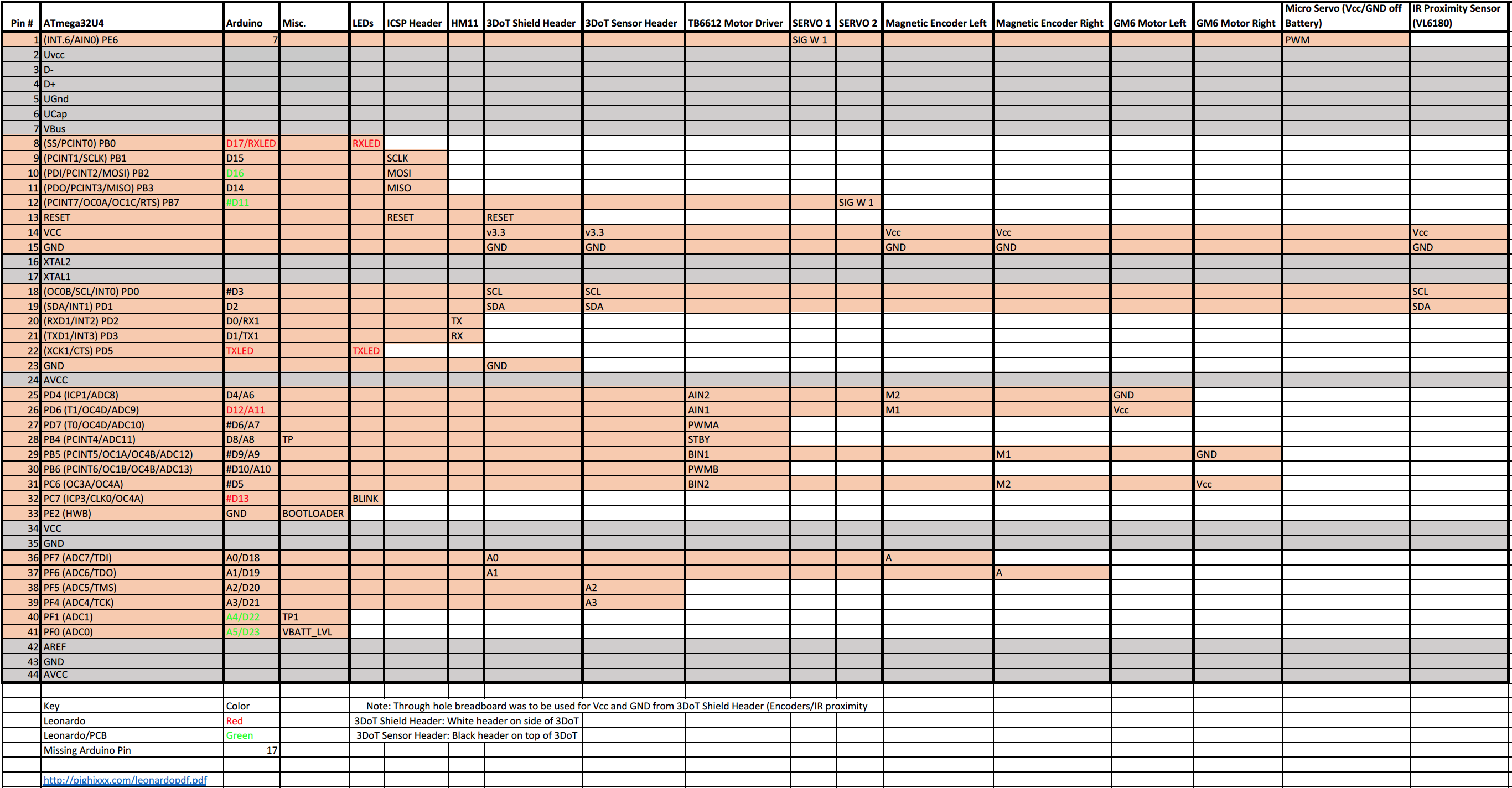

By: Andrew Yi (Mission, System, & Test Engineer) & Matt Shellhammer (Electronics & Control Engineer)

