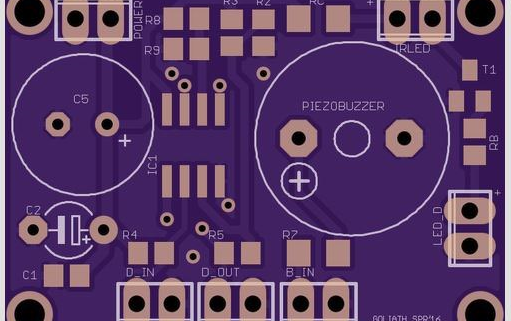

BY: Kent Hayes (Electronics and Control)

Introduction

A servo is an assembly of 4 different things: a DC motor, a gear-reduction unit, a position sensing unit, and negative feedback to control the motor’s speed/position. Unlike the DC motor, servos use a 3 wire connection for the power, ground, and control. The servo receives a control signal (PWM) that represents a desired position and powers the motor until its shaft reaches this desired position. They are typically able to rotate 200 degrees back and forth.

A DC motor uses only 2 wires, through which all of the power is supplied. The power level is controlled by PWM which is a ratio of the on time and the off time or the duty cycle. So if the power is on for half the time, then the motor operates with half of the power of its full-on operation. However there are various types of motors, so in the resources section you will see a link which has nice summaries of the different motors and which ones will be of the best use to the reader.

Types of Servos:

- RC Servos. The most common and economical type of servo motor that normally come with 180 degree range for rotation. You can drive these through servo controllers or through GPIO pins from a microcontroller. A major disadvantage of these is that there is no feed back to the program of which you use to control them, so one cannot be entirely sure that it is operating properly.

- Analog Feedback Servos. Come with an extra feedback wire that you can connect to an analog input pin in order to get feedback to the user’s program.

- Continuous Rotation Servo. They are “hacked” RC servos, meaning that the controller feedback is hard-wired to believe that it is always at a middle position, resulting in a reversible, speed controlled gear-motor. A disadvantage is that it can be difficult to find the neutral point in the control signal where the motor stops using all together.

Types of Motors:

- Brushed Motors. The most common type of motor because they are light, inexpensive, efficient, and have reasonable torque at low speeds. Can be used in toys, RC servos, and even gear motors.

- A gear-motor is a brushed motor with reduced speed but increased torque through the use of a gear-train. The reduction of speed is actually an advantage because most DC motors spin too fast. A disadvantage is with the extra resistance, the gear-trains will become unresponsive at lower voltages.

- Brushless Motors. Replaces the brushes with electronic communication to switch the current flow to drive the motor, while maintaining its efficiency. Typically used in laptops as fans and quadcopters. The main disadvantage is that it normally requires a separate controller for operation.

- Stepper Motors. DC motors that move is discrete steps so they have much more precise speed control. Another advantage includes having a reasonable low-speed torque. The main disadvantages include reduced efficiency and being subject to missing steps if overloaded.

Servo Trade-off Study Guiding Factors

The purpose of the servo was to control the rotation of the head, while the motors would control the movement of the legs. In choosing a servo, we would need it to rotate 360 degrees continuously within our voltage range of 3.7V to 5V. In addition, it should be lightweight, small in size, and inexpensive so that it not bring us over our budget. The following table are the results from what Kent was able to find online:

Motor Trade-off Study Guiding Factors

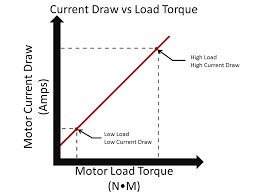

After reading about the different types of motors, I began to look at motors that would work for the 3DoT David team. The main factors that contributed to his search were the following: size, cost, and voltage rating. The size is important to our project since the mechanical design has been shrunk in size compared to previous generations of spider bots. Our budget for the project is not supposed to exceed $80.00 so it is best to be aware of how much each type of motor will cost. Finally, it is important to have a motor that can operate within 3.7V~ 5V since the 3DoT board will allow us to operate within this range. After searching online, the only motors that were able to fit our specifications were of the brushed motor type. All other stepper motors and brushless motors were either too large or had too high of a voltage rating. In addition, they both require separate controllers and are much more complicated to control.

