opened and exposed to the ambient moisture in the air.

For polyurethane rubber, from Smooth-on.com states, “Unused Part A product exposed to humidity will begin to turn from liquid to solid in as little in a few hours. Part A exposed to relatively low levels of humidity which will last two to three months in the container before showing signs of moisture contamination”.

For silicone rubber, Smooth-on.com states, “Properly stored at room temperature (73°F/ 23°C), silicone rubber will have a shelf life of 6 months from date of manufacture”.

Shelf Life Winner:

- Silicone rubber( Mold Max 40 and OOMOO 30)

- Polyurethane rubber( Vytaflex 60)

Cost:

Here we will look at the cost of the 1 gallon unit and the trial size. For our group, we did not need and use a lot of rubber, so we went with 2 trial size of OOMOO 30 to mold the body and the leg of the Hexapod.

| Product Name: | 1 Gallon Unit | Trial Size |

| Mold Max 40 | $96.54 | $25.47 |

| OOMOO 30 | $153.03 | $25.47 |

| Vytaflex 60 | $110.17 | $25.96 |

Cost for Trial Size Winner:

- Mold Max 40 and OOMOO 30

- Vytaflex 60

Cost for 1 Gallon Unit Winner:

- Mold Max 40

- Vytaflex 60

- OOMOO 30

Conclusion:

Overall, I think the OOMOO 30 is the best rubber to buy because of the trail size cost. Also the shelf life is so much better and last longer than the polyurethane rubber and it does not require vacuum degassing when mixing. Plus the durability is pretty good. I recommend when purchasing molding material, remember look for the durability, mixed viscosity, shelf life and cost.

References:

http://www.smooth-on.com/Silicone-Rubber-an/c2_1113_1135/index.html

http://www.smooth-on.com/Silicone-Rubber-an/c2_1113_1136/index.html

http://www.smooth-on.com/Urethane-Rubber-an/c6_1117_1142/index.html

http://www.smooth-on.com/faq_display.php?faq_id=99

http://www.smooth-on.com/Silicone-Rubber-an/c2_1113_1135/index.html?catdepth=1

http://www.smooth-on.com/Silicone-Rubber-an/c2_1113_1136/index.html?catdepth=1

http://www.smooth-on.com/Urethane-Rubber-an/c6_1117_1142/index.html?catdepth=1