Approved by: Lucas Gutierrez (Project Manager)

Discussion

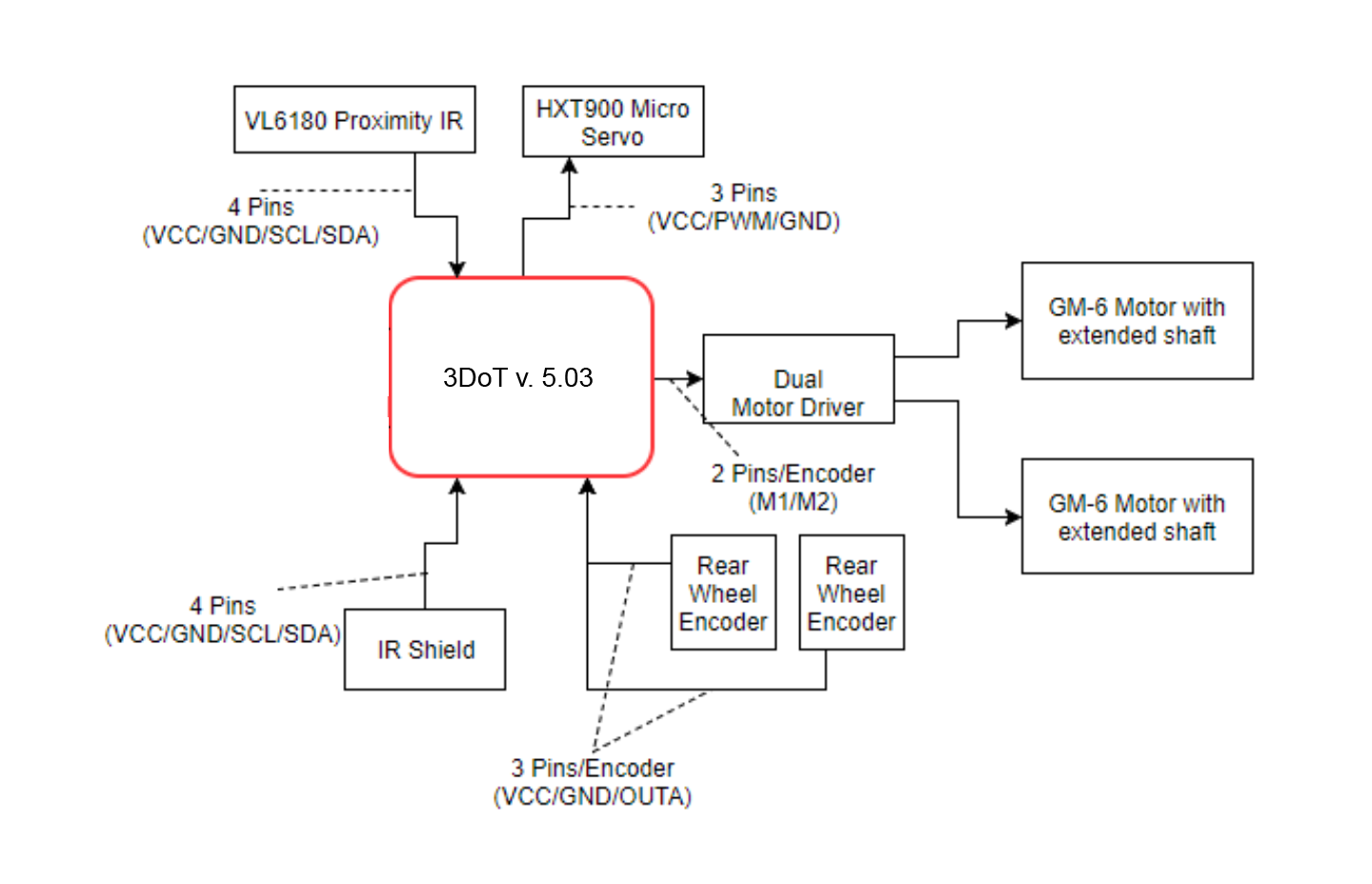

An important factor to operating the ModWheels project is linked to the connectivity of the micro controller and the sensor suite on the ModWheels chassis.