Update:

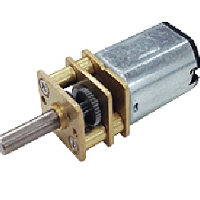

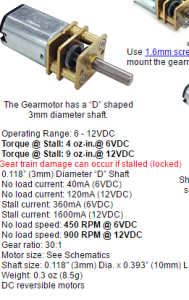

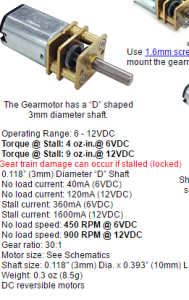

After our team team received new gears, we began testing to see if the motors would still be able to work. Unfortunately, they did not have enough torque to turn our gear train. Kent then began to test with the DC hobby motor, which did have enough torque but was too heavy and bulky to work with our design. He then turned to the E&C division manager for possible solutions and he recommended that we take a second look into geared motors.

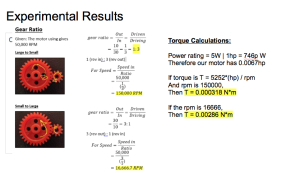

After looking online, Kent found a list of micro geared motors from the Servo City website. They had various motors from 45RPM to 2500RPM and as the speed increased the torque decreased. Therefore when searching, we had to make sure we had enough torque at a speed that would make our legs rotate at a reasonable rate. We agreed that 2 cycles/sec would be an appropriate speed to enable the spider to walk. In order to acheive this, hr did the following calculations:

2 cycles/sec * 60 sec/min = 120 cycles/min (RPM)

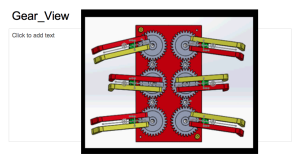

The gear ratio we are using is 3:1 so,

120 RPM * 3 = 360 RPM

So 360 RPM is the minimum speed we need motor to rotate in order for the micro geared motor to rotate our legs at 2 cycles/sec. Therefore we purchased 2 micro geared motor that have 450 RPM at 6V. We will not reach 6V due to our board only being able to supply 5V, so as the PWM signal gets closer to 5V we should be able to reach 360 RPM if not greater. Once they arrive, we can begin to test to see how reliable they are and if we will need to choose something else.

Trade-off Studies Tables

Servo-Trade Off Study

| Requirements Met |

Servo Name |

Price |

Torque

(kg)

|

Speed |

Voltage (V)

|

Weight

(g)

|

Dimensions |

| -Supply voltage is realizable since we can do anything between 3.7 and 5V. |

Single Cell 3.2g / .16kg / .10sec Digital Ultra-Micro Servo |

$7.95 |

.16 ~.19 |

.1s~.08 sec/60 degrees |

3 ~ 4.2 |

3.2 |

28mm x 9 mm x 22mm |

| -Supply voltage is realizable since we can do anything between 3.7 and 5V.

-Weighs less than 2 g |

Ultra Micro Servo 1.7g for 3D Flight |

$4.34 |

0.08 |

0.12 sec/60 degrees |

3.7 ~ 4.2 |

1.7 |

12 mm x 21 mm x 0mm |

| -Supply voltage is realizable since we can do anything between 3.7 and 5V.

– Affordable since it is less than $4.00

-Weighs less than 2 g |

HK-5330 Ultra-Micro Digital Servo 0.17kg / 0.04sec / 1.9g |

$3.64 |

.12 ~.17 |

.06~.04 sec/60 degrees |

2.8 ~ 4.2 |

1.9 |

20 mm x 6 mm x 23 mm |

| -Supply voltage is realizable since we can do anything between 3.7 and 5V.

