Height Requirement

By Maxwell Nguyen

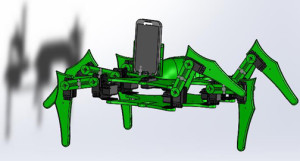

Along the designated course shared by the Rover, Spiderbot, and Hexapod, the most notable obstacle was a sprinkler head with the height of four inches. The orginal Arxterra RoSco is design to travel primarily through flat surfaces and is not equipped to move over obstacles at such height. In order to clear this four-inch sprinkler, the rover team will be examining a design solution that will allow the new rover to achieve the height requirement.

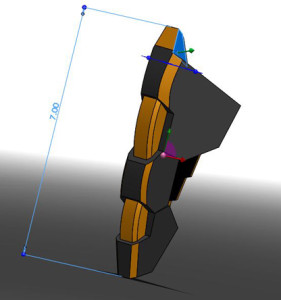

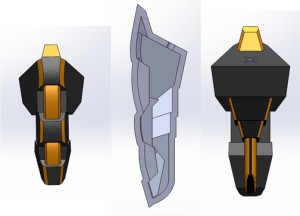

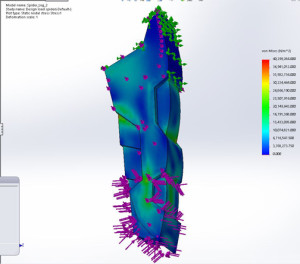

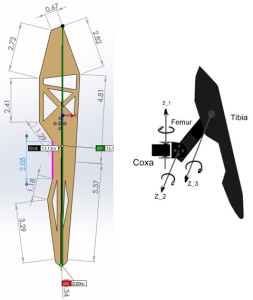

The rover team has agreed that extending the height of the rover is the most simple and efficient design solution in order to fulfill the height requirement. By taking the original chassis (or body) of the rover and extending both sides we will be able to give the rover a height clearance of 4 inches.

In order to extend the sides, several methods will be weighed against each other. One approach will be to have the manufacturing division remodel the chassis of the rover to fit our needs. However, due to time constraints and inefficiency from remodeling the chassis we will opt for a difference solution.

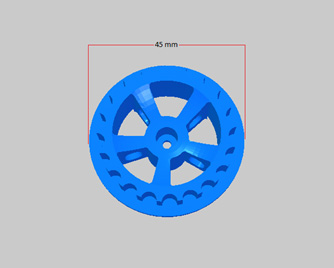

The most efficient solution the rover team decided upon is to mount two wooden height extensions, one to each side of the rover. This will eliminate the need for plastic remodeling and simplify our design solution. Similar holes drilled into the bottom of the wooden extensions will allow us to mount the motors, wheels, and track at the bottom of the extensions. This will thus give the rover a significant height increase.