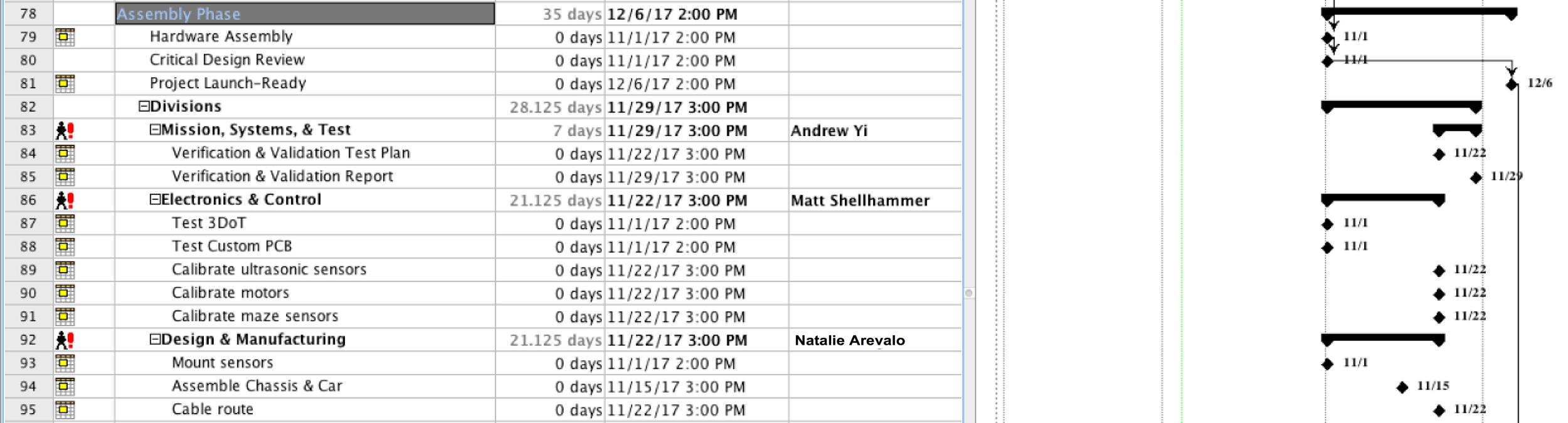

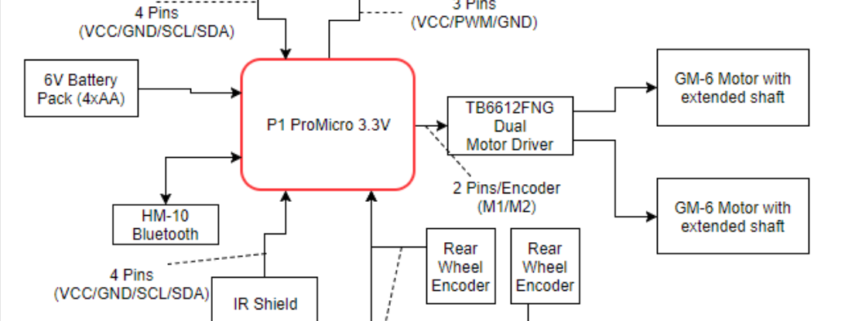

System Block Diagram

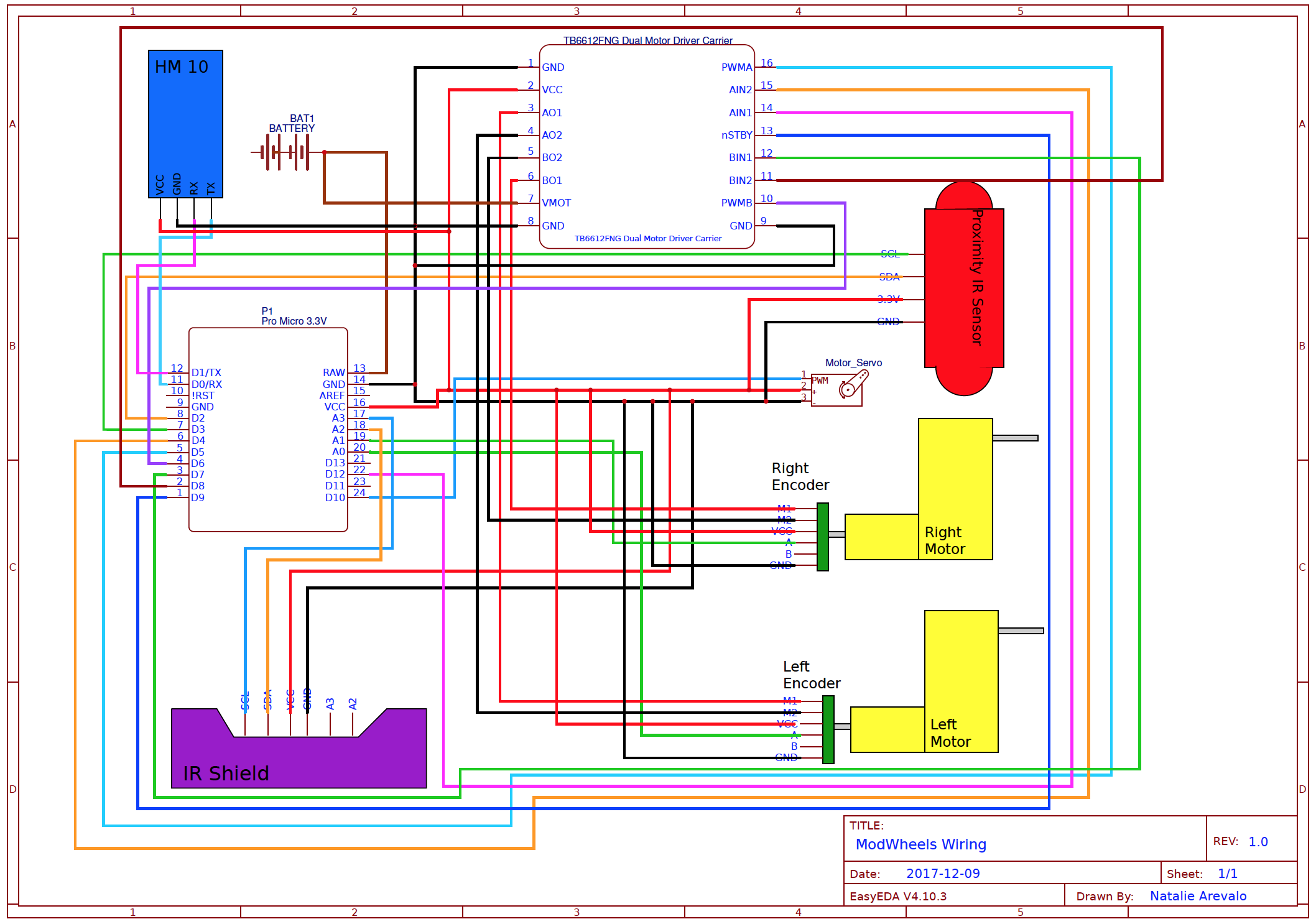

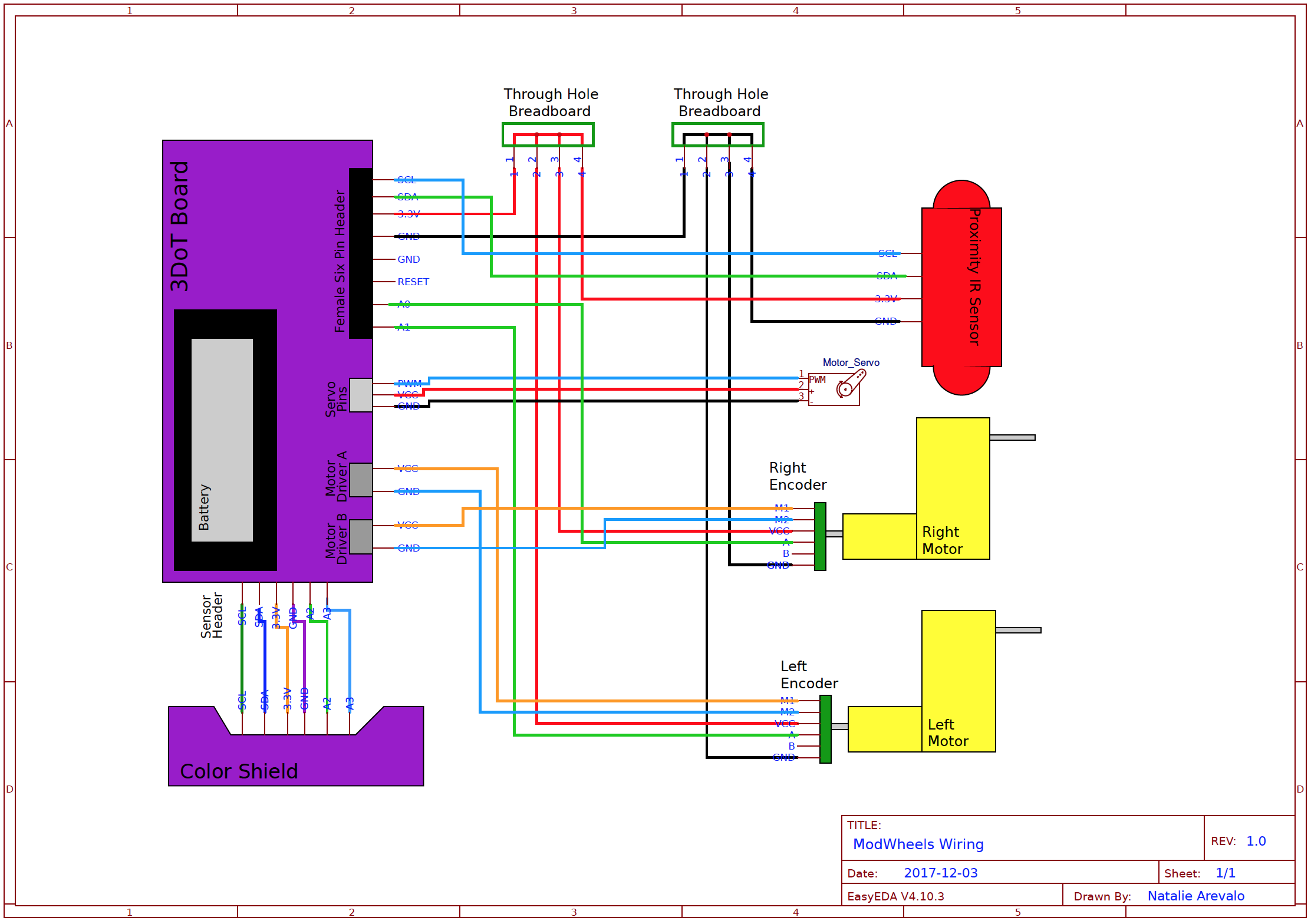