-Affordable since it is $3.99

-Weighs about 2 g |

HK-282A Single-Screw, Ultra-Micro Servo 2g / 0.2kg / 0.08sec |

$3.99 |

0.2 |

0.08 sec/60 degrees |

3~4.8 |

2 |

23mm x 8mm x 20mm |

| -Can rotate 360 degrees |

Continuous Rotation Micro Servo FS90R |

$7.50 |

1.3~1.5 |

110~130 rpm |

4.8~6 |

10 |

32mm x 12mm x 30 |

| -Can rotate 360 degrees |

Continuous Rotation Servo – FeeTech FS5103R |

$11.95 |

3~3.2 |

.18sec/60 degrees |

4.8~6 |

40 |

37mm x 20mm x 54mm |

Motor Trade-Off Study

| Name |

Requirements Met |

Rated Volt |

Max Volt |

Min Volt |

No load Current |

Stall Current |

No Load RPM |

Power Rating |

Weight |

Size |

Price |

| DC Toy/ Hobby Motor |

Cost effective |

6V |

9V |

2V |

70mA |

500mA |

7300~10900 |

420 mW |

17.5 g |

27.5mm x 20mm x 15mm |

$1.95 |

| Hobby Motor |

-Cost effective |

3V |

12V |

1V |

110mA |

N/A |

6000~7200 |

330mW |

26g |

2.75cm x 2.75 cm |

$1.95 |

| 3.7V 50,000 RPM Small Colorless Motor 716 |

-Operational voltage is reachable.

-Cost Effective

-7mm diameter |

3.7V |

N/A |

N/A |

100mA |

1.35A |

50000 |

5W |

2.5g |

16.5 mm x 7mm |

$1.95 |

| FA-GM6-3V-25 Micro Motor Mini Motor |

-6mm diameter |

3V |

N/A |

N/A |

100mA |

N/A |

1200 |

300mW |

1.2g |

20 mm x 6mm |

$9.00 |

Conclusion

- Servos are excellent in terms of precision of control which is why we first considered using them for our robot.

- In addition, they have a great amount of torque for dealing with heavier loads.

- However, after looking into greater detail, we realized they might not be as useful to our project as we previously thought.

- They are much too bulky to fit inside the spider.

- Their price is quite unreasonable when being compared to the motors.

- Would only be able to get the CR servos(for the 360 degree rotation of the head)

- The 3.7V 50,000 RPM Small Colorless Motor 716 has more advantages for our application when compared to the rest of the available options.6

- Its rated voltage is realizable since our battery is going to be 3.7V,

- Max(stall) current is 1.5A which is excellent since our motor driver will might output 1A maximum

- It is only 2.5 grams

- Reasonably priced, $1.95

- Only disadvantage of this motor is that we do not know the torque specifications and will have to do my own calculations based on the information given. These calculations will be placed in a separate blog post if you wish to see them.

- Project Update

- The mechanical design of our 3DoT david changed in order to make the assembly much simpler than before, and will therefore not require us to use servos. The new design has it set where one motor will control the right side of the legs and the other will control the left side.

Resources:

https://learn.adafruit.com/adafruit-motor-selection-guide/types-of-motors

https://www.adafruit.com/products/711

https://www.sparkfun.com/products/11696

http://www.seeedstudio.com/depot/37V-50000RPM-Small-Coreless-Motor-716-p-1884.html

https://www.firgelliauto.com/products/mini-motor-micro-motor

https://www.servocity.com/html/micro_gearmotorblocks.html

http://www.hobbyking.com/hobbyking/store/index.asp

http://handyboard.com/hb/faq/hardware-faqs/dc-vs-servo/

https://learn.adafruit.com/adafruit-motor-selection-guide/continuous-rotation-servos

https://learn.adafruit.com/adafruit-motor-selection-guide/rc-servo-control