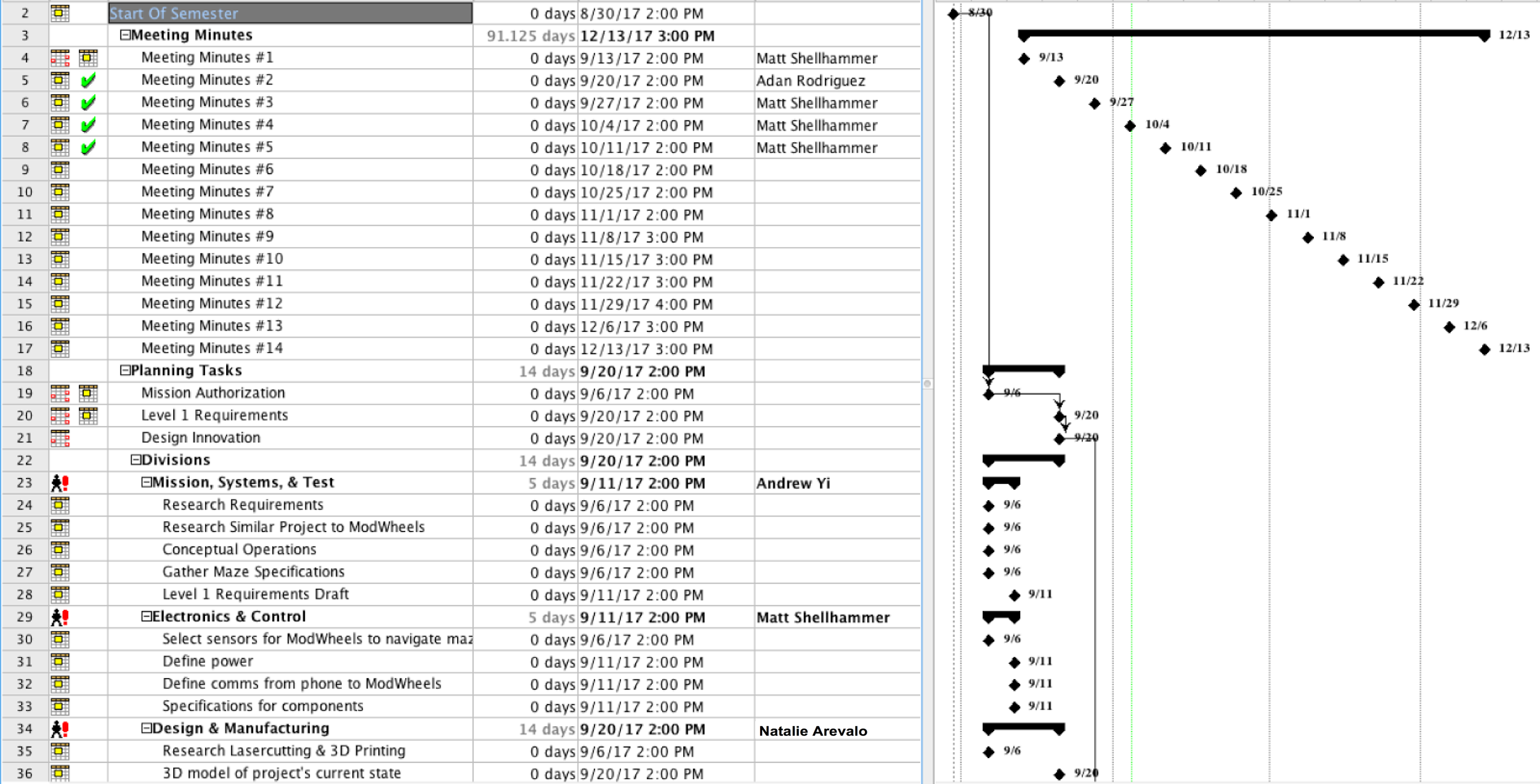

Due to unforeseen circumstances outside of our control, ModWheels was unable to implement a v. 5.03 3DoT micro controller. Instead, the board used for prototyping was used, the SparkFun Pro Micro. The ProMicro microcontroller replaced the 3DoT, but uses the same chip (ATMEGA 32u4). 3DoT implementation should be simple because of the similarities of the 2 microcontrollers. The encoders are connected via analog, sending data to the microcontroller, which then transmits data to the motor driver. 1.5V AA batteries power the toy robot via breadboard connections.

Figure 1: 3DoT v. 5.03 System Block Diagram

Figure 2: Pro Micro System Block Diagram

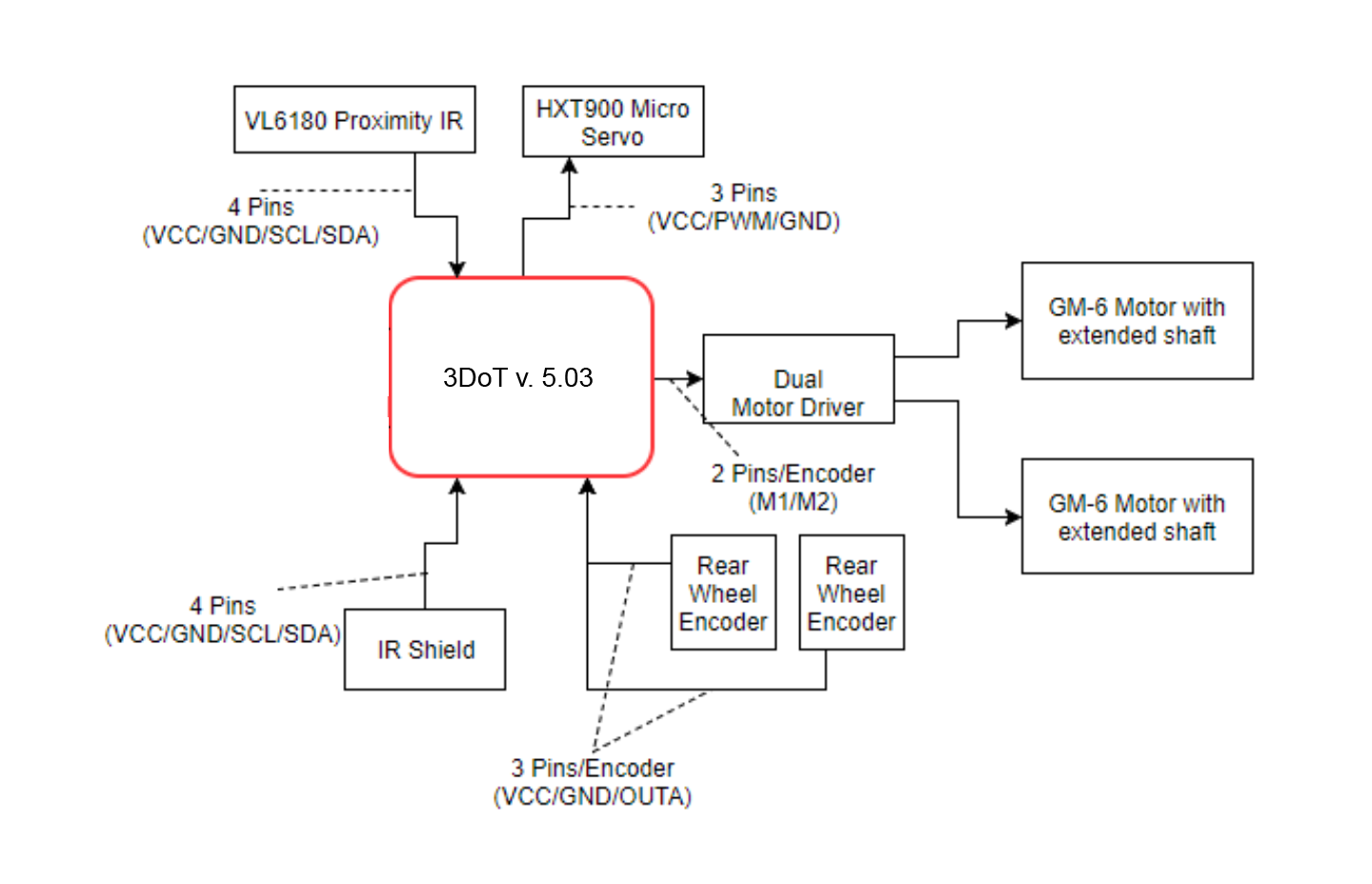

Interface Matrix

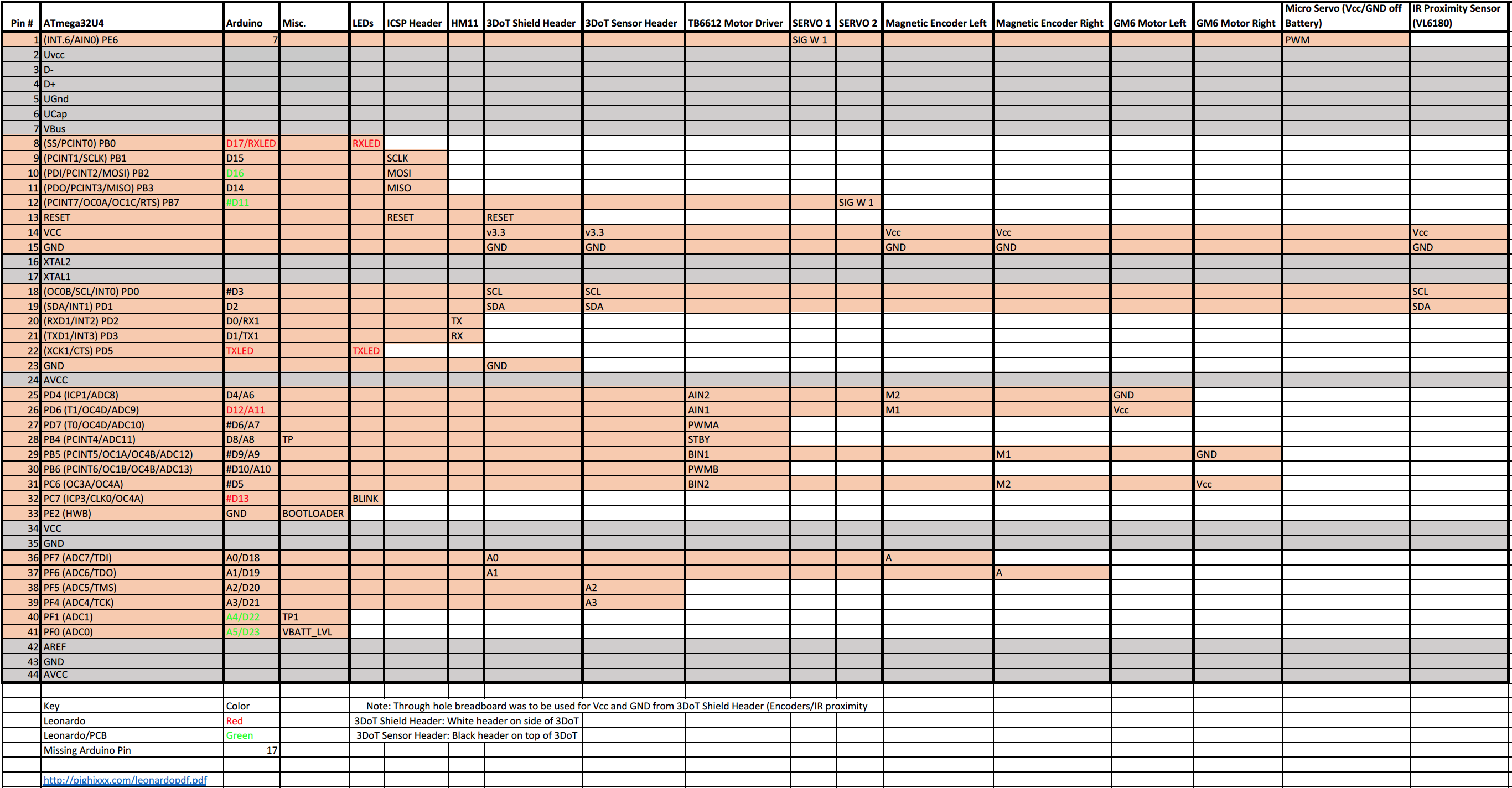

In this interface matrix we show how all peripheral electrical components will be connected to the 3DoT v5.03. ModWheels has a total of six peripheral devices, these devices are a micro servo, two magnetic encoders, two extended shaft GM6 motors, and a IR proximity sensor. These were all to be connected to the 3DoT without a PCB, however instead we were going to use a through hole breadboard to solder headers onto and create more Vcc and GND connections. With this in mind no PCB was required and all peripheral devices have a connection to the 3DoT with extra space for two more analog inputs. Only one channel of the quadrature magnetic encoders were used since the resolution was fine enough to make turns however if there was ever a need to include the second channel for the encoders there is still the remaining two analog connections on the sensor header.

Figure 3: Interface Matrix